Assessing On-Farm Produce Safety Risks: General Practices

ID

FST-401NP

Overview

As consumption of fresh fruits and vegetables in the United States has increased, so have foodborne disease outbreaks and recalls associated with fresh produce (Callejón 2015; Painter 2013). In addition to compliance with regulations such as the Food Safety Modernization Act (FSMA) Produce Safety Rule, the marketplace has become stiffer in terms of on-farm produce safety requirements. Growers selling to larger buyer channels and institutions are often required to obtain Good Agricultural Practices (GAP) food safety certification. While growers selling through direct market channels including farmers markets and roadside stands do not typically need certification, they may have on-farm produce safety standards to achieve. Regardless of the market outlet channel and/or size of the farm, the potential for produce contamination exists. Thus, understanding on-farm produce safety risks is essential for all farms who grow, harvest, pack, hold and/or ship fruits and vegetables.

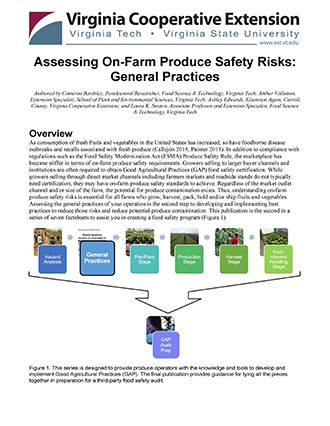

Assessing the general practices of your operation is the second step to developing and implementing best practices to reduce those risks and reduce potential produce contamination. This publication is the second in a series of seven factsheets to assist you in creating a food safety program (Figure 1).

Figure 1. This series is designed to provide produce operators with the knowledge and tools to develop and implement Good Agricultural Practices (GAP). The final publication provides guidance for tying all the pieces together in preparation for a third-party food safety audit.

General Practices

Employees (full-time and part-time) are essential to maintaining food safety standards and reducing potential contamination risks. For example, employees may handle (touch) produce; therefore, their commitment to food safety is critical to minimize contamination risks by following hand-washing practices or alerting a supervisor if they are sick. Policies and practices should be implemented on the farm to ensure that employees understand the farm’s food safety program and what is expected of them. For example, a farm should have a policy on proper toilet and handwashing practices that may include how to use the toilet and dispose of toilet paper, as well as how to effectively wash hands (e.g., scrubbing for 20 seconds, using potable water). Farms should also use signage and hold annual (or more frequent) trainings to guide employees in performing various worker health and hygiene policies and practices.

Health and Hygiene

Employees may come in contact with fresh produce at multiple places along the supply chain, especially on the farm during various growing and harvesting activities. An employee’s health and hygiene practices directly influence the safety of fruits and vegetables. All employees and visitors must follow health and hygiene practices to minimize the risk of contamination by human pathogens. For example, employees with a diarrheal disease, open lesions, and/or other illnesses are prohibited from any task where the employee would come in contact with the product, until the condition has resolved. If cuts, abrasions, and/or other injuries occur, employees must alert their supervisors and receive treatment (e.g., farms should provide a first aid kit). Farms should have a policy that specifies the handling and removal of produce and/or food contact surfaces that come into contact with blood or other bodily fluids. Eating, chewing gum, tobacco use, and drinking (not including water in a non-glass container) should not occur in growing, packing, and storage areas. Farms should designate areas for smoking and eating that are away or separate from where fruits and vegetables are grown, handled, and/or packed. Employees who handle (touch) produce must wash their hands before starting or returning to work, as well as after eating, smoking, or after any instance where hands may get dirty. Additionally, drinking water and handwashing stations must use water that meets the microbial standards for the U.S. Environmental Protection Agency (EPA) drinking water standards (U.S. EPA 2009).

Required signage (e.g., rules for visitors, bathroom and handwashing stations, designated break areas, drinking water vessels, chemical storage, first aid kit locations, traceability system coding, areas that are off limits, etc.,) should be posted to instruct or remind employees and any visitors of the farm’s food safety practices or show them where important items or facilities are located (Figure 2). When developing employee signage, signage should be easily understandable in a language all employees can understand and should use pictures or graphics for those who may not be able to read. Signage should always be posted in a visible location in which other materials aren’t distracting.

Figure 2. Effective signage will remind and inform employees and visitors of food safety practices on the farm. Signs should be easily understood and placed in locations that are easily visible.

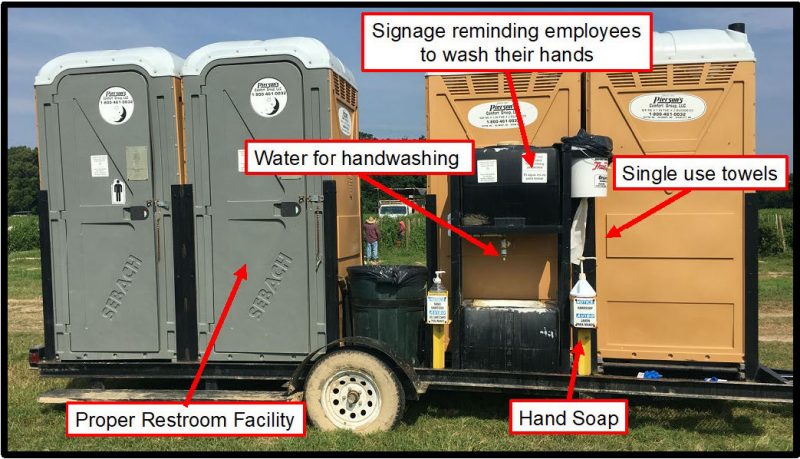

Toilet and handwashing stations must be available for employee and visitor use. These toilet facilities should be located within at least a ¼ mile of work areas, and should not be located too close to where produce is grown, harvested, and stored to avoid spillage or leakage events where product could become contaminated (i.e. uphill from fields and storage areas). Toilet and handwashing stations must be supplied with single use towels, hand soap, toilet paper, potable water for handwashing, and a catch basin for greywater (Figure 3). The presence and availability of these materials should be monitored and well stocked. All toilet and handwashing stations must be serviced and cleaned on a scheduled basis, which is based on size of farm and/or number of employees and frequency of visitors. Records on the maintenance, cleaning, stocking, etc., of toilet and handwashing stations should be kept.

Figure 3. Clean restroom facilities, water for handwashing, hand soap, and single use towels must be available for employees and located near working areas that are easily accessible.

Training

The most effective training occurs when the supervisor/employer adheres to the rules and demonstrates unflagging commitment to the developed food safety program. Employees should be trained at least annually each year, with additional trainings when policies or practices change or unexpected events happen. Furthermore, employees should be retrained if they violate specific food safety policies or practices. At a minimum, all employees should be trained on food safety policies and practices that pertain to their role on the farm. Trainings should be presented in a language that workers can understand or use visual aids. Remember, records of training should be kept including: topics covered, the date, trainer name, employee names, and any other supporting documentation (e.g., handouts, certificates, etc.).

On-Farm Produce Safety General Questions Checklist

Use the list of items below as a guide to tasks that should be completed as part of your on-farm food safety program. Once each task is conducted, check off that item. For items that do not apply to your operation, write N/A next to the item.

Consider and develop written employee health and hygiene policies and practices related to produce handling for all stages of your operation.

Determine specific training materials and resources needed for educating all employees in

understanding risks and best food safety practices.

Make sure any training materials are in appropriate languages and format for ease of understanding.

Develop written rules related to expectations for visitors and other non-farm persons.

Think through your restroom/portable toilet and handwashing station facilities set-up.

Consider accessibility to employees, rental costs, water availability, maintenance schedules, and corrective action measures in regards to restrooms/toilet and handwashing stations.

Construct and/or rent restroom/toilet facilities as needed.

Designate eating, drinking, and smoking break areas.

Determine how drinking water will be provided to employees. If using a cooler, consider the water source and cleaning schedule for the cooler.

Establish illness and injury protocols, as well as buy/stock first aid kits.

Determine where first aid kits will be kept for quick access, i.e. trucks, pack areas, etc.

Purchase/create, and post understandable signage in pertinent locations to remind employees and visitors of food safety practices and policies.

Decide how (clipboard log, notebook, phone app) and where food safety procedures and practices will be documented, as a part of your overall recordkeeping system.

Create a system that works best for you and your employees, is readily accessible, and is not unwieldy to maintain.

- Name

- Signature

- Date

References

Callejón, R. M., M.I. Rodríguez-Naranjo, C. Ubeda, R. Hornedo-Ortega, M.C. Garcia-Parrilla, and A.M. Troncoso. 2015. Reported Foodborne Outbreaks due to Fresh Produce in the United States and European Union: Trends and Causes. Foodborne Pathogens and Disease. 12, 32–38. doi:10.1089/fpd.2014.1821.

Painter, J. A., R.M., Hoekstra, T. Ayers, R.V. Tauxe, C.R. Braden, F.J. Angulo, et al. 2013. Attribution of Foodborne Illnesses, Hospitalizations, and Deaths to Food Commodities by Using Outbreak Data, United States, 1998–2008. Emerging Infectious Diseases. 19, 407–415. doi:10.3201/eid1903.111866.

U.S. Environmental Protection Agency. 2009. National Primary Drinking Water Regulations. Accessed: July 7, 2020.

Additional Resources

Bardsley, C., A. Vallotton, A. Edwards, and L.K. Strawn. 2021a. Assessing On-Farm Food Safety Risks: Performing a Hazard Analysis. Virginia Cooperative Extension.

Bardsley, C., A. Vallotton, A. Edwards, and L.K. Strawn. 2021c. Assessing On-Farm Food Safety Risks: Pre- Plant Stage. Virginia Cooperative Extension.

Bihn, E.A., M.A. Schermann, A.L. Wszelaki, G.L. Wall, and S.K. Amundson. 2014. On-Farm Decision Tree Project: Worker Health, Hygiene, and Training.

Edwards, A., A. Vallotton, C. Bardsley, and L.K. Strawn. 2021. Assessing On-Farm Food Safety Risks: Preparing for GAP Certification. Virginia Cooperative Extension.

Produce Safety Alliance. 2019. Module 3, Worker Health, Hygiene, and Training, v.1.2. Cornell University.

Vallotton, A., Bardsley, C., A. Edwards, and L.K. Strawn. 2021a. Assessing On-Farm Food Safety Risks: Production Stage. Virginia Cooperative Extension.

Vallotton, A., Bardsley, C., A. Edwards, and L.K. Strawn. 2021b. Assessing On-Farm Food Safety Risks: Harvest Stage. Virginia Cooperative Extension.

Vallotton, A., Bardsley, C., A. Edwards, and L.K. Strawn. 2021c. Assessing On-Farm Food Safety Risks: Post- Harvest Handling Stage. Virginia Cooperative Extension.

Vallotton, A., S. Gugercin, L. Strawn, R. Boyer, and M. Chase. 2018. Virginia Fresh Produce Food Safety.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

January 20, 2022