A Beginner’s Guide to Developing a Food Recall Plan

ID

FST-443NP

What is a Recall?

A product recall is a request from a manufacturer or a government agency to return or destroy a food product after the discovery of an issue or product defect that might endanger the consumer or put the maker/seller at risk of legal action. Serious violations’ leading to recalls can include adulteration, or misbranding. Adulteration occurs when there is an addition of a foreign or inferior substance to a food product that misrepresents that product. Misbranding occurs when there is incomplete or inaccurate identification of a product, such as an improper ingredients list or missing allergen notification.Therefore, a recall plan is a written plan put in place ahead of any recall that details how a manufacturing facility reacts to a recall event.

Recall Classifications

There are three classes of recall used by both the Food and Drug Administration and the United States Department of Agriculture: Class 1 (I), Class 2 (II), and Class 3 (III) (Table 1).

What is a Recall Plan?

Recall plans are implemented in the event of a recall to trace products through the supply and distribution chains and stop the spread of the potentially hazardous food products in a timely manner. Certain state and federal regulations (e.g., Preventative Controls for Human Foods Rule) necessitate the development of a written recall plan when a hazard analysis identifies a hazard requiring a preventive control. A well-designed and written recall plan will help to effectively locate the recalled product, remove it from the market, and ensure its disposal.

Recall plans also serve as a roadmap for how a recall should be conducted by the business with defined roles and responsibilities to reduce confusion and inaccuracy during the trying time of a recall. It serves as a guide for the company to follow if a situation requiring a recall presents itself. The goal of this publication is to provide information to help producers and food business owners understand the importance and key components of a recall plan.

Table 1. Recall Classifications

Class |

Description |

Class I |

Class I recalls are the most serious and involve a health hazard situation in which there is a reasonable probability that eating the food will cause health problems or death. |

Class II |

Class II recalls involve a potential health hazard situation in which there is a remote probability of adverse health consequences from eating the food. |

Class III |

Class III recalls involve a situation in which eating the food will not cause adverse health consequences. |

Recall Plan Requirements

A recall plan must be written and implemented to ensure that in the case of adverse events, action can be taken as quickly as possible. The written recall plan must describe procedures:

- Determining if a recall is needed

- Locating and isolating shipments of all affected lots of products to consignees

- Notifying direct customers and consignees of the product

- Notifying the public when necessary

- Procedures for product replenishment

- Appropriately disposing of recalled product

- Conducting effectiveness checks to verify that the recall is carried out and review the plan accuracy

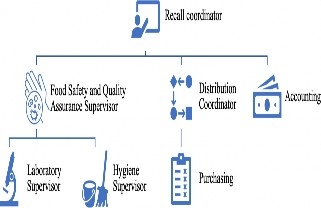

Assembling a Recall Team

When you consider how a recall in your company would be managed, you may be developing a long list of responsibilities spanning a range of positions. If a recall is needed, it is important to know who will be overseeing each responsibility, and who will be responsible to coordinate the recall efforts. Therefore, it is helpful to start developing your recall plan by establishing a list of specific people who will serve on your recall team. The recall team should be made up of individuals from a variety of departments, and each recall team member should act as the leader within their department.

Your local FDA Recall Coordinator and State Recall Coordinator should also be part of your recall team. While these two coordinators are not employees of your company, they should be among the first to be notified of a recall as they will play an active role on your team. You can find the FDA district recall coordinator at: www.fda.gov/Safety/Recalls/IndustryGuidance/ucm1 29334.html.

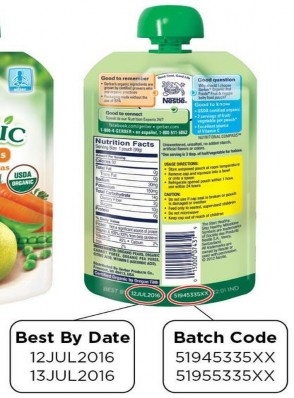

Identify the Scope of the Recall

To successfully execute a recall, you need to accurately identify the specific products, and lots involved. This includes being able to identify products by:

batch number

serial number

lot number

expiration date

UPC codes

shipping dates

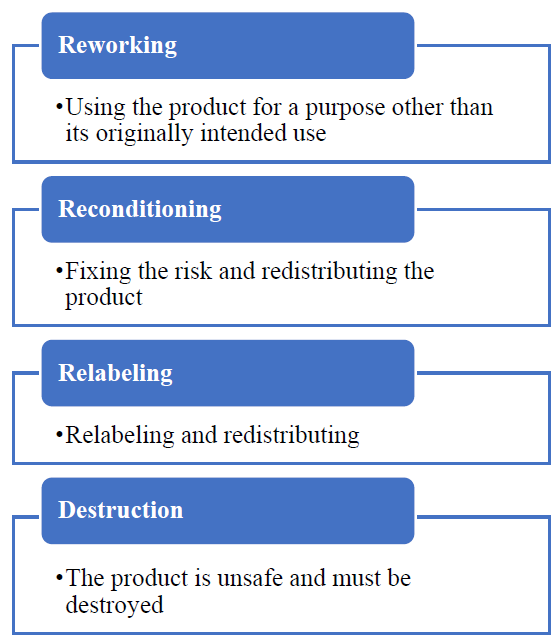

Decide What to Do with the Recalled Food

Depending on the hazard and the food matrix, the recall team will need to decide how to properly handle the recalled products. While severe recall situations might warrant the complete destruction of the product, situations such as mislabeling may allow for redistribution, reworking, reconditioning, or relabeling. It is helpful to think of hypothetical reasons for your products recall and practical guidelines for disposal. Options for disposition:

Effectiveness Checks

Effectiveness checks are used to verify that the recall is successfully removing product from distribution and away from consumers. It is important to check and provide evidence that product disposition instructions were followed at points along the distribution chain. Recall effectiveness checks should be conducted with every affected receiver of affected food product consignees to verify receipt of the product recall notice and that appropriate actions have been taken. These checks can be conducted electronically, by phone and/or by personal visit, or by a third-party firm. Effectiveness checks should be completed for 100% of consignees receiving recalled product.

Recall Practice Exercises

Conducting a recall simulation is a practical way to test the effectiveness and ensure the success of your recall plan. A mock recall practice exercise will allow the recall team to become familiar with their responsibilities and gives them time to communicate any concerns they have about the plan. It allows a business to be prepared for the actual recall event that could cost extra time, money and damaged reputation if not done effectively.

Future Actions

If a food recall occurs for your product, it is important to review your food safety plan in order to prevent future issues. If the recall was the result of a new hazard, the food safety plan should be updated to include preventative controls for that hazard. If the recall was due to inadequacy in executing the food safety plan, worker trainings or equipment upgrades may be needed. Additionally, a communication plan should be developed; plans may target media, employees, buyers, or other various audiences.

References and Resources

Food and Drug Administration. (2022). Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry. Chapter 14: Recall Plan. Available at: https://www.fda.gov/media/131287/download

Food and Drug Administration. (2022). Industry Guidance For Recalls. Available at: https://www.fda.gov/safety/recalls-market-withdrawals-safety-alerts/industry-guidance-recalls

Food Marketing Institute. (2020) Guidance for Retailers: Product Recalls. Available at: https://www.fmi.org/docs/default-source/food-safety/guidance-for-food-retail-product-recall.pdf?sfvrsn=2

Mohan, A., Fortner, R., and Chatterjee, D. (2019). Developing A Recall Plan: A Guide for Small Food Processing Facilities. Available at: https://secure.caes.uga.edu/extension/publications/files/pdf/B%201509_2.PDF

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, national origin, political affiliation, race, religion, sexual orientation, genetic information, military status, or any other basis protected by law

Publication Date

February 3, 2023