Assessing On-Farm Produce Safety Risks: Harvest Stage

ID

FST-404NP

Overview

As consumption of fresh fruits and vegetables in the United States has increased, so have foodborne disease outbreaks and recalls associated with fresh produce (Callejón 2015; Painter 2013). In addition to compliance with regulations such as the Food Safety Modernization Act (FSMA) Produce Safety Rule, the marketplace has become stiffer in terms of on-farm produce safety requirements. Growers selling to larger buyer channels and institutions are often required to obtain Good Agricultural Practices (GAP) food safety certification. While growers selling through direct market channels including farmers markets and roadside stands do not typically need certification, they may have on-farm produce safety standards to achieve. Regardless of the market outlet channel and/or size of the farm, the potential for produce contamination exists. Thus, understanding on-farm produce safety risks is essential for all farms who grow, harvest, pack, hold and/or ship fruits and vegetables.

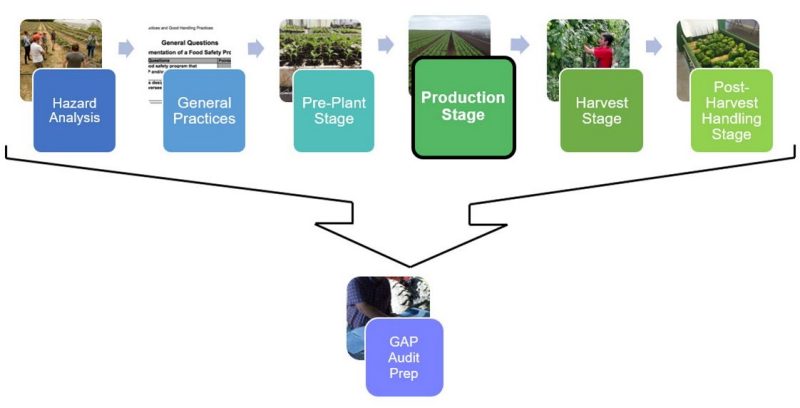

Identifying risks that may be associated on your farm during the harvest stage is the fifth step to developing and implementing best practices to reduce those risks and reduce potential produce contamination. This publication is the fifth in a series of six publications to assist you in creating a food safety program (Figure 1).

Figure 1. This series is designed to provide produce operators with the knowledge and tools to develop and implement Good Agricultural Practices (GAP). The final publication provides guidance for tying all the pieces together in preparation for a third-party food safety audit.

Harvest Processes

The harvest stage involves any processes taken just before, during, and immediately following the mechanical and/or hand picking and gathering of a mature crop. It is important to consider the entire harvesting process so risks can be minimized (Figure 2). Some questions to ask are:

What specific harvest methods will be used?

Mechanical machinery

Hand digging, jerking, picking, or hand tools for cutting and clipping

Combination of equipment and hand harvesting

What specific tools and equipment are needed?

Knives, machetes, shears, scissors

Specialized harvesting machines

Digging forks or mechanical diggers

Ladders, buckets

Where will product be placed immediately after harvest?

Harvest picking containers, totes, bins, or bulk containers

Cardboard boxes

Clamshells

Does the harvested produce need special handling in the field or protected culture area to maintain quality?

Ice

Coolers

Refrigerated vehicle

How will harvested produce be moved within and from the field or production area?

Wagons, trailers, pick-up truck, refrigerated truck

Figure 2. Various aspects of the harvesting process to consider.

Conducting a Pre-harvest Assessment

Before fresh produce is harvested, a pre-harvest assessment should always be conducted on the production areas. The pre-harvest assessment should identify any potential sources of crop contamination, and then survey any potential “signs” of contamination (e.g., animal droppings). Primarily, this approach incorporates a visual observation of production areas (like scouting for pests). Evidence of animal intrusion could include animal feces on crops or in between crop rows, animal tracks, trampled or partially eaten crops, rodent tunnels or soil mounds, and damaged drip lines. Similarly, in protected culture production systems, signs of intrusion could be droppings, disturbance (e.g., shredding, debris) of stored items, and digging in corners or against walls.

Another part of the pre-harvest assessment includes weather events. A storm causing a flash flood that runs off and does not cause water to submerge the crop is different than the case where crops are immersed and sitting in water for a longer period. Under extreme weather conditions such as severe rainfall or hurricanes which have led to prolonged standing water and/or actual flooding, a determination will need to be made regarding whether crops were inundated with floodwater. Any truly flooded crop is considered adulterated by the FDA, cannot be sold, and must be discarded as contaminated produce (Produce Safety Alliance 2018).

When signs of animals, weather events, or other potential contamination problems are suspected (e.g., overspray of liquid manure, manure run-off from adjacent fields, spills), you will need to determine what will and will not be harvested. It is important to document any corrective actions you decide to take in a pre-assessment log sheet, such as cordoning off the contaminated production area, discarding a portion of a given crop area, etc. The log should detail any observations about the affected production areas, dates of both occurrence and observation, what corrective actions were taken (if needed), and if any product was discarded (when warranted). Documenting with a log in this way will provide a descriptive record of your assessment and actions.

Reducing Risks During the Harvest Stage

Harvest Materials, Equipment, Machinery, and Vehicles

To prevent produce contamination from occurring during harvest, all harvesting tools (pruners, clippers, spade forks, etc.), utensils (knives), containers, equipment, and vehicles that come into direct contact with fresh produce should be kept clean, and in good repair. These items should be cleaned and/or sanitized on a scheduled basis (Figure 3). Once cleaned, smaller hand tools should be stored in sealable plastic bins or kept clean until they are ready for use. Picking containers, totes, bins, and bags should be designated for only harvesting produce and should not be used to carry or store any non-produce items. It is a good idea to store cleaned totes, bins, and containers stacked upside down (when possible), off the ground, and in a location that prevents them from becoming soiled or prone to animal intrusion and other sources of contamination. Any containers that are damaged should be assessed to see if they can be properly repaired; if they are irreparable they should be discarded. Any trailers or wagons used for moving harvest containers or bins through the field should also be cleaned and maintained to avoid cross-contamination.

Figure 3. Bulk containers, bins, tools, and utensils that come in contact with harvested produce must be cleaned and/or sanitized for the harvesting process. (Amber Vallotton, Virginia Cooperative Extension)

When mechanical harvest equipment and/or machinery is used, it should be assessed to make sure it does not pose any potential contamination hazards (Figure 4). Equipment and machinery should be inspected for overall cleanliness as much as possible, especially examining tires and machine parts that might have contacted any areas used for animal production, manure storage, and/or vehicular movement from these areas. Tractor light bulbs and glass should have protective covers to reduce the risk of breakage and introducing physical hazards in production fields. Likewise, corrective measures should be in place in case of glass or hard plastic breakage that would result in potential produce contamination. All hydraulic lines and mechanical parts should be monitored to ensure functionality and stability. If a malfunction occurs and product is contaminated by the leakage of hydraulic fluids, lubricants, petroleum, or other chemicals, then the situation must be assessed. For example, if a mechanical potato digger is used for harvesting, and the hydraulic line is accidentally cut and hydraulic fluid leaks onto the field, it would be important to assess the affected leakage site, how much of the potatoes may be contaminated, and what, if any, remediation to the soil needs to occur to safely harvest. A log should be used to document the incident and corrective action(s) taken.

Figure 4. Mechanical equipment like conveyor systems, harvesters, and diggers should be inspected for cleanliness, functionality, and other potential contamination hazards. (Amber Vallotton, Virginia Cooperative Extension, except second photo from left, Wythe Morris).

Water and Ice Used for Product Cooling

As discussed previously in the series (Bardsley et al. 2021a, b), water and ice can transfer biological hazards to fresh produce. USDA Harmonized GAP audit guidance states that any water or ice used for rapid pre-cooling of produce “must meet the microbial standards for drinking water…in order to be considered ‘safe and sanitary’” (USDA 2016, 80). Water or ice applied to produce for cooling should always be tested to make sure it is potable. Since surface water is considered unsafe without further testing, it should not be applied to finished product. If ice is made on the premises, ice machines should be cleaned on a regular basis. Plastic shovels, scoops, and receptacles used to transfer ice into containers used for field cooling should also be cleaned, sanitized, and not a source of contamination. During cooling or submersion processes, water or ice baths should be carefully monitored for visual signs of foreign matter. If mechanical systems such as hydro-coolers or spray systems are used, they should have a regular inspection, maintenance, and cleaning schedule.

Packing Produce in the Field

Field packing can mean harvesting the produce into its final packaging prior to being transported off the farm; it can also mean harvesting the produce into temporary containers or bins that are transported to on-farm packing areas or moved off-the-farm, where there may be further steps before re-packing. Some examples include directly harvesting sweet corn into mesh bags; harvesting broccoli into bulk bins; harvesting pumpkins into large cardboard boxes; and harvesting blackberries into clamshells (Figure 5). Having established field packing procedures are important to avoid potential issues in the field. Streamlining each step of the packing process will minimize lengthy exposure to temperatures that can reduce the quality of the harvested produce (see Vallotton et al. 2021c). All cardboard packaging materials and reusable bins should be properly stored to protect them from rodents, birds, dirt, dust, chemicals, and other hazards. It is best to physically separate any packaging materials and bins from other hazards (e.g., chemicals, fertilizers, tools, office supplies, etc.) to reduce chances of cross- contamination. Pre-assembling cardboard bins prior to going out to the field will reduce time in the field, but it is important to keep the bins in a protected place between assembly and use.

Figure 5. Examples of field-packed produce including sweet corn in mesh bags, broccoli in plastic bulk bins, pumpkins in pre-assembled cardboard bins, and blackberries in clamshells. (Amber Vallotton, Virginia Cooperative Extension, except second photo from left, Tanner Edwards)

Movement of Produce from the Field

Protocols should be established for transport vehicles used to move produce from the field. This includes protection of the harvested produce from contamination and the maintenance, cleaning, and overall condition of the transport trailers and vehicles. Address practices to minimize contamination from the field locations to the packing and/or storage areas (Figure 6). If you have a pre-set arrangement with a buyer to pick up the produce in the field, then you should have conveyance protocols that specify the way transactions will occur, and expectations for their vehicles/trucks in terms of cleanliness, temperature control, handling of the produce into the vehicle, and comingling issues. More details about post-harvest transport and conveyance can be found in Vallotton et al. 2021c.

Figure 6. Examples of preventative practices to reduce contamination of harvested produce. From left to right: bagged sweet corn covered with a clean sheet; a covered trailer placed in the shade in which harvested clamshells with berries are placed into secondary containers prior to movement back to a packing shed; and a canvas-covered trailer that is used to move melons to an on-farm storage area and is equipped with roll-down sides used during transport to a nearby produce auction. (Amber Vallotton, Virginia Cooperative Extension)

Traceability

All harvested produce should adhere to traceability protocols, whether field packed or moved to a packing area for re-packing (Bihn et al. 2014). Produce must be labeled to facilitate traceability back to the farm once the produce is sold. Numeric traceability codes are unique depending on what information is included for each lot harvested.

At a minimum, each lot should include a harvest date code, a crop code (type and variety), and a field (greenhouse, high tunnel) code where it was grown. Field codes should match assigned codes on your field farm maps. In some instances, farms also include harvest crew and packing date codes (e.g., orchards, large acreage arms). Use a traceability system that makes the most sense for your situation.

If produce is field packed, you will need a way to label the produce containers so that they coincide with your invoice system. This means making sure that the traceback code is not only put on the unit of product (e.g., bag, box, bin, pallet, etc.), but also matches the invoice paperwork with the same code. For produce that is harvested and repackaged in a separate packing area on your farm, there must be a way to trace the produce back to the production area from where it was harvested.

Some ways traceback can be done include creating a picking slip that is attached to larger bins, writing field codes on the side of large boxes, and creating laminated codes placed in harvested bins (Figure 7). The main objective is to be able to use the information to create traceback codes when re-packing into new containers, boxes, etc. While having a harvest log is helpful for knowing what, where, who, and when a crop was harvested, it can be challenging to connect the information to specific containers and bins, especially when the same type of produce is being harvested from multiple locations.

Figure 7. Different ways of tracking harvested produce from field to packing area. (Amber Vallotton, Virginia Cooperative Extension)

On-Farm Produce Safety Harvest Stage Checklist

Use the list of items below as a guide to tasks that should be completed as a part of your on-farm food safety program. Once each task is conducted, check off that item. For items that do not apply to your operation, write N/A next to the item.

For each crop, determine specific harvesting procedures you plan to use, such as how you will harvest (hand versus mechanical), tools and equipment needed, harvest containers/totes or bulk bins, and location of packing once produce is harvested.

Do you plan to directly field pack, will produce be taken to a packing area, or will product be packed in the field and moved directly to the marketplace or transported to another packing facility?

Develop a pre-harvest assessment checklist to keep you organized and provide a record for each harvest event:

Assess field or protected culture locations to verify there is no sign of contamination such as animal feces, animal tracks, feeding, or burrowing, and determine if extreme weather events have recently occurred that could indicate crops have been flooded.

Verify the cleaning and sanitizing of harvesting tools, utensils, harvest bins/ totes, and trailers.

Make sure harvest wagons and machinery are clean, in good repair, and lights are protected to prevent glass breakage.

Use food-grade lubricants for harvesting machinery.

For produce moved from fields to open packing sheds, pole barns, or similar structures, observe for signs of birds roosting or presence of other animals.

Put preventive measures in place such as adding bird screening or rodent traps.

For produce moved to an enclosed packing location, create protocols for preventing cross contamination by the movement of harvest containers/bins, tools, and tractors/trailers.

Create a traceability system and protocols that cover:

Invoicing field-packed products

Tracing harvested crops from field production locations to the packing area

Make sure harvest procedures include what workers will do regarding dropped and other visibly damaged or contaminated produce.

- Name

- Signature

- Date

References

Bardsley, C., A. Edwards, L.K. Strawn, and A. Vallotton. 2021a. Assessing On-Farm Food Safety Risks: Performing a Hazard Analysis. Virginia Cooperative Extension.

Bardsley, C., A. Edwards, L.K. Strawn, and A. Vallotton. 2021c. Assessing On-Farm Food Safety Risks: Pre- Plant Stage. Virginia Cooperative Extension.

Bihn, E.A., M.A. Schermann, A.L. Wszelaki, G.L. Wall, and S.K. Amundson. 2014. On-Farm Decision Tree Project: Traceability. Cornell University.

Callejón, R. M., M.I. Rodríguez-Naranjo, C. Ubeda, R. Hornedo-Ortega, M.C. Garcia-Parrilla, and A.M. Troncoso. 2015. Reported Foodborne Outbreaks due to Fresh Produce in the United States and European Union: Trends and Causes. Foodborne Pathog Dis. 12, 32–38. doi:10.1089/fpd.2014.1821.

Painter, J. A., R.M., Hoekstra, T. Ayers, R.V. Tauxe, C.R. Braden, F.J. Angulo, et al. 2013. Attribution of Foodborne Illnesses, Hospitalizations, and Deaths to Food Commodities by Using Outbreak Data, United States, 1998–2008. Emerg. Infect. Dis. 19, 407–415. doi:10.3201/eid1903.111866.

Produce Safety Alliance. 2018. Food Safety for Flooded Farms.

Produce Safety Alliance. 2019. Module 5, Part 2 – Postharvest Water, v.1.2. Cornell University.

USDA. 2016. Auditor Manual: Produce GAPs Harmonized Food Safety Audit Program, Policies and Procedures.

Vallotton, A., Bardsley, C., A. Edwards, and L.K. Strawn. 2021c. Assessing On-Farm Food Safety Risks: Post- Harvest Handling Stage. Virginia Cooperative Extension.

Resources

Boyette, M., L.G. William, and E. Estes. 1989. Proper Postharvest Cooling and Handling Methods.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

January 20, 2022