Hydroponic Production of Edible Crops: Deep Water Culture (DWC) Systems

ID

SPES-464NP

Introduction

With the increasing number of controlled environment agriculture farms (CEA), Virginia Cooperative Extension (VCE) is working closely with specialty crop growers to address the challenges of establishing and managing hydroponic greenhouse operations. Growers interested in producing food crops in controlled environments can use several different types of hydroponic systems (Resh 2017).

One type of hydroponic system is called deep water culture (DWC) also known as a floating or raft system (Figure 1). In the 1980s, Dr. Merle Jensen (Environmental Research Lab at University of Arizona) developed a raceway system that was relatively deep (6 to 8 inches) compared to other existing water culture methods. He successfully demonstrated this production system that has been adopted by commercial growers and hobbyists to grow leafy greens. DWC has also been used in the tobacco industry to grow transplants for later planting into conventional field production.

This publication will give an overview of DWC systems and will include descriptions and images of standard set-ups. Growers should consider that there are many variations on the main components listed here and choose designs and materials that fit into their production scheme.

Set-Up and Design

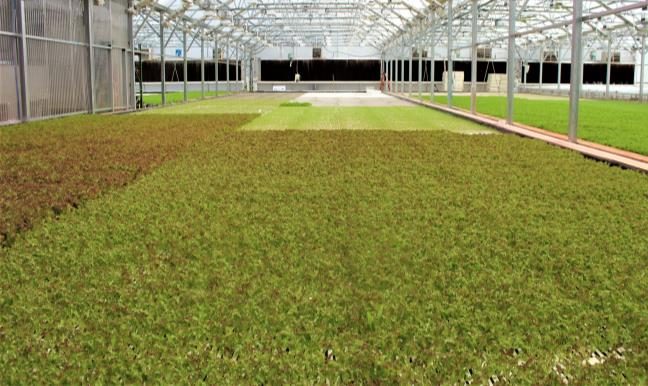

DWC systems are scalable and can be constructed of different materials; however, the major components are similar. All DWC systems have a production pond, plant rafts/holder, pumping system for nutrient solution distribution, and oxygenation (Figure 2). In a well-designed DWC system, nutrient solution is circulated throughout the pond to ensure proper distribution to all plants. In addition, plant production rafts float from a planting area to a harvest area during one crop cycle, allowing for more efficiency in these processes. Most DWC systems are generally less complex compared to the number of components in other hydroponic systems.

Plant Production Pond

The plant production area is essentially a “pond” in most DWC systems. However, DWC can also use some type of a tank or reservoir to contain the plants. Containers of various shape and size can be used for this purpose (Figure 3). Growers should consider availability, price, overall design, shape and size when choosing the DWC plant production area.

The pond of most DWC systems can be built from dimensional lumber usually 2 inches nominal thickness. Depth of the pond can vary between 4 to 12 inches based on the desired volume of the pond. The lumber is used to create a frame or perimeter for the pond. Corners are screwed together or connected with corner brackets. Growers should consider the outward forces pushing on the sides of the framing from the water and support bracing should be added periodically to counteract these forces. Polyethylene sheeting (plastic) is used to line the pond creating a waterproof barrier (Figure 4).

Care should be taken when building the pond especially when placing the liner in the system to ensure it is not punctured. Small holes made during the construction phase could create small leaks in the pond that are difficult to find during production.

Growers should consider placing material such as insulation boards on the bottom/floor of the pond to protect against abrasive material that could puncture the plastic. As the insulation material sits under the plastic it can also act as a barrier to temperature fluctuation in the nutrient solution in the pond. The simplest method of attaching the plastic liner is to use batten tape and staples to secure it to the lumber. Once the framework is constructed and the liner is in place the pond can be filled with water.

Plant Rafts

Seedlings are placed on floating rafts or some type of pond covering. These rafts can be made of various materials. Commercially available rafts are made of heat-sealed polystyrene resins. Raft size is usually 2’ by 4’ but can vary based on need. Growers should consider a raft size that is easy to handle during harvest as mature plants can cause a large raft to be heavy and awkward to move (Figure 5).

The number of plant spaces and plant space type vary based on desired density for specific plant needs. Usually lettuce rafts have plant spaces that are 8 inches apart. Rafts can also be made by the grower from insulation boards purchased from a home improvement store. Customized plant spaces can be cut out or drilled, although care should be taken since some insulation boards will shed small flakes of material from the cut edge.

Occasionally DWC systems will have a pond/reservoir covering that does not float but simply sits above the pond and holds the seedlings with their roots in the nutrient solution. These coverings are usually some type of plastic material (Figure 6).

Growers should consider one advantage of a floating raft system is the ability to move rafts with little effort from one area of the pond to another. This conveyer effect allows the grower to plant in one end of the pond and move rafts to the other end for harvest as needed (Figure 7).

Nutrient Solution Movement

Nutrient solution is added directly to the plant production pond and is moved and circulated with a pump. In many systems a submersible pump is used inside the pond while other systems use a pool-type centrifugal pump. These pumps should be rated for continuous duty and sized for good circulation of nutrients in the pond. Growers should consult the pump labeling or manufacturer for pump performance charts. A venturi can be added to the output of the pumping system to inject air into the pond which can aid in maintaining high dissolved oxygen levels. In smaller systems an air pump with an attached air line and diffuser can be added to the system to aid in movement of nutrient solution (Figure 8).

Crops

Occasionally fruiting crops such as strawberries, peppers, tomatoes and cucumbers are grown in these systems. However, most often, low growing, leafy greens and culinary herbs are grown in DWC systems. Various types of lettuce work very well in a DWC system such as butterhead, romaine, oakleaf, multileaf. Other salad greens like sorrel, arugula, tatsoi, mache, frisee work well in this type of system (Figure 9).

Many of these plant types have different colors and textures which can work well in bagged leafy green mixes. Cultivars that are adapted to greenhouse conditions can be found from seed vendors. Growers should consider market value/need, plant habit, maturity date, and resistance to disease and physiological problems when selecting plant types and cultivars.

Propagation is from seed and usually occurs in a separate area from the main system (Figure 10). Raw seed is used in some cases but very commonly pelleted seeds (raw seeds coated with an inert material to yield a consistent size and shape) are used.

Seedlings planted into DWC rafts are typically produced by seeding into media made of materials like rockwool, foam or compressed peat/coir. These materials come as a cube that is sized to fit into NFT channels and floating rafts, and also have a dimpled depression on the top to accommodate a seed. All of these types of media hold moisture well and allow for uniform germination. After germination, seedlings are given partial strength nutrient solution as the inert germination media adds no nutrients to the plants. Once larger, seedlings are placed on the DWC rafts (Figure 11).

Nutrient Solution Management

Nutrient solution can be made by mixing fertilizers with water in a container which is then circulated in the plant production pond. Water soluble powdered fertilizers and liquid premixed fertilizers are most often used. Fertilizer mixing instructions are given by fertilizer suppliers based on the crop being grown and are on the fertilizer packaging. Growers should consider a fertilizer program that provides all the necessary macro and micro elements needed for optimum growth.

One nutrient solution example would be to provide all the needed nutrients to the plants by using a complete fertilizer such as 8-15-36 along with calcium nitrate and magnesium sulfate. These fertilizers, mixed in the correct amounts based on the labeling instructions for the volume of water in the reservoir, should be mixed separately then added to the reservoir (Figure 12). After the addition of the fertilizer and agitation of the tank, the pump can be turned on to provide nutrient solution to the system.

Water quality meters are necessary to the management of the nutrient solution in the DWC system including meters for electrical conductivity (EC), pH, and dissolved oxygen (DO) (Figure 13). Meters vary in price and quality. Growers should consider meter longevity, reliability, price and accuracy when purchasing. Electric conductivity (EC) and pH should be checked two to three times each week. EC measurement lets the grower know if the total amount of fertilizer in solution has changed over time. Adjustment of fertilizer strength, based on the EC reading of the solution, can be made through addition of stock fertilizer solution or water. Many leafy greens perform well at EC 1.2 to 2.0 mS/cm. The pH measurement lets the grower know about the acidic or basic nature of the solution, which can affect nutrient uptake by the plants. Most plants grown in these systems perform well at pH 5.5 to 6.2.

Conclusion

Deep water culture (DWC) can be a great way to grow crops. This publication gives a general overview of DWC however potential growers should investigate specific options for their unique situation. Growers should consider contacting their local Cooperative Extension office for more information.

References

Resh, H. 2017. Hydroponic Food Production, 7th ed. CRC Press.

Additional Resources

Cornell College of Agriculture and Life Science

https://cea.cals.cornell.edu/

Ohio State University

https://u.osu.edu/greenhouse/hydroponic-crop-program-introduction/

North Carolina State University

https://cals.ncsu.edu/horticultural-science/research/greenhouse-vegetable-production/

Pennsylvania State Extension

https://extension.psu.edu/hydroponics-systems-and-principles-of-plant-nutrition-essential-nutrients-function-deficiency-and-excess

Sallenave, R. and R. C. Shultz. 2022. Hydroponics: Water-saving Farming for New Mexico's Arid Environment. New Mexico State University Cooperative Extension Service.

University of Arizona

https://ceac.arizona.edu/

University of Minnesota Extension

https://extension.umn.edu/how/small-scale-hydroponics#growing-systems-2644460

Acknowledgements

This work was supported by the Virginia Department of Agriculture and Consumer Services (VDACS) Specialty Crop Block Grant Program, Award Number 2020-548, from the U.S. Department of Agriculture’s (USDA) Agricultural Marketing Service. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the authors and do not necessarily reflect the view of the US. Department of Agriculture.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, national origin, political affiliation, race, religion, sexual orientation, genetic information, military status, or any other basis protected by law

Publication Date

July 19, 2023