Hops in Virginia: Quality Changes During Cone Ripeness

ID

SPES-529NP

Introduction

Hop (Humulus lupulus L.) is an essential ingredient for beer brewing. Although hops are a relatively minor ingredient in the brewing process, it almost exclusively contributes to the bittering taste and hoppy aroma in beers. The primary hop production region in U.S. centers around the Pacific Northwest including Washington, Oregon, and Idaho (Siegle and Scoggins, 2019). Although hop production in Virginia has been limited by climate and latitude, the number of craft breweries in Virginia has steadily grown in recent years. In 2022, there are 314 licensed craft breweries in Virginia, representing a vibrant industry with a $1.7 billion total economic impact (Reynolds, 2022). According to the hop grower survey distributed by Virginia Cooperative Extension, the most popular hop cultivars among Virginia hop growers are Cascade, Chinook, and Nugget, consistently taking up more than 60% of hop plants grown from 2015 to 2018 (Siegle and Scoggins, 2019).

To produce high-quality hop cones, it is important to investigate the factors affecting their quality. The yield and quality of hop cones can be affected by many factors, such as hop cultivars, production location, and climate (Sharp, Townsend, Qian, and Shellhammer, 2014). Different hop cultivars have distinct flavor characteristics due to different levels of bittering acids and aroma compounds present in the lupulin glands of hop cones (Steenackers, De Cooman, and De Vos, 2015). For example, Cascade hops are usually considered to be the cultivar with an herbal, citrus, and sweet note because Cascade hop cones contain a high level of compounds representing these aroma attributes, such as linalool, geraniol, and L-calamenene (Su and Yin, 2021). With regards to production location and climate, the summer daylight in Virginia is shorter compared with northwestern states in the U.S., which could cause low blooming and yield of hop plants. Besides, increased heat and humidity also lead to challenges such as downy mildew and fungal diseases (Garber, Morgan, Scoggins, & Seigle, 2019).

Hop cone ripeness is a dynamic process in which the chemical composition can change dramatically; thus, it can be challenging for hop growers to determine the time of harvest for optimum cone ripeness and quality. A few previous studies have showed the impact of ripening levels on the hop cone chemistry and the influence on the sensory quality of beers. For example, Cascade and Willamette hops harvested from Oregon over a 3-week window reported an increased essential oil content, primarily attributing to increased levels of α-pinene, limonene, and myrcene (Sharp et al., 2014).

Besides, the beers brewed with hops from different ripening levels showed distinct sensory differences, which highlighted the importance of cone ripeness. Lafontaine et al. studied the ripeness impact of Cascade hop on dry-hopping beers. Dry-hopping is a brewing technique in which hops were added in fermented or partially fermented beer, with the intension of increasing hop aroma without adding bitterness of final products (Lafontaine, Varnum, Roland, Delpech, Dagan, Vollmer, Kishimoto, & Shellhammer, 2019). Results suggested that fully matured Cascade hops were more suitable for dry- hopping as much intense aroma was observed possibly due to elevated amounts of terpene alcohols and free thiols (Lafontanine, 2019). However, previous studies were mainly conducted in the Pacific

Northwest of the U.S., and little is known on the variations in the chemical profile of Virginia hops during cone ripeness.

In this publication, we investigated the changes in chemical composition of Cascade, Chinook, and Nugget hops during ripening from three farms in Virginia, in order to provide some baseline information for regional growers. We also included several recipes using hops as an ingredient for culinary purposes.

Quality Changes During Hop Cone Ripeness

During the growing seasons of 2021 and 2022, Cascade, Chinook, and Nugget hop cones were harvested at regular intervals throughout the ripening period, spanning from late July to early September. The hop plants were grown in three different farms in VA, all located at a similar latitude (36.76-37.43 °N). Detailed sample information is listed below (Table 1).

Immediately after harvest, fresh samples were stored carefully in clear plastic vacuum bags at ~4°C. Samples were then transported to the flavor lab of the Food Science and Technology department at Virginia Tech, where average cone weight, moisture content and aroma content were analyzed for each sample.

Location |

Hop cultivar |

Sampling dates |

|||||

|---|---|---|---|---|---|---|---|

Petersburg, VA |

Cascade |

07/22/2021 |

07/26/2021 |

07/29/2021 |

08/02/2021 |

08/05/2021 |

08/09/2021 |

|

Chinook |

08/02/2021 |

08/05/2021 |

08/09/2021 |

08/12/2021 |

08/16/2021 |

08/19/2021 |

Shipman, VA |

Cascade |

08/03/2022 |

08/05/2022 |

08/08/2022 |

08/10/2022 |

08/12/2022 |

08/14/2022 |

|

Nugget |

08/20/2022 |

08/22/2022 |

08/24/2022 |

08/26/2022 |

08/28/2022 |

08/30/2022 |

Meadowvie w, VA |

Cascade |

08/12/2022 |

08/17/2022 |

08/22/2022 |

08/25/2022 |

NA |

NA |

|

Chinook |

08/22/2022 |

08/25/2022 |

08/30/2022 |

09/02/2022 |

NA |

NA |

NA=Not Applicable

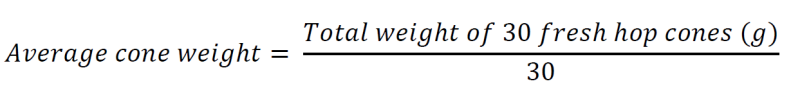

Average cone weight: a total of 30 fresh hop cones were randomly selected from each sample and weighed; average cone weight was calculated based on the following formula:

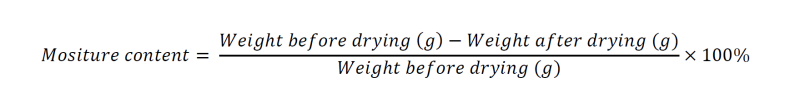

Moisture content: approximately 2.5g of fresh hop cones from 2021 season and 10g of fresh hop cones from 2022 season hops and were dried at 105°C for an hour. Sample weight was measured before and after drying, and the moisture content were calculated based on the following formula:

Aroma content: aroma compounds from hop cones were extracted by solid-phase micro extraction (SPME) and identified and quantified by gas chromatography-mass spectrum (GC-MS). The method is adapted from a previous publication from the Virginia Tech flavor lab (Su and Yin, 2021). A total of 11 aroma compounds were selected based on their contribution to hop aroma characteristics, such as high flavor dilution factors and odor activity values. A high flavor dilution factor indicates that an aroma compound remains detectable by the human nose even at low concentrations; and a high odor activity value means that a volatile compound possesses a particularly potent aroma (Reineccius, 2005). The quantitative analysis of aroma-active compounds was performed with two internal standards, decane and 2-octanol, and standard addition method by GC-MS. Briefly, standards of the selected aroma compounds with known concentrations were added to blank hop samples, and the signal (peak area of the selected aroma compounds and internal standards) produced by GC-MS was recorded. Bases on the GC-MS peak area, the known concentration of aroma compounds, as well as the concentrations of internal standards, a calibration curve of each aroma compound can be built, thus the aroma concentration of unknown samples can be calculated. The aroma content is calculated by adding up the concentrations of the 11 aroma-active compounds of interest. The selected aroma compounds and their odor descriptions are listed in Table 2.

Compound name |

Odor description |

|---|---|

β-Myrcene |

balsamic, woody, herbal |

Methyl octanoate |

sweet, fruity, waxy, herbal |

Methyl nonanoate |

green, sweet, caramel, fruity |

Linalool |

sweet, floral, citrus |

Caryophyllene |

oily, fruity, woody, spicy |

cis-β-Farnesene a |

woody, green, cinnamon |

Humulene |

woody, musty |

Geraniol acetate a |

floral, rosy |

Geraniol |

orange, citrus |

Germacrene B b |

rosy, sweet |

Caryophyllene oxide |

woody, waxy, green, herbal, spicy |

a Aroma compound identified only in Cascade hops. b Aroma compound identified only in Chinook hops.

Cascade Hops

The changes in quality parameters of Cascade hop cones during ripening are shown in Table 3-5. The average cone weight of Cascade hops during the harvest seasons of 2021 and 2022 ranged from 0.50-

0.78 g and 0.42-0.77 g, respectively. A decrease in the average cone weight can be observed during the late ripening stage for hop cones harvest, while the dry mass of hop cones was relatively consistent over the course.

An increased trend in the aroma content was observed for both Petersburg and Shipman Cascade hops at the early stage of ripeness. The highest aroma content of Petersburg hops occurred around 08/05/2021 while the Shipman hops was peaked around 08/10/2022, after which the total aroma content started to decrease. For Cascade hops harvested from Meadowview, the aroma content peaked on between 08/12/2022 and 08/17/2022, which might have indicated the fact that our harvest practices missed the early ripening and/or optimal window. Overall, among our received samples, 2021 harvest seemed to possess significantly higher aroma content compared to 2022 harvest, which suggested seasonal variations. For 2022 season, Cascade from Shipman were more aromatic compared to those from Meadowview. This variation could also be ascribed to the random sampling from individual plants in hop yard.

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|

|---|---|---|---|---|

07/22/2021 |

0.78 |

73.39 |

3623.99 |

|

07/26/2021 |

0.60 |

75.47 |

4750.35 |

|

07/29/2021 |

0.59 |

74.64 |

7181.87 |

|

08/02/2021 |

0.65 |

75.26 |

6767.05 |

|

08/05/2021 |

0.69 |

75.94 |

8168.38 |

|

08/09/2021 |

0.50 |

74.71 |

7629.88 |

|

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|

|---|---|---|---|---|

08/03/2022 |

0.63 |

74.75 |

3300.10 |

|

08/05/2022 |

0.77 |

74.65 |

3522.36 |

|

08/08/2022 |

0.62 |

74.49 |

3535.29 |

|

08/10/2022 |

0.57 |

73.60 |

4393.16 |

|

08/12/2022 |

0.64 |

71.76 |

3549.79 |

|

08/14/2022 |

0.58 |

72.79 |

2643.00 |

|

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|---|---|---|---|

08/12/2022 |

0.57 |

78.23 |

2907.65 |

08/17/2022 |

0.49 |

76.27 |

2947.46 |

08/22/2022 |

0.53 |

79.49 |

2716.68 |

08/25/2022 |

0.42 |

77.01 |

1576.54 |

Chinook Hops

The changes of Chinook hop cones during ripening are shown in Table 6 and Table 7. For hop cones collected from Petersburg, the cone weight and moisture content were higher during early ripening dates and reduced afterwards. For hop cones collected from Meadowview, the sample collected on 08/25/2022 has a high moisture content, which could be caused by a rainfall a few days before the harvest.

For aroma content, the peak for Petersburg Chinook hops appeared around the harvest date of 08/09/2021, where the aroma content was 8228.04 μg/g. The peak aroma content was 3578.08 μg/g from 2022 harvest for Chinook hops from Meadowview. Despite of harvesting from two locations from separate seasons, it would be reasonable to suspect the Chinook might have performed better for aroma contents in 2021 compared to 2022, as the same trend was observed for Cascade.

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|---|---|---|---|

08/02/2021 |

0.71 |

75.91 |

2013.93 |

08/05/2021 |

0.64 |

75.11 |

5009.31 |

08/09/2021 |

0.79 |

76.38 |

8228.04 |

08/12/2021 |

0.57 |

74.20 |

5332.80 |

08/16/2021 |

0.55 |

74.65 |

4304.65 |

08/19/2021 |

0.66 |

72.81 |

5871.25 |

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|---|---|---|---|

08/22/2022 |

0.43 |

76.76 |

1859.60 |

08/25/2022 |

0.53 |

81.54 |

3148.62 |

08/30/2022 |

0.38 |

76.48 |

2955.40 |

09/02/2022 |

0.49 |

73.17 |

3578.08 |

Nugget Hops

The changes of Nugget hop cones during ripening are shown in Table 8. Nugget hop cone weight and moisture content decreased at a later ripening date, however, the aroma content gradually increased. The highest aroma content of 4455.06 μg/g was observed on 08/30/2022.

Harvest date |

Average cone weight (g) |

Moisture content (%) |

Aroma content (μg/g dried basis) |

|---|---|---|---|

08/20/2022 |

0.57 |

75.81 |

1407.21 |

08/22/2022 |

0.50 |

74.73 |

2958.09 |

08/24/2022 |

0.45 |

75.55 |

2847.70 |

08/26/2022 |

0.41 |

74.00 |

2635.36 |

08/28/2022 |

0.50 |

74.41 |

3991.14 |

08/30/2022 |

0.46 |

72.45 |

4455.06 |

In summary, aroma content does change during ripening process of hop cones, with the general observation of reaching the peak at a relatively late harvest date, where the average cone size is smaller, and the moisture content is lower. However, it requires a lot of harvesting experiences to not to miss the peak content. Although the selected aroma compounds were meticulously analyzed (data not shown), we were not able to find one specific aroma compound as the indicator or marker for predicting the optimum timing for harvest. The level of aroma content in hop cones is highly affected by cultivar, growing season, terroir, agronomic practices, and many other factors, as we can see the hops from the 2021 growing season in Petersburg have the highest aroma content, regardless of hop cultivar. The moisture content of hop cones can be a good deciding indicator for timely harvest. It is, however, easily influenced by the rainfall. As local hops are commonly sold in fresh by weight, growers also want to consider a proper selling point at which the fresh weight and aroma quality are both justified at a reasonable price range. Data from this study indicates that the aroma content of hop cones is relatively

high when the moisture content of hop cones centers around 72%. Additionally, other quality metrices such as cone weight, color, or bittering acid content should also be considered when possible during harvest.

Ways to Incorporate Hops into Your Recipes

Hops Salt

Use as a cooking salt or finishing salt for your everyday meals to impart the aromas of your favorite hops without adding bitterness!

Yield: 8 oz Prep time: 5 minutes Total time: 5 minutes

Hop Pellets Method

Ingredients:

12 tbsp coarse sea salt

4 tbsp hop pellets Instructions:

- Using a mortar and pestle or a spice grinder, grind the hop pellets to a fine powder.

- In a bowl, mix 4 tbsp of your freshly ground hop powder into 12 tbsp of coarse sea salt. Rule of thumb: 1 tsp hop pellets for each 1 tbsp of sea salt.

- Let the hops infuse the salt for at least 24 hours before using.

Dried Hop Flowers (Cones) Method

Ingredients:

1 cup coarse sea salt

4 - 6 hop flowers, as desired Instructions:

- Fill an airtight container with a layer of salt and lay one or two hop flowers on tops.

- Alternate with more salt and more hop flowers until filled.

- Close the lid, give a gentle shake, and let infuse for 24-48 hours before using.

https://www.craftbeering.com/how-to-make-hop-salt/

Hops Salted Caramel Sauce

Use as a glaze, drizzle on your ice cream, dip for fruit or even cheese, or pair with IPA/pale ale/stout!

Yield: 8 oz. Prep time: 5 minutes Cook time: 5 minutes Total time: 10 minutes.

Ingredients:

1 stick unsalted butter

1 cup brown sugar

4 tbsp of regular whipping cream, not heavy whipping cream

Hops salt to taste, recommended at least ½ tsp Instructions:

- In a saucepan over medium heat combine the butter, brown sugar, and whipping cream.

- Stir until smooth and bring to a simmer.

- Let simmer for 4 mins.

- Turn off heat and sprinkle with the hops salt.

- Stir and remove from the stove, let cool off and thicken for a few minutes.

- When it is comfortable to the touch, taste it and add more hops salt if desired.

- Stir and transfer to an airtight glass container or use right away.

- Store in the refrigerator and warm up in a water bath or in the microwave for a few seconds before next use.

https://www.craftbeering.com/hops-salted-caramel-sauce-diy-how-to-make/

Hoppy Cranberry Simple Syrup

Add a unique and delicious spin to your glazes, cocktails, and dinner roasts with this hoppy cranberry simple syrup! Use as a glaze on your panna cotta or infused with a refreshing sangria for sweetness and a touch of astringency!

Yield: 8 oz. Prep time: 5 minutes Cook time: 25 minutes Total time: 30 minutes

Ingredients:

2 cups cranberries, fresh or frozen

1 cup water

1 cup white sugar

3 hop pellets, or flowers Instructions:

- In a small saucepan, add the cranberries, water, sugar, and your hop flowers. If you’re using hop pellets, be sure to grind with a grinder or mortar and pestle into a fine powder.

- Over medium-high heat, bring to a boil.

- Stir occasionally to dissolve the sugar.

- Reduce heat, cover, and simmer for 10 minutes.

- Turn off heat and allow the mixture steep for another 10 minutes.

- Place a bowl under a fine-mesh sieve, and strain the syrup.

- Store the hoppy cranberry simple syrup in an airtight container in the refrigerator. Enjoy for several weeks!

https://burrataandbubbles.com/spiced-cranberry-simple-syrup/

https://casualfoodist.com/easy-cranberry-simple-syrup/

Acknowledgements

This research was funded by Virginia Department of Agriculture and Consumer Services Specialty Crop Competitive Block Grant Program. The authors would also like to thank Mr. Randy Green from the Green Diamond Hopyard, LLC, and Mr. Justen Dick from Kelly Ridge Farms, LLC, for their support obtaining hop samples.

References

McGrory-Dixon, A. 2022. “Spiced Cranberry Simple Syrup.” Burrata Bubbles.

https://burrataandbubbles.com/spiced-cranberry-simple-syrup/

Brianna. 2021. “Easy Cranberry Simple Syrup.” Casual Foodist. https://casualfoodist.com/easy-cranberry-simple-syrup/

Garber, B., Morgan, K. L., Scoggins, H., and Seigle, L. 2019. “An Overview of Small-scale Commercial Hops Production in Virginia”. Journal of Food Distribution Research. 50(1): 98-92.

Lafontaine, S., Varnum, V., Roland, A., Delpech, S., Dagan, L., Vollmer, D., Kishimoto, T., and Shellhammer, T. 2019. “Impact of Harvest Maturity on the Aroma Characteristics and Chemistry of Cascade Hops Used for Dry-hopping.” Food Chemistry. 278: 228–239.

Perrine, M. 2019. “How to Make Hop Salt.” Craft Beering. https://www.craftbeering.com/how-to-make-hop-salt/

Perrine, M. 2021. “How to Make Hop Salted Caramel Sauce.” Craft Beering. https://www.craftbeering.com/hops-salted-caramel-sauce-diy-how-to-make/

Reineccius, G. 2005. “Chapter 3 Flavor Analysis, 3.2.6 Specific Analysis.” Flavor Chemistry and Technology. 58-63. Boca Raton, FL: CRC Press.

Reynolds, M. 2023. “Growing Hops in Virginia.” Wine and Country. https://wineandcountrylife.com/growing-hops/

Sharp, D. C., Townsend M. S., Qian, Y., and Shellhammer, T. H. 2014. “Effect of Harvest Maturity on the Chemical Composition of Cascade and Willamette Hops.” Journal of the American Society of Brewing Chemists. 72(4): 231-238.

Siegle, L., and Scoggins, H. 2019. “2018 Virginia Hop Grower Survey: Results.” VCE publication SPES- 131NP. https://www.pubs.ext.vt.edu/content/dam/pubs_ext_vt_edu/spes/spes-131/SPES-131NP.pdf

Steenackers, B., De Cooman, L., and De Vos, D. 2015. “Chemical Transformations of Characteristic Hop Secondary Metabolites in Relation to Beer Properties and the Brewing Process: A Review.” Food Chemistry. 172: 742-756.

Su, X. and Yin, Y. 2021. “Aroma Characterization of Regional Cascade and Chinook Hops (Humulus lupulus L.).” Food Chemistry. 364: 130410.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, national origin, political affiliation, race, religion, sexual orientation, genetic information, military status, or any other basis protected by law

Publication Date

November 1, 2023