Virginia Household Water Quality Program: Household Water Treatment

ID

442-670 (BSE-366P)

EXPERT REVIEWED

Private water sources such as wells and springs are not regulated by the U.S. Environmental Protection Agency (EPA). Although private well construction regulations exist in Virginia, private water supply owners are responsible for providing maintenance for their water systems, monitoring water quality, and taking the appropriate steps to address problems, should they arise.

The EPA public drinking water standards are good guidelines for assessing your water quality. “Primary drinking water standards” apply to contaminants that can adversely affect health and are legally enforceable for public water systems. “Secondary drinking water standards” are nonregulatory guidelines for contaminants that may cause nuisance problems such as bad taste, foul odor, or staining.

Testing your water annually and routinely inspecting and maintaining your water supply system will help keep your water safe. For more information, visit the Virginia Household Water Quality Program website at www.wellwater.bse.vt.edu.

Introduction

The U.S. Environmental Protection Agency regulates the allowable level of impurities in public water supplies, but homeowners that rely on private water systems, such as wells, springs, and cisterns, are solely responsible for the care and maintenance of their water supplies and for the quality of their water. Those with private water supplies can use the EPA drinking water standards as guidelines when assessing their water quality. When levels of selected impurities in household water exceed EPA guidelines, they may affect human health or they may be a nuisance, possibly affecting the taste, smell, or appearance of the water.

Water is often called the universal solvent. As water moves under ground or over land, it dissolves a variety of compounds, including minerals, salts, and organic compounds. Under certain circumstances, water can dissolve metals in household plumbing systems, adding impurities to the water. Impurities may also come from human activities (e.g., misapplying fertilizers or pesticides), and water can also contain microbiological organisms.

This publication discusses several types of water treatment devices and, in general terms, the mechanism each device uses to treat water. No single water treatment device treats all problems, and all devices have limitations. Once installed, periodic testing of water samples collected before and after a water treatment device is recommended to ensure the device is working as intended. A table included at the end of this publication provides a summary of the common water treatment devices discussed in this publication, their primary use, and the maintenance and limitations associated with each device.

The remainder of this publication provides an overview of common water treatment devices used in the home.

Filtration: activated carbon filter, sediment filters, media filters, and oxidizing filters.

Acid water neutralizing filter.

Water softeners.

Reverse osmosis.

Disinfection methods: boiling water, continuous chlorination, and ultraviolet disinfection.

Distillation.

Filtration

Activated Carbon Filters

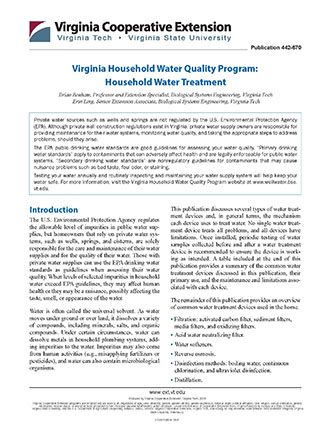

Activated carbon filters can be used to treat general taste and odor problems through the removal of chlorine, some organic compounds (such as some pesticide residues), radon, and some heavy metals, like lead — if they are specifically designed to do so. Impurities are adsorbed, or bound, to the activated carbon as water flows through the filter (fig. 1).

The effectiveness of an activated carbon filter device depends on the design of the filter, the type and concentration of the impurities, and the amount of time the water is in contact with the activated carbon media. To function properly, these filters must be changed according to the manufacturer’s recommendation. Activated carbon filters are typically point-of-use (POU) devices, such as a faucet-mounted filter or pour-through drip units. Higher capacity point-of-entry (POE) activated carbon filters are typically only recommend for cases where volatile organic compounds, radon, or other impurities should be removed before water enters the house.

Sediment Filters

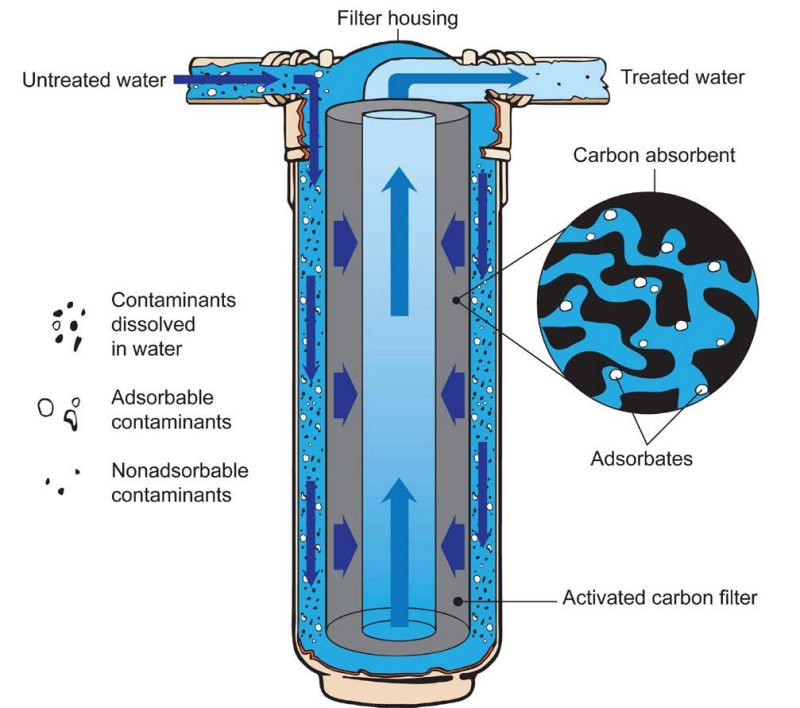

Sediment filters are typically used to remove suspended particles found in water (e.g., sand, silt, clay, and oxidized iron and manganese). Sediment filters remove impurities by passing the water through a filter material that is rated or sized according to the smallest particle it can trap (e.g., 20 microns; a micron is one-millionth of a meter).

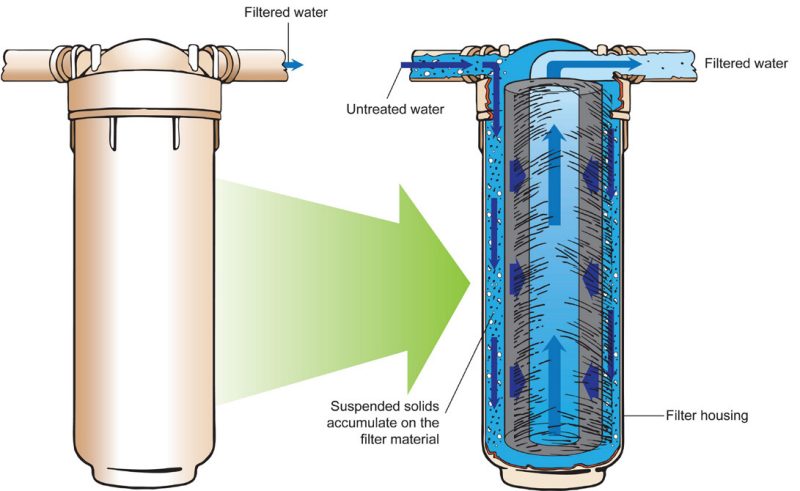

Cartridge-type filters (fig. 2) are often used in household applications. Typical cartridge filter media types include pleated paper, cellulose, wound string, and spun polypropylene (fig. 3).

Maintenance involves periodically changing filter cartridges. Sediment filters can be sized and installed to treat water at the POU, such as a kitchen tap or refrigerator, or higher capacity POE devices can treat all water entering the house.

Media Filters

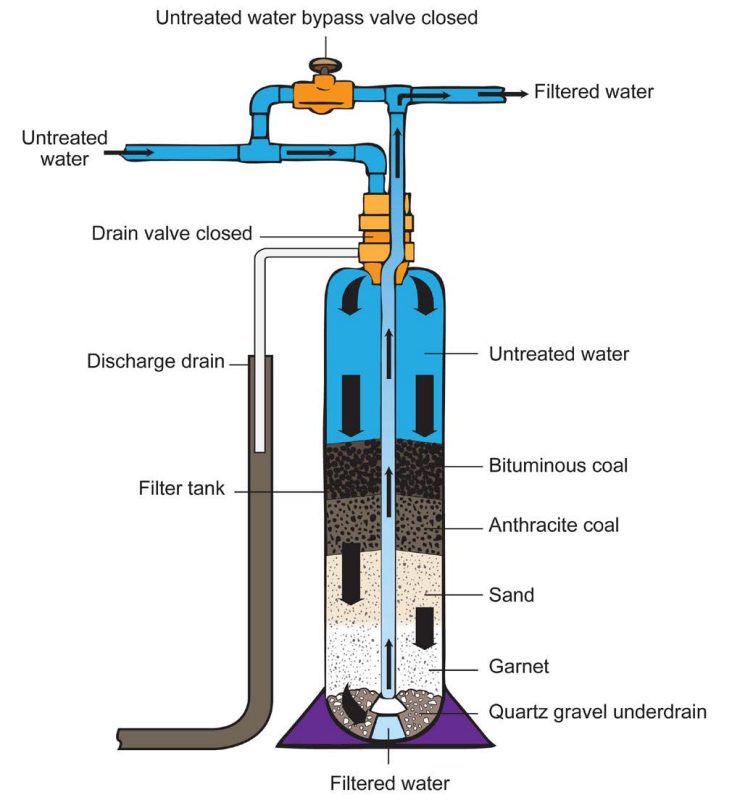

Media filters (fig. 4) use a graded, coarse (garnet) -to- fine (bituminous coal) media to trap suspended particles. In some situations, multiple filters may be needed to remove suspended particles from the water, with each subsequent filter trapping smaller and smaller particles.

Maintenance involves periodic backwashing to clean and refresh the filter media. Depending on the unit, backwashing may be automatic or manually activated. Media filters are typically POE devices that treat all water entering the house.

Oxidizing Filter

Occasionally, impurities must be converted into another form to be removed more easily. An oxidizing filter is a POE treatment device that converts dissolved iron, manganese, or hydrogen sulfide (the gas that produces the rotten egg odor) into a solid form and then filters the solid particles from water. The device looks similar to a media filter or water softener, but the media in the oxidizing filter is typically a manganese-treated greensand. Other filter media are available depending on the application.

Maintenance typically involves periodically recharging the greensand media with an oxidizing agent (typically potassium permanganate) and backwashing. The potassium permanganate forms a coating that reacts with the dissolved iron, manganese, or hydrogen sulfide to form solid particles that are then trapped in the filter media. The backwashing and recharging frequency depend on the type and amount of impurities in the water and the volume of water being treated.

Acid Water Neutralizing Filter

The acidity or alkalinity of water is measured using the pH scale, which ranges from 1.0 to 14.0. A pH value of 7.0 is neutral, less than 7.0 is acidic, and greater than 7.0 is basic, or alkaline. The EPA-recommended pH range for public drinking water supplies is between 6.5 and 8.5. While consuming acidic water in itself is not a health hazard, water that is acidic can be corrosive and can dissolve metals present in household plumbing — most commonly copper and lead. Consuming dissolved lead and copper in drinking water can be a health hazard. Some dissolved metals can also cause nuisance problems, such as staining of plumbing fixtures or causing water to have a bitter or metallic taste.

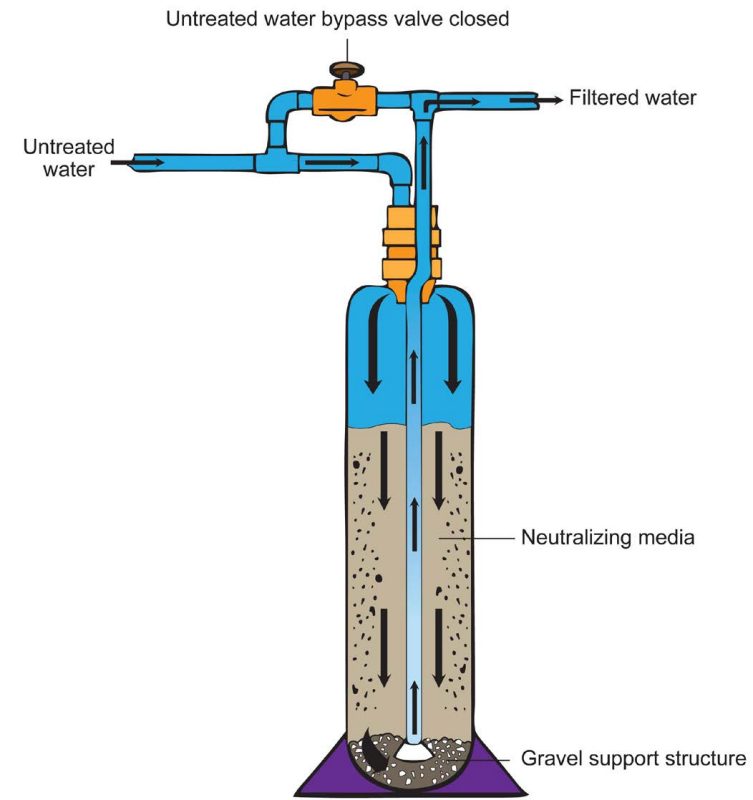

An acid water neutralizing filter is a relatively simple treatment device that raises the pH of water by adding a neutralizing material, which decreases the likelihood that the water will dissolve metal pipes and fixtures. The most common type of neutralizing filter is the tank type, in which water flows through a neutralizing media composed of calcium carbonate (limestone), crushed oyster shells, marble chips, or synthetic magnesium oxide material (fig. 5). As the water flows through the neutralizing media, the media is dissolved and the pH of the water increases.

Maintenance involves periodically adding more neutralizing media. How frequently the media must be replenished depends on the pH and the volume of water being treated. Using an acid water neutralizing filter will likely increase the hardness of the water. Depending on the amount of hardness added, a water softener may also be needed. Acid water neutralizing filters are typically POE devices that treat all of the water entering the house.

Water Softeners

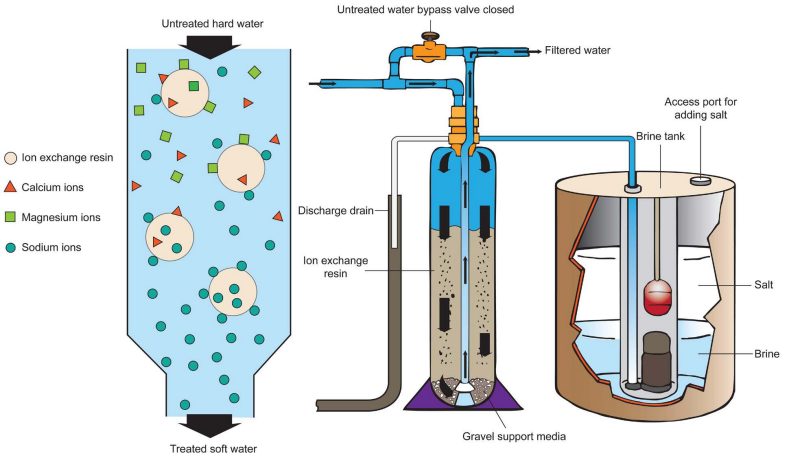

“Hard” water is water with high levels of minerals (calcium and magnesium) that it acquires as it flows through and dissolves natural geologic deposits — usually limestone or other carbonate rock. The most common way to remove hardness, or to “soften” household water, is a cation-exchange water softener. Water exceeding about 7 to 8 grains per gallon (gpg) or approximately 120 milligrams per liter (mg/L) of hardness may interfere with the cleaning action of soaps and detergents and may cause mineral deposits (scale) on dishes, appliances, and plumbing fixtures.

Cation-exchange water softeners work by replacing hard water ions (calcium and magnesium, which are positively charged ions, or cations) with soft ions (sodium, also positively charged). This ion exchange occurs as water flows through the ion-exchange resin, which is stored in the softener tank (the center tank in fig. 6).

Water softener maintenance involves routinely adding sodium pellets to a brine tank typically located adjacent to the softener tank (fig. 6). These pellets typically come in 40-pound bags. The brine solution is used to periodically regenerate the ion-exchange resin by adding sodium cations. Resin regeneration may be automatic, semiautomatic, or manual — depending on the system. The most efficient water softeners use a flowmeter to determine regeneration cycle frequency. Some water treatment companies offer maintenance programs for water treatment devices, including softeners.

POE water softener devices can be installed to treat all water used in the house or only the water that flows to the hot water heater. Water used for drinking, cooking, toilets, and outdoor use should not normally be softened. Water softeners can also be used to remove small amounts of iron and manganese (with combined concentrations less than 5 mg/L).

If a water softener is being used to remove iron, all water entering the house should be treated. Because water softeners are designed to meet specific needs, it is critical to have a water sample analyzed by a certified lab before purchasing any water treatment device.

Water softeners add sodium (salt) to water. Individuals on restricted-sodium diets should consult a physician before consuming softened water.

Reverse Osmosis

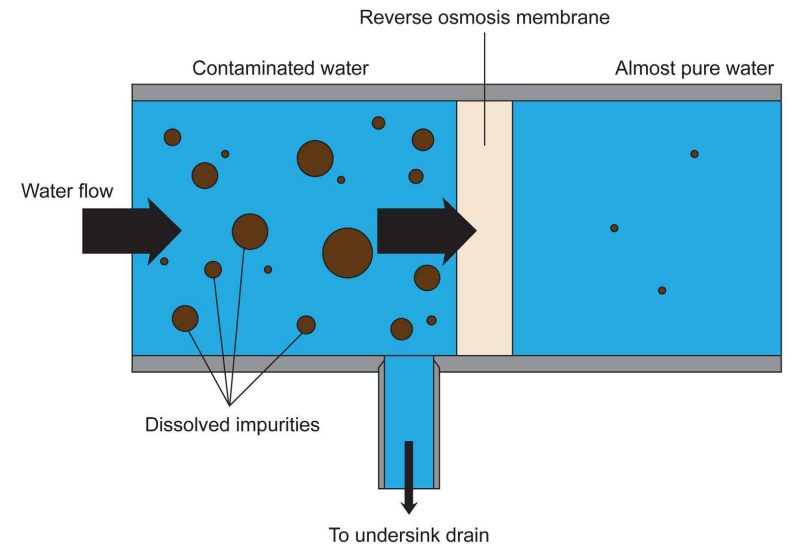

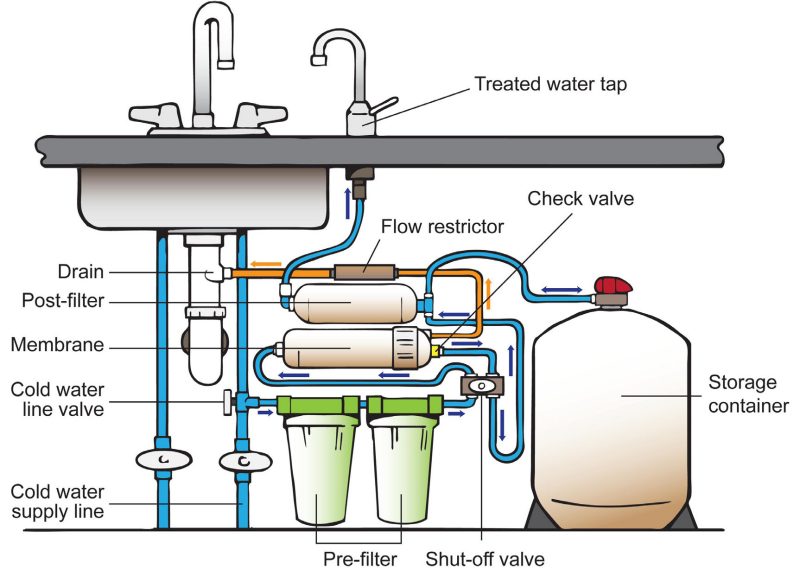

Reverse osmosis (RO) units are typically POU devices capable of reducing the concentration of most dissolved and suspended inorganic impurities, but they are not typically recommended to remove organic impurities, including bacteria. With RO systems (fig. 7), impurities are removed as water is forced through a semipermeable membrane with microscopic holes that are large enough to allow water molecules to pass through but small enough to block most dissolved and suspended impurities. Ten to 20 percent of the water entering the RO system exits as treated water. The other 80 to 90 percent is wastewater that is diverted to a drain.

Care must be taken not to foul (clog) the RO membrane. Hard water can quickly foul an RO membrane. A sediment prefilter is frequently used to pretreat the water before it enters the RO membrane unit. An activated carbon postfilter may be used after the RO membrane unit (fig. 8). In some modular RO systems, these components may be included in a single unit.

Maintenance involves periodically replacing the RO membrane and any associated filters in accordance with the manufacturer’s recommendations.

Disinfection Methods

Boiling Water

Various types of disinfection methods can be used to treat microbiologically unsafe water. Perhaps the most straightforward disinfection method is boiling. Disinfection via boiling requires a vigorous or roiling boil for at least one minute. While boiling water is an effective disinfection method for small quantities of water, boiling is not an efficient means of disinfecting water for use in an entire house. Typical POE disinfection methods for household water disinfection include continuous chlorination and ultraviolet (UV) radiation.

Continuous Chlorination

Continuous chlorination systems use a chemical meter to add chlorine to the water supply system to kill bacteria. With a sufficiently high chlorine concentration and adequate contact time, chlorine will kill bacteria and certain viruses, but it will not kill Giardia or Cryptosporidium — two parasites associated with surface water contamination of wells and springs.

The effectiveness of chlorine depends on the concentration of chlorine in the water, the amount of time the chlorine is in contact with the water prior to use (contact time), the water temperature, the pH of the water, and the characteristics of other impurities in addition to the amount of bacteria in the water supply. Because the groundwater may contain several impurities that can be oxidized by the addition of chlorine (e.g., organic matter other than the bacteria, dissolved metals such as iron and manganese, or hydrogen sulfide), the amount of chlorine needed to treat a given water supply must be determined on a case-by-case basis. A sediment or media filter may be required following a chlorination system to filter out oxidized impurities. If chlorine taste or odor is an issue, an activated carbon filter may be needed to remove residual chlorine from the treated water.

Maintenance of continuous chlorination systems involves ensuring that the metering device is feeding the correct amount of chlorine to the system and ensuring that there is a sufficient supply of chlorine (solution, powder, or tablets) available. Closely following the manufacturer’s operating instructions is critical to ensuring that continuous chlorination devices function properly.

Ultraviolet Radiation

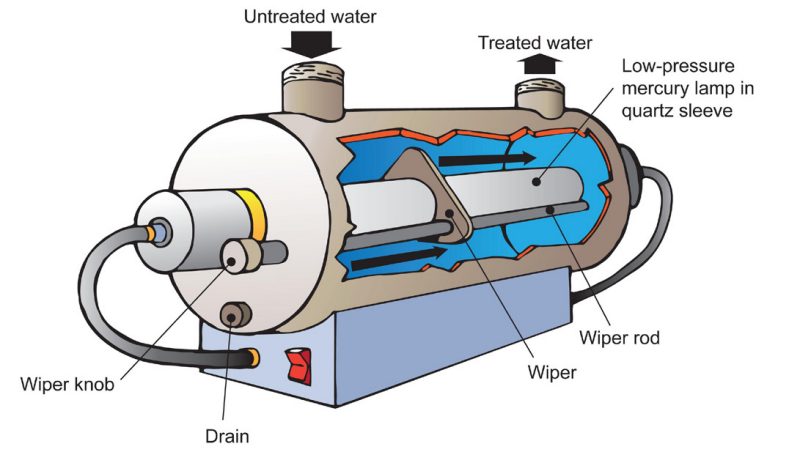

Using ultraviolet radiation for continuous disinfection is fairly common. UV radiation disrupts the bacteria’s genetic material, making reproduction impossible. While UV radiation is effective for bacteria and viruses, it is less effective for Giardia or Cryptosporidium. In a typical household UV system, untreated water enters the UV unit and is exposed to the UV radiation as it flows through the device (fig. 9).

To effectively disinfect a water supply, the UV lamp must emit UV light at the correct intensity. The age of the lamp and the characteristics of the water being treated both affect intensity. UV lamps weaken over time and must be changed according to the manufacturer’s recommendations.

Water that is cloudy or contains sediment will limit UV light penetration. As a result, the UV disinfection system is typically the last device in a household water treatment system, preceded by other devices designed to filter or otherwise clarify the water supply. To ensure effective light penetration, the housing containing the

UV lamp must also be kept clean. Some units have integrated wipers that are used to periodically clean the quartz sleeve that houses the UV lamp (fig. 9).

Finally, the concentration of bacteria in the water supply can also affect UV radiation treatment effectiveness. If the water supply contains large concentrations of bacteria (more than 1,000 total coliforms per 100 milliliters or more than 100 fecal coliforms per 100 milliliters), an alternative disinfection method is recommended.

Distillation

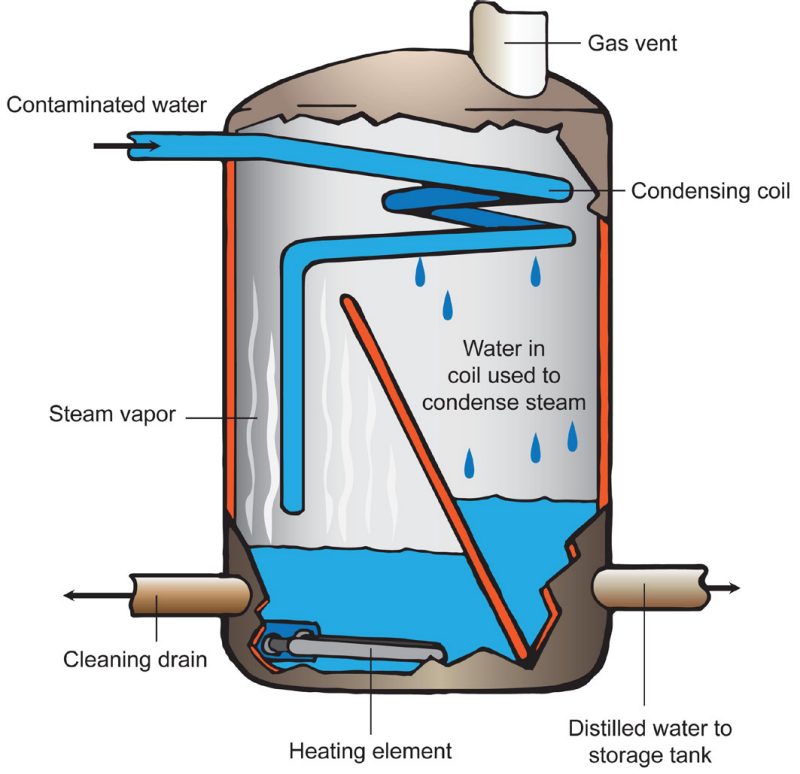

Distillation is perhaps the oldest form of water treatment. Distillation units boil water to create steam, which is then condensed and collected as distilled water (fig. 10). Distillation reduces the concentration of metals, minerals, and some organic chemicals. Impurities remain in the evaporation chamber (where the heating element is located). Because distillation removes minerals that are naturally present in water that impart taste, distilled water can have a very “flat” taste.

Some distillation units may allow undesirable impurities that have a boiling point lower than water (e.g., some pesticides and volatile solvents) to vaporize and recondense, which means they remain in the distilled water. Some distillation units have a volatile gas vent that releases these impurities into the atmosphere. Distillation also works to disinfect water by killing micro- organisms and bacteria.

Distillation units are typically POU devices that treat comparatively small volumes of water. Countertop units typically yield less than 3 to 4 gallons of water per day. Larger units can yield 8 to 12 gallons per day. Home distillation units tend to be energy intensive, requiring about 800 watts of electricity to distill 1 quart of water.

Periodic maintenance and cleaning of the distillation unit is required because minerals and other impurities accumulate in the evaporation chamber and can potentially interfere with the operation. Hard water can be especially problematic with distillation units because a mineral scale can form in the evaporation chamber and on the heating element, increasing operating costs. As with any treatment device, follow the manufacturer’s maintenance recommendations.

Summary

It is critical to have a water sample analyzed by an independent, certified lab and to consult a professional before purchasing any water treatment equipment. Keep in mind that no single water treatment device treats all problems, and all devices have limitations.

In many cases, there are multiple household water quality issues that must be addressed. In these situations, a combination or system of treatment devices may be needed. The water treatment system designer must consider the type and concentration of the various impurities to be removed and the intended use for the treated water (e.g., drinking and cooking versus laundry, bathing, or flushing toilets). The initial cost as well as the operating costs must be considered when selecting water treatment equipment.

One should also be aware of the type and amount of maintenance needed to ensure the equipment functions properly. Consider getting two or three opinions from different suppliers before making a decision to purchase a water treatment device or system.

Finally, any water treatment equipment being considered should be certified by an independent third party, like NSF International (www.nsf.org). All water treatment devices must be properly maintained to work as intended. Periodic water quality testing of samples collected before (upstream) and after (downstream) any water treatment device is recommended to ensure it is working properly.

Additional Information

Remember, the manufacturer’s manual is the best resource for maintenance instructions for your water treatment device. For additional information on water quality and treatment, contact your local Virginia Cooperative Extension office.

For more drinking water quality information, see these Virginia Cooperative Extension websites:

Virginia Household Water Quality Program – www.wellwater.bse.vt.edu/resources.php

Virginia Cooperative Extension – http://pubs.ext.vt.edu/category/home-water-quality.html

| Device | Primary use | Maintenance and limitations |

|---|---|---|

| Activated carbon filter | Removes chlorine and some organics. Used to address general taste and odor issues. Can be used to remove some metals if designed to do so. | Does not remove bacteria or nitrate. Requires periodic replacement of activated carbon media. |

| Sediment filter | Removes suspended particles that cause turbidity (e.g., sand, silt, clay, oxidized iron, manganese, and sulfur). | Requires periodic cartridge replacement. |

| Media filter | Removes suspended particles that cause turbidity (e.g., sand, silt, clay, oxidized iron, manganese, and sulfur). | Requires periodic backwashing to clean and refresh the media. |

| Oxidizing filter | Filters out oxidized iron, manganese, and hydrogen sulfide. | Requires periodic backwashing and regeneration of filter media. |

| Acid water neutralizing filter | Raises pH, reducing water corrosiveness. | May increase water hardness. Requires periodic addition of neutralizing media. |

| Water softener | Reduces water hardness, removing dissolved calcium and magnesium. Improves cleaning action of soaps, etc. Prevents scale deposits in pipes and appliances. | Requires periodic addition of salt to brine tank. Requires periodic backwashing and regeneration of softener resin. |

| Reverse osmosis | Reduces the concentration of dissolved and suspended impurities in water. | Typically yields 10-20% treated water by volume. Requires storage for treated water. Hard water can foul RO membrane. Must periodically replace RO membrane and any associated filters. |

| Continuous chlorination | Disinfects water supply by adding chlorine. | Must ensure sufficient chlorine concentration and contact time to achieve disinfection. Must maintain chlorine supply and ensure chlorine-metering device is working properly. Sediment and activated carbon filters may be required. |

| UV disinfection | Disinfects water supply by exposing bacteria to UV radiation. | May require sediment filter upstream of UV unit to reduce turbidity. Must periodically replace UV bulb. |

| Distillation | Removes most impurities and disinfects by boiling water, then condensing steam. | Yields limited volume of treated water. May be expensive to operate due to energy cost. Treated water may have “flat” taste. Hard water can interfere with operation. |

Acknowledgments

This publication was adapted from “Household Water Treatment,” Virginia Cooperative Extension publication 356-481, by K. Parrott, B. Ross, and J. Woodard, 1999. The authors wish to thank the following individuals who reviewed this publication: Sharon Skipton, extension water quality educator, Nebraska Cooperative Extension; Renee Boyer, food science and technology specialist, Virginia Cooperative Extension; John Thompson, agriculture and natural resources agent, VCE Fluvanna County Office; and Dawn Barnes, family and consumer sciences agent, VCE Floyd County Office.

References

Clemens, Stephanie, and Bryan Swistock. 2007. Water Facts No. 18: Tips for Buying Water Treatment Equipment. Penn State. College of Agricultural Sciences, Cooperative Extension. School of Forest Resources. Code XH0022.

Connecticut Department of Health. 2009. Publication No. 19: Questions to Ask When Purchasing Water Treatment Equipment for Your Home. Environmental Health Section, Private Well Program. Private Drinking Water in Connecticut Series. Connecticut Department of Public Health.

Dvorak , B. and B. Schuerman. 2021. Drinking Water: Iron and Manganese G1714. Retrieved online: https://extensionpubs.unl.edu/publication/g1714/2021/pdf/view/g1714-2021.pdf.

Midwest Plan Service. 1992. Private Water Systems Handbook. Iowa State University. MWPS-14. Ames, Iowa.

PlumbingSupply.com. 1995. “Acid Neutralizer Installation Information.” Web page https://www.plumbingsupply.com/neutralinstall.html.

Wagenet, L., K. Mancl, and M. Sailus. 1995. Home Water Treatment. Natural Resource, Agriculture, and Engineering Service. Cornell University Cooperative Extension. Publication NRAES-48.

The Virginia Household Water Quality Program, offered through Virginia Cooperative Extension, periodically conducts county-based household water sampling clinics where you can learn about the quality of your water supply, proper water supply system maintenance, and, if needed, possible water treatment options. Please contact your local Extension office or visit

www.wellwater.bse.vt.edu for more information.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

October 22, 2024