Food Safety Basics: Application to a Multistate Salmonellosis Outbreak Linked to Peanut Butter

ID

FST-508NP

Introduction

Contamination and persistence of pathogenic microorganisms on food can lead to outbreaks of foodborne illness. Investigating the food source that caused the illness, identifying how the pathogen entered the food production environment, and how the pathogen survived in the food product are important for preventing future outbreaks. Here we define foodborne illness outbreaks, traceback investigations, and apply basic microbial growth principles to a foodborne outbreak of salmonellosis linked to peanut butter.

Foodborne Illness Outbreaks

Controlling the growth of spoilage and pathogenic microorganisms is important to maintain food quality and safety. The growth of spoilage microorganisms leads to undesirable sensory changes in food, such as off-odors, textures, or taste. However, the growth of pathogens in food often goes undetected because these organisms do not always produce the same kinds of observable changes. Additionally, spoilage microorganisms cause noticeable sensory changes at much higher cell counts (millions) than the number that pathogens require (thousands) to cause foodborne illness. As a result, a pathogen can grow to an unsafe level and cause illness before the food shows signs of spoilage.

When two or more people become sick with similar symptoms from consuming the same food (such as a food contaminated with a pathogen that leads to a foodborne illness), this is considered a foodborne illness outbreak (CDC, 2024). When these outbreaks occur across state lines, they can be termed “multistate outbreaks”.

Traceback Investigations

The U.S. Centers for Disease Control and Prevention (CDC) is the agency responsible for surveillance of foodborne illness. Often, the CDC will work with state and local health departments to gather data on reportable foodborne illnesses. When a foodborne illness outbreak is suspected, the CDC, often in partnership with the U.S Food and Drug Administration (FDA) or the U.S. Department of Agriculture (USDA), initiates a process to identify the specific food that caused the illness, called “traceback” (FDA, 2023).

A traceback investigation works backward through the supply chain, starting at food retailers (e.g., grocery stores, restaurants, etc.), to distribution centers (e.g., warehouses), to food processing facilities, to farms (where the raw ingredients are sourced), to identify at what stage the contamination occurred. Traceback investigations ultimately allow public health alerts and product recalls to be issued and corrective actions to be implemented so future outbreaks can be prevented (FDA, 2023).

Introduction to the 2006-2007 Salmonellosis Outbreak Linked to Peanut Butter

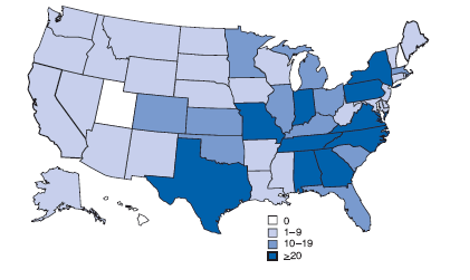

An example of a multistate foodborne illness outbreak is the 2006-2007 incident of salmonellosis in peanut butter. This multistate outbreak occurred from August 2006 through May 2007. A reported total of 628 people across 47 states became sick with salmonellosis (Figure 1); however, the true number of infections is likely higher because not everyone visits the doctor when they become sick, resulting in the illness going unreported. A traceback investigation found the source of contamination to be from a single plant manufacturing the peanut butter product (CDC, 2007).

Salmonella enterica subsp. enterica, often referred to simply as “Salmonella,” is a bacterial pathogen that causes a foodborne illness called “salmonellosis.” Salmonella enterica subsp. enterica is further grouped into serotypes (or serovars), which is how the pathogen may be identified when outbreaks occur (FDA, 2023). Salmonella serotype Tennessee was the cause of this outbreak linked to peanut butter.

The type of foodborne illness that Salmonella causes is called an “infection”, which means that consuming the microorganism in sufficient numbers can make someone sick. Even if that microorganism is not growing in the food (increasing its numbers), the microorganism can still cause illness because of the number of microorganisms already in the food product when it is consumed.

Steps to Prevent Pathogen Contamination of Food

Preventing the entry of Salmonella into the food processing environment or the food product is an important first line of defense in preventing food contamination and outbreaks. Salmonella can make its way into the processing environment, and ultimately the food product, through raw ingredients (e.g., peanuts, sugar), air, water, equipment, employees, and pests (Beuchat et al. 2011, CDC, 2007), as shown in Figure 2.

Prevention of entry alone may not always be possible to control pathogens in a food, especially in cases where pathogen presence on raw ingredients is likely (i.e., you cannot always prevent entry of ingredients into your operation). The use of a validated kill step and controlling microbial growth factors to reduce growth are important additional strategies for reducing food safety risks. Controlling the growth of microorganisms in food is accomplished by the manipulation of one or more of six primary factors required for microbial growth. These factors are often abbreviated as “FATTOM”: food (nutrients), acidity (pH), time, temperature, oxygen (atmosphere), and moisture (water activity).

How Microbial Growth Factors Impacted the Outbreak

The 2006-2007 salmonellosis outbreak linked to peanut butter was likely caused by the combination of Salmonella’s (1) entrance into the processing facility through a storm-damaged sugar silo and leaky roof which led to the contamination of raw ingredients, (2) failure to carry out an effective kill step due to damaged equipment, and (3) persistence of the pathogen in the food (FDA, 2016). While Salmonella did not grow in the peanut butter, it was able to survive for months and retain the ability to cause illness due to support from microbial growth factors inherent to the food product and the environment in which it was produced.

Food (Nutrients)

Peanut butter is typically produced by first roasting raw peanuts, then blanching, grinding, and mixing in additional ingredients such as sugar and salt (Ma et al. 2009). The free carbohydrates, proteins, and high-fat content of peanut butter help Salmonella survive; in fact, some researchers suggest the high-fat content can protect Salmonella from heat treatments (Shachar and Yaron, 2006).

Acid (pH)

High acid foods (pH <4.6) can prevent or significantly reduce the growth of pathogenic bacteria; however, low acid foods (pH >4.6) cannot do this as effectively. Peanut butter has a final pH of approximately 6.1-6.4 (Sithole et al. 2022), which can vary based on the recipe used. Since Salmonella can grow in pH ranges from 4.2-9.0, the pH of the peanut butter on its own is not sufficient to kill the pathogen.

Time

Commercially produced peanut butter products typically have a shelf-life of 6 to 9 months at ambient temperature (Kataoka et al. 2014). The duration of this outbreak was approximately 9 months, indicating in this case that Salmonella was able to persist in the peanut butter and cause illness upon consumption, possibly throughout the product’s shelf-life.

Temperature

Thermal inactivation (heating) is a pathogen control strategy that can effectively eliminate pathogen presence in a food product, as long as the heat treatment is properly applied (cooked to the right temperature for the right amount of time) and protected from re-contamination after heating. Additionally, storage temperatures of finished food products should also be considered when preventing the growth of microorganisms (spoilage or pathogenic) during a product’s shelf-life.

For peanut butter, the initial roasting process heats raw peanuts to approximately >150°C (302°F), which is able to kill Salmonella (Sheth et al. 2014, Sithole et al. 2022). However, the traceback investigation showed that improper roasting of contaminated raw peanuts due to damaged equipment may not have sufficiently killed Salmonella, which means it survived the roasting process on the peanuts.

Further, because Salmonella can survive in peanut butter stored at room temperature (23°C/73.4°F), as peanut butter products are typically shipped and sold, storage temperature alone is not sufficient to kill or inhibit the growth of this pathogen (Burnett et al. 2001).

Oxygen (Atmosphere)

Salmonella is a facultative anaerobe, meaning it can grow and survive in environments with or without oxygen present. Peanut butter is sealed in a hard plastic or glass jar with some headspace remaining between the product and the seal. Since Salmonella was likely mixed throughout the product in the grinding and mixing steps, the pathogen could have been present at any point in the container, from the anaerobic (oxygen-free) interior to the aerobic (oxygen-containing) headspace. Regardless, the packaging of the product (or the atmosphere in which it is packaged) would not kill or prevent the growth of Salmonella on its own.

Moisture (Water Activity)

Moisture content refers to the total water within a food and is expressed as a percentage of the total product weight; whereas water activity (aw) is the measure of free water available for microbial growth and is measured on a scale from 0.0-1.0. The lower the aw value (closer to 0.0), the less free water is available for microorganisms to grow; conversely, the higher the aw value (closer to 1.0), the more free water is available for microorganisms to grow. If there is not enough free water available for microorganisms to use, they cannot grow.

The FDA considers a food product to be “water activity-controlled”, meaning the growth of pathogenic bacteria is prevented, if the final aw is less than or equal to 0.85 (FDA, 2014). Peanut butter is considered a “low-moisture”, “low water activity”, or “water activity-controlled” product, relying on its low water activity (aw = 0.20-0.45) as the primary control to prevent microbial growth (Finn et al. 2013, Kataoka et al. 2014).

Salmonella requires a aw > 0.85 for growth, so while it does not grow in low water activity foods such as peanut butter, it can persist for extended periods of time (Kataoka et al. 2014). Because Salmonella can cause foodborne illnesses without growing if enough cells are present, water activity control alone is not always sufficient to prevent illness.

Key Learnings

The 2006-2007 salmonellosis outbreak in peanut butter was caused by the entry of Salmonella into the processing facility, the subsequent contamination of raw ingredients, failure to effectively implement a kill step (i.e., roasting), and the persistence of the pathogen in the peanut butter through the duration of the product’s shelf-life, according to a press release on the outbreak by the FDA Office of Criminal Investigations (FDA, 2016). The six primary microbial growth factors influenced the survival of Salmonella in the peanut butter product throughout processing and the shelf-life.

Key strategies to ensure product safety by reducing food safety risks include (1) preventing pathogen entry into the food processing environment or the food product, (2) use of a validated kill step during food processing (e.g., heating), and (3) controlling the growth of microorganisms in the food product through the manipulation of one or more of six primary microbial growth factors.

Additional Resources

U.S. Food and Drug Administration – Get the Facts About Salmonella: https://www.fda.gov/animal-veterinary/animal-health-literacy/get-facts-about-salmonella#resources.

U.S. Food and Drug Administration – How the FDA Uses Traceback to Respond to Foodborne Illness Outbreaks: https://www.fda.gov/food/outbreaks-foodborne-illness/how-fda-uses-traceback-respond-foodborne-illness-outbreaks.

U.S. Food and Drug Administration - Safety Tips for Consumers & Retailers During an Outbreak of Foodborne Illness: https://www.fda.gov/food/outbreaks-foodborne-illness/food-safety-tips-consumers-retailers-during-outbreak-foodborne-illness.

U.S. Centers for Disease Control and Prevention – Multistate Food Outbreak Notices: https://www.cdc.gov/foodborne-outbreaks/active-investigations/all-foodborne-outbreak-notices.html.

References

Beuchat, L., Komitopoulou, E., Betts, R., Beckers, H., Bourdichon, F., Joosten, H., Fanning, S., & ter Kuile, B. (2011). Persistence and survival of pathogens in dry foods and dry food processing environments. (ILSI Europe report series). ILSI Europe. http://www.ilsi.org/Europe/Documents/Persistence%20and%20survival%20report.pdf" target="_blank">http://www.ilsi.org/Europe/Documents/Persistence%20and%20survival%20report.pdf.

Burnett, S. L., Gehm, E. R., Weissinger, W. R., & Beuchat, L. R. (2000). Survival of Salmonella in peanut butter and peanut butter spread. Journal of applied microbiology, 89(3), 472-477. https://doi.org/10.1046/j.1365-2672.2000.01138.x.

U.S. Centers for Disease Control and Prevention (CDC). 2007. Multistate Outbreak of Salmonella Serotype Tennessee Infections Associated with Peanut Butter --- United States, 2006—2007. https://www.cdc.gov/mmwr/preview/mmwrhtml/mm5621a1.htm#fig2.

U.S. Centers for Disease Control and Prevention (CDC). 2024. Confirming an Etiology in Foodborne Outbreaks. https://www.cdc.gov/foodborne-outbreaks/php/investigating-outbreaks/confirming_diagnosis/index.html#:~:text=A%20foodborne%20disease%20outbreak%20is,Reporting%20System%20(NORS).**

U.S. Food and Drug Administration (FDA). 2014. Water Activity (aw) in Foods. https://www.fda.gov/inspections-compliance-enforcement-and-criminal-investigations/inspection-technical-guides/water-activity-aw-foods.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

July 24, 2025