Susceptibility of Produce to Infiltration: Risk Factors and Mitigations

ID

FST-320NP

Infiltration: A Food Safety Risk

During post-harvest handling, fresh produce is often pre-cooled, rinsed or washed. When the fresh produce is warmer than the water temperature, the air spaces within the produce compress creating a vacuum effect. This vacuum effect may cause water to be drawn into the produce. The movement of water into the food matrix is referred to as infiltration. Infiltration can cause internal food contamination, if the water that is drawn into the produce is contaminated with pathogens. Even if there are subsequent washing steps targeted at cleaning the surface of the produce, these steps are not effective at eliminating pathogens inside the food matrix. Pathogen infiltration in produce commodities can pose a significant food safety risk, and may lead to possible foodborne outbreaks or recalls, especially in produce that does not go through a kill step, such as cooking, before consumption.

Susceptible Crops and Factors Affecting Infiltration Rates

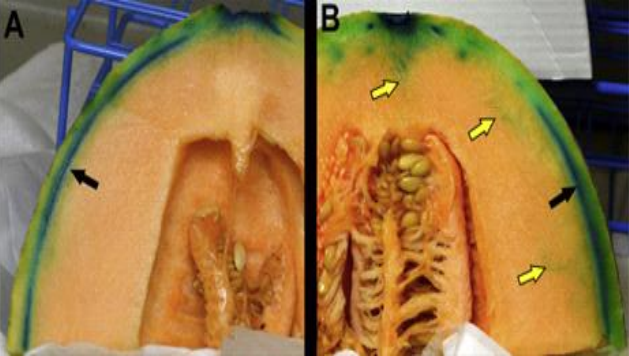

Studies have assessed infiltration of Listeria monocytogenes, Salmonella and other pathogens in different produce such as tomatoes, melons, mangos, oranges, apples and avocados. These studies have shown that pathogen infiltration can occur through different structures of intact produce. For example, in mangos, oranges and avocados the stem or the location where the stem attaches to the fruit (stem scar) is a route for bacterial entrance.

Another example, in apples, the blossom end is the physical structure that allows infiltration. Wounds and damaged surfaces also can contribute to a higher rate of infiltration in produce. Further, research studies suggest that the combination of environmental and physical factors influence infiltration rates. A recent study (5) investigating tomato infiltration indicated that both temperature differential between water and produce, and the time that the tomato spent in the water played an important role in infiltration rates. Other studies suggest that depth of water and produce maturity may also affect infiltration rates.

Strategies to Mitigate Infiltration

To decrease the risk of pathogen infiltration, post-harvest water, (water used during and after harvest) must “be safe and of adequate sanitary quality” (8). For regulatory or third-party audits this means post-tharvest water has zero detectable generic E. coli (organism used as an indicator of potential fecal contamination). Post-harvest water sources include public/municipal water and groundwater, for example well water. Open water sources, such as rivers, streams, and lakes, should not be used for post-harvest activities, unless water is treated, since the risk of contamination is higher.

Whenever possible, producers/packers/processors should implement practices that reduce produce from being submerged in water (where risk of infiltration is highest). For example, using single pass spray bars or forced-air cooling methods. If produce must be submerged in water, it is important to consider 1) quality of produce, 2) use of a sanitizer, 3) temperature of the water and produce, 4) contact time between produce and water.

- Quality/condition of produce: Poor quality produce may increase the risk of infiltration. If produce surfaces are bruised, damaged, or punctured, it may provide an entryway for microorganisms like pathogens to internalize inside produce. Sorting or culling produce before submerging in water can reduce risk of infiltration by removing susceptible produce.

- Use of a sanitizer: Recirculated/reused water, for example water in dump tanks, flumes, and triple sinks, should use a sanitizer. The use of sanitizers in water will reduce and/or eliminate the presence, and survival of pathogens in the water. Sanitizer concentration should be monitored and maintained as stated on the sanitizer label. Sanitizers are regulated by the the Environmental Protection Agency and only some are approved for use on produce (see the Produce Safety Alliance link for approved sanitizers for produce safety:

https://producesafetyalliance.cornell.edu/sites/producesafetyalliance.cornell.edu/files/

shared/documents/PSA-Labeled-Sanitizers-for-Produce.xlsx.) - Temperature of the water and produce: Monitoring and maintaining of appropriate water temperature during post-harvest practices (especially washing) are key practices to reduce infiltration risk. When the warm produce is cooled down using colder post-harvest water a vacuum effect is created. The water surrounding the produce may be drawn into the pulp of the produce increasing the risk of pathogen infiltration. Small temperature differentials (less than 5°C/10°F) between water and produce are not a significant factor contributing to pathogen infiltration. The Florida Department of Agriculture and Consumer Services suggest post-harvest water to be warmer (5°C/10°F) than the produce internal temperature (6).

- Contact time between produce and water: A longer contact time with contaminated water will increase the risk of pathogen infiltration. Infiltration due to temperature differential requires the produce to be in contact with the water for a period of time. Submersion times longer than 5 minutes may increase water and pathogen infiltration (6).

In summary:

Larger temperature differentials between water and produce core or pulp temperatures can lead to higher infiltration rates

Produce submerged in deeper water can be subjected to more water pressure which can cause higher infiltration rates

Longer contact times between water and submerged produce can lead to higher infiltration rates

Produce that is wounded, bruised, punctured or has a stem scar can be more suspectible to infiltration

Post-harvest water should be of good microbial quality, and that quality maintained throughout use

Water should have zero detectable generic E. coli (confirm by testing the water source, for example well)

Water quality can be maintained by monitoring turbidity, sanitizer concentration, temperature and or pH (specifics are based on system; contact extension for more information)

Untreated surface water should not be used for post-harvest activities like submerging produce, unless that water has been properly treated (proper treatment includes set criteria; as well as monitoring, verification, and validation activities).

Addition of a sanitzer can assist in preventing cross-contamination events between water and produce

References

- Contamination of Intact Apples after Immersion in an Aqueous Environment Containing Escherichia coli O157:H7. http://jfoodprotection.org/doi/pdf/10.4315/0362-028X-62.5.444. Accessed February 4, 2019.

- Guidance for Industry: Guide to Minimize Microbial Food Safety Hazards of Fresh-cut Fruits and Vegetables.

https://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatory

Information/ ProducePlantProducts/ucm064458.htm. Accessed February 4, 2019. - Internalization of Listeria monocytogenes in Whole Avocado.

https://www.ncbi.nlm.nih.gov/pubmed/27497134. Accessed February 4, 2019. - Incidence, internalization and behavior of Salmonella in mangoes, var. Tommy Atkins. https://ac-els-cdn-com.ezproxy.lib.vt.edu/S0956713506001757/1-s2.0-S0956713506001757main.pdf?_tid=6a6e2eaf-86ae-46f6-903fb1a3e6568b7a&acdnat=1541103392_bb9eb5db514d7e0710c604d5f8eedca1. Accessed February 4, 2019.

- Influence of Temperature Differential between Tomatoes and Postharvest Water on Salmonella Internalization. http://jfoodprotection.org/doi/abs/10.4315/0362-028X.JFP-15-525?journalCode=food. Accessed February 4, 2019.

- Internalization of Listeria monocytogenes in cantaloupes during dump tank washing and hydrocooling. https://www-sciencedirect-com.ezproxy.lib.vt.edu/science/article/pii/S0168160517302866. Accessed February 4, 2019.

- Potential for Internalization, Growth, and Survival of Salmonella and Escherichia coli O157:H7 in Oranges. http://www.jfoodprotection.org/doi/pdf/10.4315/0362-028X-67.8.1578. Accessed February 4, 2019.

- Poduce Safety Alliance Grower Website (Training Manual Resources).

https://producesafetyalliance.cornell.edu/curriculum/grower-training-manual-links/ Accessed February 4, 2019. - UMass Extension. Vegetable Program. https://ag.umass.edu/vegetable/fact-sheets/infiltration. Accessed February 4, 2019.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, national origin, political affiliation, race, religion, sexual orientation, genetic information, military status, or any other basis protected by law

Publication Date

May 30, 2019