Enhancing The Safety of Locally Grown Produce: Harvesting and Storage

ID

FST-42NP (FST-343NP)

Importance of safe food handling during harvest and storage

Harvest time means that fruits and vegetables will soon be on a consumer’s table. Consequently, it is critical to handle produce in a way that minimizes potential contamination with pathogens. It is important to follow some simple guidelines to prevent contamination and to control the growth of bacteria that might be present. The following steps can help to reduce risk of foodborne illness.

Steps to take prior to harvest

- When buying new equipment, be sure welds are smooth and surfaces are easy to clean and sanitize.

- When washing and sanitizing surfaces, use the appropriate cleaning and sanitizing agents (additional information follows).

- Wash tractors and trucks that have been used in areas of the farm that might have contacted raw manures or composts before going into the growing areas.

- Clean and sanitize packing and storage areas.

- Clean and sanitize harvesting tools such as knives, pruners, machetes, etc. and surface areas that will come in contact with produce.

- Use containers made of plastic that can be washed and sanitized between uses. Plastics labeled as “food grade” are ideal. If wood has to be used, it should be washed, sanitized and dried quickly and completely between uses.

- If cardboard boxes are to be used, the best practice is to purchase new, clean ones and only use them once. If boxes will be reused, they should be lined and the lining changed between uses.

- Train workers about the importance of thorough handwashing, use of toilet facilities and good personal hygiene.

- Provide handwashing facilities and post signs showing the steps of proper handwashing.

- Train workers to use gloves properly if they will be used during harvesting or packing. Gloves are not required for use by workers during harvesting. If they are used, disposable single use gloves are the best choice. Keep in mind when purchasing gloves that some workers may have a latex sensitivity. Teach workers when using gloves to:

• Wash hands prior to putting gloves on.

• Avoid touching hair, face, skin, etc. with gloves.

• Change gloves if they have been worn while eating, smoking, or using the bathroom; if they become soiled or torn and when changing tasks. - Take measures to keep birds and other pests out of packing and storage areas. (This may include the use of screens, doors, traps or physical deterrents.)

- Train workers to avoid harvesting dropped fruits or vegetables, produce from areas where animal feces is present and produce that shows signs of damage such as cuts or feeding marks.

- Establish an area for discarding produce waste that is located away from the harvesting and packing work areas and train workers on what to do with produce waste. Many farms compost produce waste. Follow scientific guidelines for composting to eliminate pathogens and to prevent contamination. (See Enhancing the Safety of Locally Grown Produce - Use of Manure and Other Soil Amendments of Animal Origin).

Steps to take during harvest

- Remind workers to wear clean clothes and footwear that has not been worn while working with animals and to avoid wearing rings and other jewelry.

- Exclude employees who have diarrhea, vomiting or nausea from working until they have been free of symptoms for 24 hours. Employees who have had jaundice should have a signed release from a doctor to return to work. Employees who have other illnesses such as a sore throat with fever should be reassigned to tasks that do not require handling produce or containers.

- Provide toilet facilities that are clean and well stocked and maintained no more than 1/4 mile walk from each worker in the fields and packing areas.

- Provide handwashing facilities that are no more than 1/4 mile walk from each worker in the fields and packing areas. Provide clean water that is free of detectable E. coli, liquid soap with pump dispensers and single use paper towels. Hand sanitizers may be provided for use in addition to handwashing but not to replace handwashing. (For more information on proper handwashing technique, see Enhancing the Safety of Locally Grown Produce: Farm Worker Hygiene.)

- Remind workers to wash hands after using the toilet, before and after eating and always before working with produce.

- Label growing plots, harvest bins and packaging in such a way that products can be traced. Keep records.

- Train workers not to harvest produce that has been contaminated with feces. For produce that grows off the ground, train workers not to harvest produce that has fallen to the ground.

Steps to take during postharvest handling

- Exclude pets, domestic animals and wild animals from the packing area.

- Clean and sanitize surfaces and equipment on a regular schedule – at least at the beginning and end of the day. Surfaces that will come in direct contact with fruits and vegetables will need more thorough and frequent cleaning and sanitizing than surfaces like walls or floors.

- Clean soil off of bins before leaving the field and do not place these bins on food contact surfaces.

- Get rid of standing water in produce handling areas.

- Use clean water free of detectable E. coli to rinse produce. Water temperature should be no more than 10˚F cooler than the produce being washed.

- Submerging produce that may be warm from the field in cold water may cause water to be sucked inside through openings such as stem scars of certain produce such as tomatoes, peppers, apples or potatoes. If pathogens are in the rinse water, then they will also be taken into the produce.

- Cool fruits and vegetables quickly to minimize growth of harmful bacteria and to preserve quality of the product. Proper storage temperatures will help maintain freshness and quality.

- Most fruits and vegetables can be stored at 41˚F. However, some produce may be susceptible to chilling injury. For a detailed list of storage conditions for specific whole fruits and vegetables, visit https://www.fcs.uga.edu/docs/Storage_of_Fresh_Produce.pdf. Cut fruits and vegetables must be kept at 41˚F or colder to be safe. Keeping produce like shelled peas, greens, etc. on ice or at 41˚F or colder will help maintain quality and safety.

- If ice is used for cooling, keep bins clean and use water that is free of detectable E. coli or, in other words, microbially safe to make ice. Use scoops and store them outside the ice bin so there is no bare hand contact with the ice.

- Use different boxes, bins or containers from the ones used in the field to pack the clean produce. Keep sets of containers separate from each other.

- Inspect storage areas daily to be sure sanitary conditions are met and temperature controls are working properly.

- Storage areas should be cleaned and sanitized regularly, at least weekly.

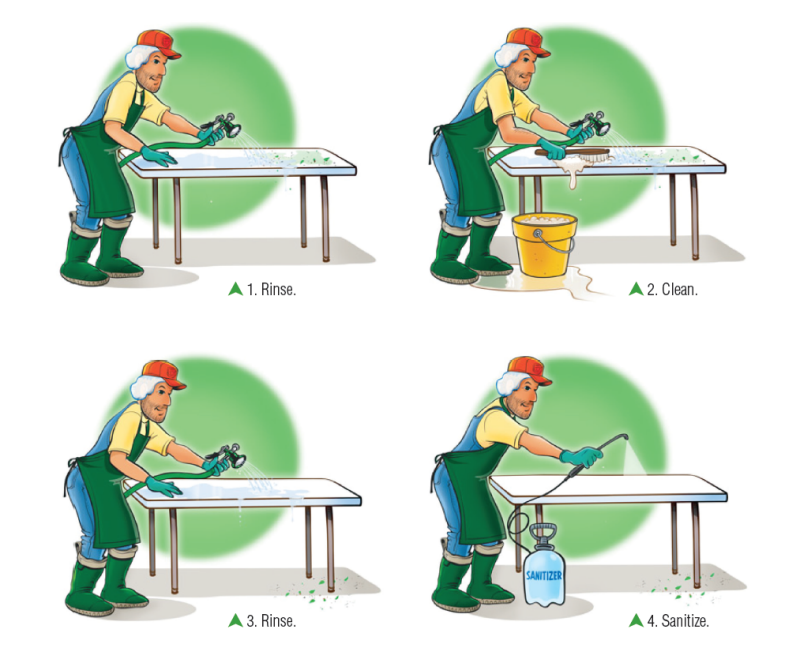

Cleaning and sanitizing

It is critical to clean and sanitize surfaces that come in contact with food. For sanitizing to be effective, cleaning must be done before sanitizers are used. Sanitizers are not as effective on dirty surfaces. The selection of cleaning and sanitizing agents can vary depending on the specific needs within a facility. Cleaning and sanitizing solutions should be made with clean water with no detectable generic E. coli. Keep in mind water hardness can also influence the effectiveness of cleaners. The following sequence should be followed: rinse, clean, rinse, sanitize.

- Cleaning: Detergents, such as dishwashing liquid, contain surfactants that reduce surface tensions between the soil and the surface so the soil is more easily removed. These agents may be used to clean most lightly soiled surfaces. If surfaces are more heavily soiled or if there is an accumulation of food residues that are difficult to clean, stronger cleaning agents like alkaline cleaners may be needed. If mineral deposits need to be removed, then acid cleaners may be needed. In some situations, mechanical force may be needed to efficiently clean surfaces.

- Sanitizing: Chemical sanitizers are used to reduce the number of microorganisms on surfaces to a level where they should pose no threat to public health. There are a number of sanitizing agents available for use in food handling areas after surfaces have been cleaned. Generally “broad-spectrum” sanitizers are used because they are effective against a wide range of microorganisms. A list of sanitizers, their common and chemical names and their EPA labeled uses can be found on the Produce Safety Alliance website in the resource list at https://producesafetyalliance.cornell.edu/resources/general-resource-listing.

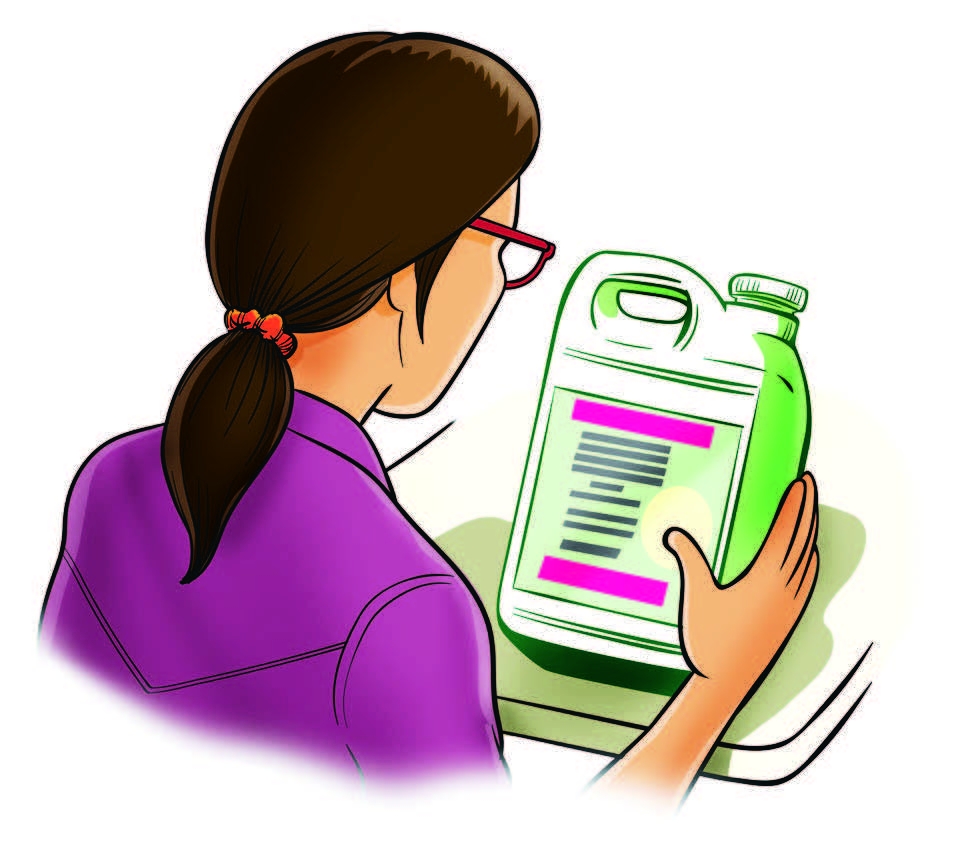

Any sanitizer used must have an EPA registration for a particular use. Label directions must be followed carefully. Some things to consider in choosing a sanitizer include the type of surfaces to be sanitized such as walls or floors (some sanitizers may be corrosive to stainless steel), water hardness, sanitizer application equipment that is available, effectiveness of the sanitizer on certain microorganisms, and the costs of the sanitizer and its application.

Sanitizers typically need a few minutes of contact time on the surface to be effective. Chlorine-based sanitizers are the most commonly used, are effective against a wide variety of microorganisms and are relatively inexpensive. To sanitize work surfaces and equipment that may come in contact with food, a solution of 200 parts per million of sodium hypochlorite is allowed by FDA. If plain, household chlorine bleach (5.6% sodium hypochlorite, such as EPA Reg. No. 5813-50), use 1 tablespoon bleach per gallon of water and allow a two minute contact time or air-dry. If concentrated bleach such as 8.5% sodium hypochlorite (EPA Reg. No. 5813-100), then use 2 teaspoons of bleach per gallon of water, and allow a two minute contact time or air-dry. To sanitize other surfaces that will not come in contact with food, a solution of 400 parts per million of sodium hypochlorite is allowed by FDA. These solutions should be made fresh at least daily. Use test strips to check sanitizer strength. Sanitizers can be applied as a wash, a dip, or a spray. For small areas, a hand pump sprayer can be used. There are maximum concentrations of sanitizers that can be legally applied to food contact surfaces. According to the National Organic Program, chlorine materials may be used up to maximum labeled rates for disinfecting and sanitizing food contact surfaces. Rinsing is not required unless mandated by the label use directions.

Follow this sequence to clean and sanitize surfaces.

Comparison of commonly used sanitizer types

| Chlorine | Iodophors | Quarternary ammonium compounds | Acid anionic | Peroxyacetic acid | |

|---|---|---|---|---|---|

| Corrosive | Corrosive | Slightly corrosive | Noncorrosive | Slightly corrosive | Slightly corrosive |

| Irritating to skin | Irritating | Not irritating | Not irritating | Slightly irritating | Not irritating |

| Effective at neutral pH | Yes | Depends on type | In most cases | No | Yes |

| Effective at acid pH | Yes, but unstable | Yes | In some cases | Yes, below 3.0-3.5 | Yes |

| Effective at alkaline pH | Yes, less than at neutral pH | No | In most cases | No | Less effective |

| Loss of effectiveness in presence organic material | Yes | Moderately | Moderately | Moderately | Partially |

| Loss of effectiveness in water hardness | No | Slightly | Yes | Slightly | Slightly |

| Residual antimicrobial activity | None | Moderate | Yes | Yes | None |

| Stability of use solution | Rapidly dissipates | Slowly dissipates | Stable | Stable | Slowly dissipates |

| Maximum level permitted by FDA on food contact surfaces without rinse | 200 ppm | 25 ppm | 00 ppm | Varied | 100-200 ppm |

To find cleaners and sanitizers most appropriate for your situation, contact a company that sells “food-grade cleaners” and “food-grade sanitizers” or check with a restaurant supply store.

This project was supported all, or in part, by a grant from the National Institute of Food and Agriculture, United States Department of Agriculture (Award Number 2009-51110-20161) and the Food Safety Outreach Program [grant no. 2016 0020-25888/project accession no. 1010671] from the USDA National Institute of Food and Agriculture.

Publication #FDNS-E-168-8, 2nd Edition. J.A. Harrison, M.A. Harrison, J.W. Gaskin, J. Cannon, R. Boyer, G. Zehnder and K. Woods.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. Cooperative Extension, the University of Georgia Colleges of Agricultural and Environmental Sciences and Family and Consumer Sciences, offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, gender or disability. An Equal Opportunity Employer/Affirmative Action Organization, Committed to a Diverse Work Force.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, genetic information, ethnicity or national origin, political affiliation, race, religion, sexual orientation, or military status, or any other basis protected by law.

Publication Date

January 15, 2025