ENERGY SERIES: What about Windows?

ID

2901-9010 (BSE-297NP)

How Can I Determine the Energy Performance of a Window?

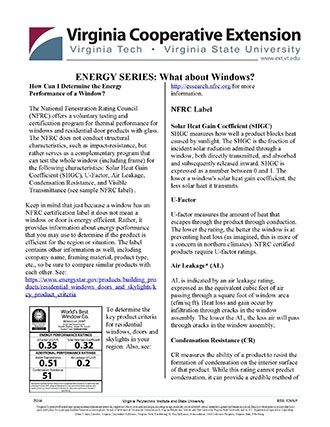

The National Fenestration Rating Council (NFRC) offers a voluntary testing and certification program for thermal performance for windows and residential door products with glass. The NFRC does not conduct structural characteristics, such as impact-resistance, but rather serves as a complementary program that can test the whole window (including frame) for the following characteristics: Solar Heat Gain Coefficient (SHGC), U-Factor, Air Leakage, Condensation Resistance, and Visible Transmittance (see sample NFRC label) .

Keep in mind that just because a window has an NFRC certification label it does not mean a window or door is energy efficient. Rather, it provides information about energy performance that you may use to determine if the product is efficient for the region or situation. The label contains other information as well, including company name, framing material, product type, etc., so be sure to compare similar products with each other. See: https://www.energystar.gov/products/building_products/residential_windows_doors_

and_skylights/key_product_criteria

To determine the key product criteria for residential windows, doors and skylights in your region. Also, see:

http://essearch.nfrc.org/ for more information.

NFRC Label

Solar Heat Gain Coefficient (SHGC)

SHGC measures how well a product blocks heat caused by sunlight. The SHGC is the fraction of incident solar radiation admitted through a window, both directly transmitted, and absorbed and subsequently released inward. SHGC is expressed as a number between 0 and 1. The lower a window's solar heat gain coefficient, the less solar heat it transmits.

U-Factor

U-factor measures the amount of heat that escapes through the product through conduction. The lower the rating, the better the window is at preventing heat loss (as imagined, this is more of a concern in northern climates). NFRC certified products require U-factor ratings.

Air Leakage* (AL)

AL is indicated by an air leakage rating, expressed as the equivalent cubic feet of air passing through a square foot of window area (cfm/sq ft). Heat loss and gain occur by infiltration through cracks in the window assembly. The lower the AL, the less air will pass through cracks in the window assembly.

Condensation Resistance (CR)

CR measures the ability of a product to resist the formation of condensation on the interior surface of that product. While this rating cannot predict condensation, it can provide a credible method of comparing the potential of various products for condensation formation. CR is expressed as a number between 0 and 100. The higher the CR rating, the better that product is at resisting condensation formation. This rating is optional and manufacturers can choose not to include it.

Visible Transmittance (VT)

VT measures how much light comes through a product. The visible transmittance is an optical property that indicates the amount of visible light transmitted. VT is expressed as a number between 0 and 1. The higher the VT, the more light is transmitted.

Are Energy Star Windows Available?

Yes! Look for Energy Star windows for your particular climate. Remember to comparison shop using the NFRC label.

What Types of Window Design Should I Consider When Building a New Home? Good window designs start at a minimum of three feet off the floor and end at a maximum of six to seven feet from the floor. This design allows people to see out of the window while sitting or standing, without excess glass area. Avoid designs that call for sheets of glass installed directly into the walls, as plain glass is a poor energy performer.

How Can I Make Current Windows Perform Better in an Existing Home?

Windows should shut tightly when closed. To provide a better seal, rubber gaskets are available for certain types of windows. Add shutters, awning, and/or solar screens where excessive solar gain is a problem. Check caulking and weather-stripping on windows annually. Damaged weather-stripping and caulking should be removed and replaced.

How Should a Window be Installed?

The proper attachment of the window to the structure is critical to the performance of the window. Each manufacturer specifies how its windows must be installed.

Detailed information about window and door installation is provided by the American Society for Testing and Materials (ASTM) in ASTM E2112 - 19c: Standard Practice for Installation of Exterior Windows, Doors and Skylights. Look for an installer who has extensive experience, and is familiar, with this document or other installation specifications as available through the American Architectural Manufacturers Association (AAMA) and who follows the manufacturer’s installation guidelines.

What is Tempered Glass?

Note that tempered glass windows and impact- resistant windows are not the same. Tempered glass is one type of heat-treated glass in which the glass is first heated, and then the surface is rapidly cooled. This treatment results in the center of the glass remaining relatively hot compared to the surface. As the center thickness cools, it compresses the surfaces and edges.

When tempered glass does break, it fractures into small, relatively harmless fragments. This phenomenon, often referred to as “dicing,” greatly reduces the likelihood of injury to people.

Many building codes require safety glazing material, such as tempered glass, where there is a reasonable likelihood of exposure to human impact, as in door assemblies, bathtub or hot tub enclosures, railings or glass adjacent to stairways, etc. Safety glazing materials are designed to reduce the likelihood of cutting and piercing injuries when broken by human contact.

What is Impact-Resistant Glazing?

Impact-resistant glazing is available as laminated glass and is also considered a type of safety glazing. Laminated glass consists of two or more panes of clear glass bonded together with clear plastic-like film (usually polyvinyl butyral) sandwiched between the two. This inner “filling,” ranging in thickness from .015 to .090 inches and available in various colored tints to help reduce ultraviolet damage in the home, tends to hold the glass together upon impact. If cracked or broken, the glass fragments tend to adhere to the plastic interlayer thus preventing water, wind, or wind- borne debris from entering the structure.

Although the glass may not break, a strong force could hit the window hard enough to cause the entire frame to give way. Therefore, the frames for laminated glass are generally heavier than for regular residential windows. When undergoing testing, the window is tested as a unit that includes the glass, frame, attachment hardware, and the installation method. Products designed to protect your home's openings must be tested and approved for both wind load and wind-borne debris. There are testing standards set forth by the American Society for Testing & Materials (ASTM) and/or other organizations that must be met before a window is certified as being impact- resistant.

Keep in mind that all glass, other than impact- resistant window glass, even if tempered, reinforced, or insulated needs to be protected during severe wind events.

Developed as part of the NASULGC/DOE Building Science Community of Practice. The factsheet editors are: Robert "Bobby" Grisso, Ph. D., Extension Engineer, Biological Systems Engineering; Martha A. Walker, Ph.D, Community Viability Specialist, Central District; Philip Agee, Ph. D., Assistant Professor, Department of Building Construction, and John Ignosh, Extension Specialist, Biological Systems Engineering, Virginia Tech.

DISCLAIMER – This piece is intended to give the reader only general factual information current at the time of publication. This piece is not a substitute for professional advice and should not be used for guidance or decisions related to a specific design or construction project. This piece is not intended to reflect the opinion of any of the entities, agencies or organizations identified in the materials and, if any opinions appear, are those of the individual author and should not be relied upon in any event.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

March 20, 2020