Powell River Project - Reclamation of Coal Refuse Disposal Areas

ID

460-131 (CSES-215P)

EXPERT REVIEWED

Introduction

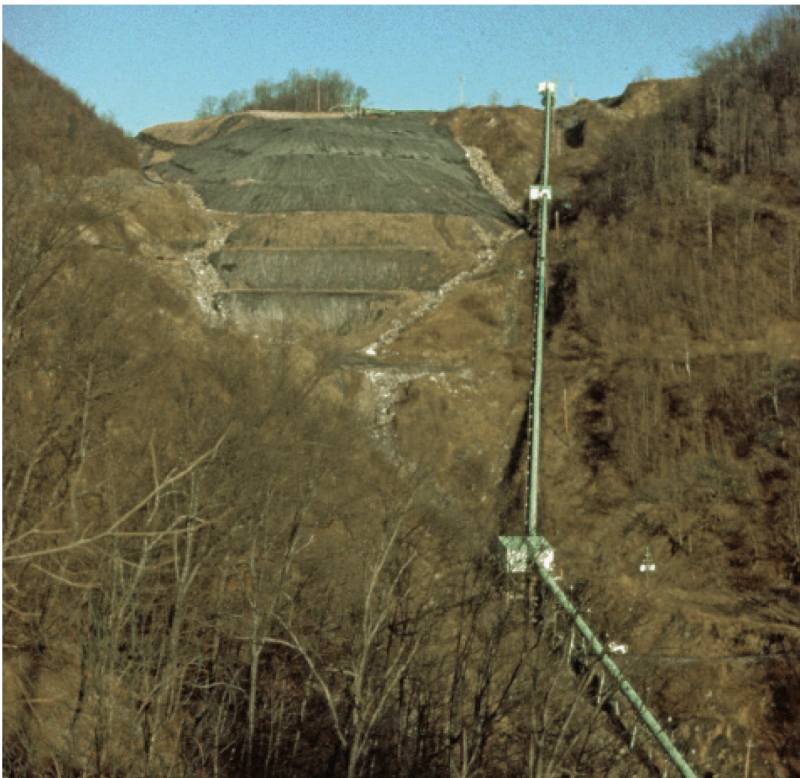

Stabilization and reclamation of coal refuse disposal piles and fills are costly and challenging problems facing the Appalachian coal industry today. Coal refuse disposal areas are also known as “gob piles,” “slate dumps,” “waste piles,” and “refuge.” The exact acre-age of coal refuse in the Appalachian coal fields is difficult to estimate, but active disposal facilities (figure 1) cover thousands of acres, and abandoned refuse piles dot the landscape in almost every major watershed. We estimate that annual production of coal refuse exceeds 10 million tons in Virginia alone.

This publication reviews problems associated with stabilization and revegetation of coal refuse disposal areas and suggests strategies for their successful long-term reclamation and closure. The primary focus is establishment of vegetation, but other refuse stabilization issues are discussed. The reader is encouraged to consult the papers and reports cited in the references section for specific details and technical data. The regulatory framework discussed in this paper is specific to Virginia, but it is similar to that of other coal-mining states in the Appalachian coal region.

Modern coal-cleaning technologies have allowed coal preparation facilities to become quite efficient at removing sulfur compounds, waste rock, and low-grade coals from run-of-mine coal. Up to 50 percent of the raw, mined product may end up as refuse, particularly when the coal originates from longwall mining operations — thin, underground seams where some roof must be removed with the coal in order to assure adequate space for miners and equipment — or from seams that are high in partings, rock, and impurities. The refuse mate rials vary from coarse fragments removed by physical screening to very fine materials removed by flotation and density separation processes.

The potential hazards of improperly reclaimed refuse include contamination of surface and groundwater by acidic leachates and runoff, erosion and sedimentation into nearby water bodies, spontaneous combustion, and damage from landslides. While these problems were common on refuse piles constructed prior to the 1970s, modern regulations attempt to minimize the environmental impact of coal refuse disposal.

Several, if not all, of the problems associated with coal refuse piles can be reduced significantly with the maintenance of a viable plant cover. A vigorous plant community can reduce water and oxygen movement down into the fill, thereby limiting the production of acidic leachates while reducing sediment losses and stabilizing the fill surface. Establishment and maintenance of permanent vegetation on refuse, however, is complicated by physical, mineralogical, and chemical factors.

Regulatory Framework and Reclamation Strategies

Reclamation standards for refuse disposal in Virginia are set forth in the Permanent Regulatory Program of the Virginia Division of Mined Land Reclamation (VDMLR; see Virginia Department of Mines, Minerals and Energy, Virginia Administrative Code). The state regulations and performance standards are subject to oversight and review by the U.S. Office of Surface Mining Reclamation and Enforcement and must meet the minimum standards set forth in the federal Surface Mining Control and Reclamation Act (SMCRA) of 1977.

An important aspect of these regulations is the five-year bond liability period. Before reclamation bond monies are completely released, refuse disposal areas must support self-sustaining vegetation for a minimum period of five years after closure. Leachate and runoff must meet water quality standards for this same period, and there must be evidence that water quality will not degrade over the long term.

Refuse disposal areas are generally constructed as large valley fills, with surface water diverted around or through drains under the completed fill. These fills are commonly hundreds of acres in size and are perched in the headwaters of many watersheds. The refuse is compacted into place, and the entire fill must meet rigorous geotechnical stability standards. Many refuse disposal areas are constructed using a “zoned disposal” concept, where refuse slurry generated in the fine-coal-cleaning circuit is impounded behind a compacted dam of coarse refuse. The face and sideslopes of the fills are generally constructed to a steep gradient to minimize the total disturbed area, and these steep slopes greatly com-plicate reclamation. Most fills are designed for a life-time of tens of years. Therefore, many active fills were designed before current regulations were in force.

Once the fill is completed, regulations require that “the site shall be covered with a minimum of 4 feet of the best available nontoxic and noncombustible materials” unless a suitable alternative reclamation strategy is employed. Less than 4 feet of cover materials may be used if chemical and physical analyses indicate its properties are conducive to establishing a permanent vegetative cover and the applicant can prove that the standards for revegetation success can be met. Thick topsoiling is quite costly and may be impractical in areas where native soils are shallow. Extensive topsoiling also creates the problem of reclaiming the borrow areas.

Coal refuse disposal areas are required to meet the same standards for revegetation success following the five-year bond liability period as surface-mined sites. Top-soiling or covering with surface mine spoils (topsoil substitutes) may be the only option available on some sites due to toxic properties of the materials, but direct-seeding appears to be a viable alternative for some refuse materials. Documented field trials have generally been required to evaluate the suitability of refuse materials as a plant-growth medium via direct-seeding because reliable laboratory testing methods that correlate with plant-growth response have not been available. It is our belief, however, that many coal refuse piles can be successfully direct-seeded by following the procedures outlined in this paper without long-term, dedicated on-site experimental trials.

Coal Refuse Properties and Reclamation Success

The long-term stability of any reclaimed coal waste pile is largely dependent upon the ability of surface treatments (including soil cover) to establish a favorable plant-rooting environment. Failure to maintain long-term vegetation results in excessive erosion and gullying. Lack of a plant cover will also cause subsurface water contents and leachate production to increase due to lack of rain interception by the plant canopy and decreased plant transpiration. The key to developing successful long-term reclamation strategies is an understanding of the nature and variability of the coal refuse materials and how they will respond to various treatments over time. Long-term closure planning must also consider the potential of the pile to generate acid mine drainage (AMD).

Many factors influence the reclamation potential of a given coal waste pile, including the geologic source of the refuse, the prep-plant processes, and local site conditions. The following sections summarize properties and conditions known to influence refuse pile reclamation and surrounding environmental quality and relate them to reclamation planning.

Geologic Considerations and Prep-Plant Influences

The depositional environment of coal and its associated strata has a direct relationship to the properties of the coal seams, including coal bed thicknesses, sulfur and trace element content, and coal quality. Like natural soils, the primary components of coal refuse are minerals that contain silicon and aluminum. However, coal refuse differs from most natural soils in other ways. Depending on its pyrite content, the heavy metal content of coal refuse may be greater than is commonly encountered in natural soils. The total elemental content of 27 refuse materials sampled in southwestern Virginia in the late 1980s is similar to values for Appalachian coal refuse reported by other researchers (Rose, Robi, and Bland 1976; National Research Council 1979).

The correlation of paleoenvironment and coal properties has many important applications to both the mining and use of coal and to investigations into the nature of the wastes produced by mining. Although coal refuse shares many characteristics with the associated coal seams, coal refuse properties are also influenced by mining, coal cleaning, and geochemical weathering processes.

Coal refuse is usually composed of rock fragments derived from interseam shale or siltstone partings and waste rock materials from above or below the seam. The refuse shares many properties with the associated coal seam. For example, some coal seams are inherently high in sulfur (e.g., the Pittsburgh seam of northern Appalachia), some are low in sulfur (the Pocahontas seam of the south-central Appalachian Basin), and some are variable. Southwest Virginia coal seams and associated strata are generally low in sulfur compared to other Appalachian states. As a result, Virginia coal refuse tends to be comparatively low in sulfur and associated potential acidity (table 2).

The processes utilized in the prep plant also influence the physical and chemical properties of the refuse stream. Some prep plants recombine coarse-and fine-refuse fractions before disposal, while others dispose of these fractions separately or in zoned fills. Our work has focused on the reclamation of coarse refuse and recombined refuse materials and not on slurry impoundments. The approach to direct reclamation of slurry materials would be similar to that described here, once the surface has stabilized (Nawrot and Gray 2000). However, the most common practice is for slurry impoundments to be capped with coarse refuse and then reclaimed in similar fashion to the rest of the facility.

| Element | Mean | Median | Range |

|---|---|---|---|

| SiO2 | 391 | 408 | 202-552 |

| AlO2 | 128 | 133 | 62-196 |

| FeO2 | 41 | 42 | 22-77 |

| K2O | 28.9 | 30 | 9.9-48.8 |

| NaO | 3.1 | 3 | 0.5-5.9 |

| MgO | 5.6 | 4.8 | 1.5-17.8 |

| CaO | 2.1 | 0.5 | 0.1-19.2 |

| Element | Mean | Median | Range |

|---|---|---|---|

| Cu | 55 | 51.3 | 36.9-90.4 |

| Zn | 70.3 | 65.1 | 21.6-125.6 |

| Ni | 39.2 | 38.8 | 17.6-55.9 |

a Data from Stewart and Daniels (1992), Daniels and Stewart (2000).

| Element | Median | Range |

|---|---|---|

| SiO2 | 714 | 536-750 |

| AlO2 | 155 | 22-656 |

| FeO2 | 60 | 11-864 |

| K2O | 34 | 1-27 |

| NaO | 11 | 1-13 |

| MgO | 8 | 1-10 |

| CaO | 19 | 10-700 |

| Element | Median | Range |

|---|---|---|

| Cu | 20 | 2-100 |

| Zn | 50 | 10-300 |

| Ni | 40 | 10-1,000 |

b World soils’ estimates from Helmke (1999), converted to an oxide basis.

| Parameter | Median Value |

|---|---|

| % material > 2mm diameter | 60% |

| Fine-earth fraction: % material < 2mm diameter | 40% |

| Parameter | Median Value |

|---|---|

| % sand-sized (2.000-0.050 mm) | 60% |

| % silt-sized (0.050-0.002 mm) | 22% |

| % clay-sized (< 0.002 mm) | 15% |

| Soil textural class | sandy loam |

| Parameter | Median Value |

|---|---|

| Plant-available water | 0.8% |

| pH | 4.16 |

| EC | 0.04 S m-1 |

| Cation exchange capacity | 3.65 cmolc kg-1 |

| Available phosphorus (P) | 7.6 ppm |

| Potential acidity (acid-base accounting) |

10.2 tons CaCO3 / 1,000 tons refuse |

| Potential acidity (H2O2) | 27.8 tons CaCO3 /1,000 tons refues |

The content and reactivity of pyritic sulfur exert a dominant influence on refuse chemical properties over time. The efficiency of a preparation plant at removing sulfur from the marketed coal and the degree to which the sulfide fragments are fractured and reduced in size influence the reactivity and potential acidity of the final refuse product. Numerous reagents and additives such as anionic and cationic polymers, surfactants, oils, and strong bases are used in various separation and water treatment processes and also end up in the refuse stream to some extent. The influence of these additives on the revegetation potential of fresh refuse has not been studied.

Variable Properties

A high degree of variability often exists in refuse materials within the same disposal area, because individual prep plants often process several coal seams. Each seam may exhibit different mineralogical, chemical, and physical properties. This variability makes the development of uniform reclamation strategies difficult. Additional variability is introduced through weathering. Because coal refuse materials are primarily fresh, unweathered geologic materials that have been subjected to severe treatment during processing, sharp changes in physical and chemical properties are common over short periods of time. The pH of fresh refuse can change dramatically in a short period. We have observed the pH of a fresh, high-sulfur refuse change from 8.0 to 3.0 within a single month.

Slope and Aspect Effects

Modern refuse piles are engineered to maximize vol-ume capacity while minimizing their “footprint,” or the land area they occupy. Minimizing acreage necessitates the construction of steeply sloping embankments; these tend to be heavily compacted so as to maintain surface stability. Steep slopes complicate revegetation efforts in several ways. First, it can be very difficult to apply and incorporate soil amendments such as agricultural lime on steep slopes. Secondly, the steep slopes enhance rainfall runoff, which leads to droughty soil conditions. This soil water supply problem is further compounded by the compaction mandated to achieve slope stability. Finally, the microclimate of steeply sloping areas will be strongly influenced by aspect. South-facing fill slopes will be extremely hot in the summer while north-facing slopes are cooler and moister. Thus, regulatory and economic design pressures to limit the footprint of disturbance greatly complicate long-term stabilization and revegetation of refuse fills.

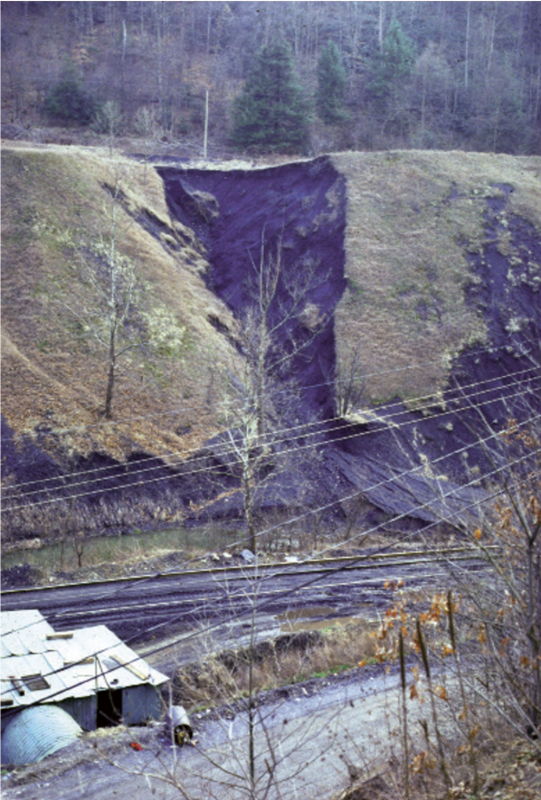

Older piles, which predate the enactment of SMCRA and VDMLR regulations, often have steeply sloping sides that remain uncompacted. Hard rain tends to cause the surfaces of these abandoned piles to slide downward, exposing fresh refuse. For successful revegetation, these slopes must be reconfigured to stable angles through regrading, and in some cases, with removal to an alternate location. No amount of vegetative cover will stabilize materials with fundamental slope instability problems. Fine-refuse particles washed from recently exposed surfaces present problems of acidification and sedimentation in nearby streams. This is predominantly a problem with abandoned piles, constructed prior to enactment of modern reclamation law, that are not under permit (figure 2).

Pyrite Oxidation and Potential Acidity

Many of the environmental problems associated with coal refuse occur as a result of pyrite oxidation and the production of acidity. Much of the total sulfur in refuse is present as pyrite (FeS2) and other sulfides that oxidize to sulfuric acid in the presence of water and oxygen. This highly acidified water is frequently less than pH 3.0 and dissolves the mineral matrix around it as it leaches downward, becoming charged with aluminum, manganese, and other metals, cations, and salts.

The pyrite reaction rate is dependent not only on the oxygen supply and microbial catalysis, but also on the size and morphology of pyrite particles. Two types of pyrite are commonly found in coal: Framboidal (fine) pyrite forms concurrently with the coal, while coarse-grained pyrite is a secondary product of coal formation and is usually found in former plant structures and joints in the coal. Framboidal pyrite particles (2-15 μ) have a high surface area and will oxidize rapidly. Coarse-grained pyrite is much less reactive. In some refuse materials, a large amount of the total sulfur is contained in relatively unreactive organic forms or as sulfate, one of the reaction products of the oxidation processes discussed above. Organic and sulfate forms of sulfur are not generally considered to be acid-producing. Thus, the total sulfur content of refuse is not as reliable a predictor of acid-producing potential as pyritic sulfur content is.

Freshly exposed pyritic refuse often has a near-neutral pH. After oxidation, pH values can drop dramatically, and many pyritic coal refuse materials have a very low (2.0 to 3.5) pH once they weather. After complete oxidation of sulfides and subsequent leaching of acid salts, the pH often rises into the low “4s” but is strongly buffered in that range by aluminum and other metals. The pH of a particular refuse material will depend not only on its pyrite content, but also on the length of exposure time and its acid-neutralizing capacity. Most coal refuse materials in the Appalachians contain an excess of oxidizable sulfur compared to neutralizing carbonates and are, therefore, net-acid-producing over time. The average fresh refuse material in Virginia requires 10 tons of calcium carbonate (CaCO3) per 1,000 tons of raw refuse to neutralize the acidity present, assuming complete reaction of pyrite and carbonates via the regular acid-base accounting technique (table 2). The potential acidity of refuse materials in West Virginia and Kentucky is often much higher, sometimes exceeding 50 tons of lime requirement per 1,000 tons.

The rate of pyrite oxidation and acid production is generally highest in the oxygenated surface layer, which is also the zone utilized by plant roots. A rapid drop in pH releases plant-toxic concentrations of acid-soluble metal ions into soil solution and reduces the availability of many plant nutrients. When the pH falls below 4.5, root growth of many plant species ceases. Another problem caused by pyrite oxidation is the production of sulfate salts, which may accumulate to toxic levels in the root zone. These salts are generally water-soluble and accumulate on coal wastes during dry periods as water is lost by surface evaporation. The whitish surface coating seen on refuse and coal piles during dry weather is evidence of this process (figure 3).

Acid Seepage and Leachate Production

While acid sulfate weathering processes drastically inhibit vegetation establishment, perhaps their greatest environmental impact is through acid leachate production. As drainage waters percolate through a refuse pile, leachates often become quite acidic and high in heavy metals. These leachates, collectively referred to as “acid mine drainage,” leave the pile as deep drain-age waters, sideslope springs, or in surface runoff. If not properly curtailed or treated, AMD poses a serious, long-term water quality threat. Seeps of AMD on steep fill sideslopes also pose a major revegetation problem.

Pyrite oxidation is catalyzed by acidophilic bacteria like Thiobacillus ferooxidans, which are ubiquitous in coal strata and are capable of functioning in very low oxygen (less than 1.0 percent partial pressure) environments. Therefore, as long as acid water is allowed to percolate through a refuse fill, pyrite oxidation will occur deep within the pile, regardless of surface revegetation and stabilization efforts. The net-leaching environment of the Appalachians assures that acid mine drainage is inevitable for any coal refuse pile that contains net-acid-forming materials. Due to the total mass of the pyrite in many refuse piles and the relatively slow rate of water movement through them, it is reasonable to expect that acid mine drainage will be emitted for decades, if not longer.

Spontaneous Combustion

Many older refuse piles are high in coal fragments; often, such piles were constructed in loose, unconsolidated configurations that allow oxygen to interact easily with the refuse. Because pyrite oxidation is an exothermic (heat-producing) reaction, spontaneous combustion of older refuse piles was a common occurrence. Combustion of older piles has also occurred due to burning trash, arson, forest fires, and other factors. Burning refuse piles pose local air quality problems and are virtually impossible to revegetate unless the burning is stopped.

Modern refuse piles are generally lower in coal than older piles due to improved coal-separation technologies and are compacted in place to limit air and water penetration. The thick topsoil requirement for refuse pile reclamation is also intended to further limit oxy-gen movement into the fill, although our results indicate that significant sulfur oxidation occurs in refuse, even under 4 feet of topsoil cover. Reports of combination of modern refuse fills are very rare. When they do occur, they are generally the result of arson or accidental ignition.

Low Fertility

Because coal refuse is composed mainly of weathered rock and coal fragments, plant-available nitrogen (N) and phosphorous (P) are generally low. Due to their weatherable mineral content, however, refuse materials can be expected to supply adequate levels of calcium (Ca), magnesium (Mg), and potassium (K) to plants. In general, reclamation of coal refuse materials requires substantial fertilization, particularly with nitrogen and phosphorus. However, even large applications of nitrogen can easily leach out of the rooting zone within one year if not assimilated into plant tissue. The majority of plant-available nitrogen after the first year must be supplied by legumes and is held primarily in organic matter forms over time. Therefore, the establishment and maintenance of legumes over the first season after seeding is critical to long-term revegetation success.

Soil phosphorus does not leach from the rooting zone in the same fashion as nitrogen; however, phosphorus is readily converted into soil mineral forms that are not available to plants. Soil phosphorus held in organic forms is protected against these losses, so the establishment and turnover of an organic matter pool in the reclaimed “refuse soil” is also critical for long-term phosphorus fertility. Organic amendments such as biosolids (sewage sludge) or composts supply large amounts of nitrogen and phosphorus in addition to their beneficial effects on the soil physical environment and should be considered for use on refuse piles when available (figure 4). For additional discussion of nitrogen and phosphorus behavior in mine soils, see Virginia Cooperative Extension (VCE) publication 460-121.

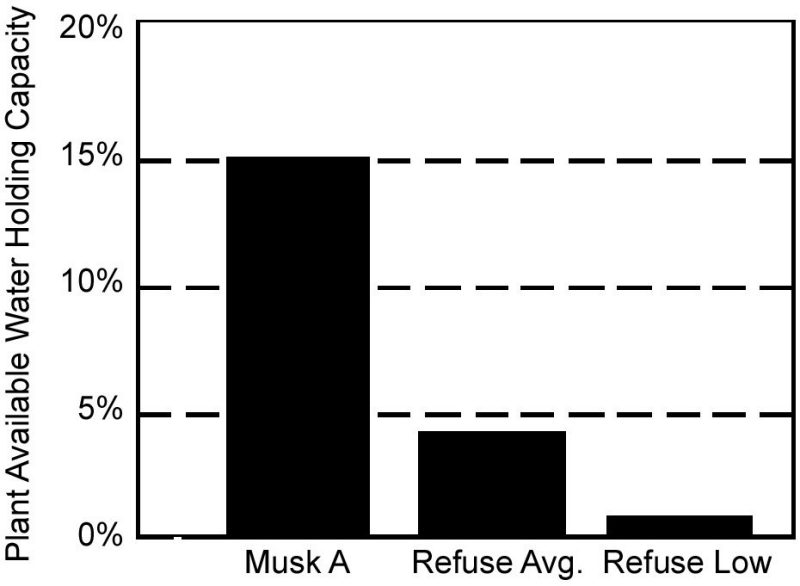

Moisture Retention, Rooting Depth, and Compaction

Inadequate plant-available moisture is a major problem with all mine spoils and refuse materials. The moisture-holding properties of a given refuse are directly related to its particle size distribution. Coal refuse is usually coarse in texture with a very low water-holding capacity (figure 5). Refuse materials in Virginia average 59 percent rock fragments (more than 2 mm), depending on length of exposure to weathering (table 2). As the average refuse particle size increases, the material’s moisture retention capacity is reduced. The exclusion of fine refuse from a fill will further reduce water-holding capacity. For this reason, it is desirable to place combined refuse (coarse plus fine) in the final revegetation surface if possible.

Plant roots are able to extract nearly all available water that is retained in the rooting zone of refuse (usually the upper 24 inches) if potential acidity has been neutralized. There are a number of ways to increase moisture retention in coal refuse. The addition of organic amendments, heavy mulching, and the natural process of soil organic matter accumulation over time will all improve the water-supplying ability of coal refuse. We have frequently observed that the addition of only several inches of topsoil or similar finer spoil materials to an otherwise barren coal refuse material is all that is necessary to promote plant growth in cases where potential acidity has been neutralized. This occurs because the cover material improves water retention and supply. In older piles where weathering has taken place, the upper surface may contain very fine particles similar in texture to silt or clay; such materials will have higher moisture retention than coarse, fresh refuse. When revegetating older piles where soil cover is expensive or limited, weathered surface materials should be segregated prior to regrading and then reapplied to the pile as final cover.

Virginia mining regulations require that all regulated structures be designed for stability. Regulations governing coal refuse disposal (Virginia Administrative Code 4VAC25-130-816.83: Coal mine waste; Refuse piles) do not explicitly require compaction, but they do state, “Regular inspections … shall also be conducted during placement and compaction of coal mine waste material.” Excessive compaction has been identified as a major factor limiting reclamation success throughout the United States and will cause similar problems in coal refuse materials by limiting the available root-ing depth. Whenever possible (e.g., on near-level or mildly sloping surfaces where surface stability is not a major concern), the final lift or surface of the refuse pile should be left as loose as possible to enhance its potential to support plant growth.

High Surface Temperature

Coal refuse varies in color from light gray to black. Thus, much of the incoming solar radiation is retained as heat. Under sunny skies, the surface temperatures on the refuse surface may exceed air temperature by 30°F or more, depending on cloud cover and slope aspect. Surface temperature may fluctuate widely during the course of a day. Early morning temperatures may be higher than air temperatures due to heat retention within the pile, and this is also true of evening temperatures. On a warm cloudless day on a south-facing slope, the surface temperature may exceed 150°F. Surface temperatures in this range are lethal to plants, and legume seedlings are susceptible to heat kill at much lower temperatures.

Summary

The development of a successful coal refuse area reclamation strategy must take a number of factors and processes into account. Most importantly, the surface of the refuse must be manipulated and treated to overcome soil water-holding, temperature, and acidity problems. The revegetation strategy must be capable of producing a plant community that can withstand a wide range of harsh soil and microclimatic conditions. Finally, the steeply sloping surfaces of most refuse piles greatly complicate revegetation. Each area of the coal refuse fill must be carefully assessed for the properties and problems discussed above, and the final reclamation approach must be tailored accordingly.

Coal Refuse Reclamation Studies and Trials

Best results in reclamation of coal refuse piles have been achieved by incorporating lime and plant nutrients into a suitable soil cover above the refuse. In some cases, this is not possible due to the lack of available soil cover materials or the expense of transporting soil. Vegetation can be established directly on some refuse materials after amendment with lime and fertilizers.

The major question involved with direct-seeding strategies is whether or not the surface will remain hospitable for plants over extended periods of time. The establishment of a permanent legume component on refuse is particularly difficult. Improvement in vegetation establishment on bare refuse has been reported with high rates of organic amendments (composts or biosolids) in a number of states. Combinations of lime, mulching, heavy phosphorus, and biosolids treatments maintained vigorous vegetation for five full seasons in Southwest Virginia in Powell River Project trials on slightly acidic refuse materials (figure 6). Subsequent applications of these guidelines, conducted by mining firms working in cooperation with the authors, have demonstrated that these recommendations can be applied successfully at an operational scale.

How to Develop a Successful Refuse Reclamation Strategy

The successful long-term stabilization and reclamation of refuse piles is a difficult and complicated process. Reclamation strategies must be based on a thorough understanding of refuse and disposal site properties, how they will react to various treatments, and how the soil/plant system will change with time. Establishing a vigorous cover to stabilize the fill surface and reduce acid leachate production is critical.

Moisture stress, induced by high coarse-fragment contents, salts, and high surface heat, is the primary growth-limiting factor in most fresh coal refuse. As the materials weather, acidity becomes a major problem in some refuse, but acidity can be controlled to a large extent by liming. Many coal refuse materials can be successfully direct-seeded once their potential acidity has been neutralized through appropriate liming practices (figure 7).

Reagents and chemicals used in mineral processing may also limit plant growth in fresh wastes, but little is known about their effects. Once the coal refuse weathers and leaches for several years and its physical and chemical properties stabilize, it becomes easier to utilize as a plant-growth medium. Many of the older abandoned piles in the Appalachians are invaded by native pioneer vegetation after this stabilization occurs. Care should be taken not to disturb this fragile surface zone on older piles during reclamation, if possible.

The use of a reduced thickness of soil cover (less than 4 feet) to reclaim coal refuse has been successful in several experiments in Virginia and other states. Even thin (less than 1 foot) layers can provide enough water-holding capacity and suitable rooting environment for establishment of both grasses and legumes on moderately acidic wastes. Thicker covers may be necessary for long-term legume vigor on highly acidic refuse. The use of lime at the refuse/soil contact is essential when thin topsoil covers are employed; lime application rates should be based on the potential acidity of the underlying material. Where high surface temperature and low water supply are major problems, topsoiling also appears to be the best alternative for establishing a permanent vegetative cover. Direct-seeding appears feasible for refuse with low-to-moderate levels of acidity (figure 8), particularly when heavy agricultural lime, mulch, and other organic treatments, like composts or biosolids, are employed. Topsoiling with liming is the best alternative for highly acidic materials.

Revegetation strategies should establish a quick annual cover to rapidly provide shade and natural mulch for perennials. Any plant materials used on coal refuse must be capable of withstanding extreme short- and long-term changes in soil and site conditions. The importance of overcoming the heat- and water-holding limitations of bare refuse cannot be overemphasized. The combination of liming, fertilization, surface treatments, and seed-ing mix must be designed to rapidly establish an annual cover that will shade the surface and thereby improve soil moisture and temperature conditions.

The initial cover crop also takes up and holds essential plant nutrients against leaching and runoff and then returns these nutrients to the soil as it decomposes. The permanent perennial species then germinate and establish in the favorable microclimate provided by the cover crop. Once the perennial species are well-established (usually by the second year) and plant/soil nutrient cycles have become established, the chances for long-term reclamation success (and bond release) are greatly improved. Over the years, we have observed many vigorous stands of annual cover crops on direct-seeded coal refuse materials. However, diverse self-sustaining stands of perennial grasses and legumes after multiple seasons are much more difficult to achieve.

Guidelines for Refuse Revegetation in Southwest Virginia

The guidelines that follow represent our best recommendations for the stabilization and revegetation of refuse piles in Southwest Virginia. They have been provided to VDMLR for consideration and have been used successfully by a number of mining firms. It is important that these guidelines be used in consultation with regulatory authorities; use of these guidelines without regulatory agency concurrence may lead to permit violation, particularly with regard to topsoiling or fertilizer augmentation requirements. These guidelines are based upon Powell River Project cooperative research work at multiple sites since 1983 and our interpretations of relevant literature.

Refuse Characterization

Our studies indicate that many refuse materials can be direct-seeded or successfully reclaimed with reduced topsoil depth if and only if their physical and chemical properties are well-understood. The two most important properties are water-holding capacity and potential acidity. Therefore, in order to use our classification system (table 3), data on these parameters and how they vary across the reclamation surface must be obtained.

Accounting (ABA) |

Lime Recommendation |

Amendments and Seeding Strategies |

|---|---|---|

<10 tons/acre net acid, >20% finesb |

Lime to ABA need |

Direct-seed with heavy phosphorus, straw mulch, and organic amendments if possiblec. Use refuse seed mixture (table 4). |

10-25 T/Ac net acid, >20% finesb |

Lime to ABA, split if necessary |

Direct-seed with heavy phosphorus, straw mulch, and organic amendment (required)c. Use refuse seed mixture (table 4). |

25-50 T/Ac net acid |

Add lime (ABA need) at refuse-soil contact |

Topsoil cover with 6-18 inches of final depth. Use conventional lime, fertilizer, and seed. |

25-50 T/Ac net acidd |

Without lime at soil contact |

Topsoil cover with 24 inches or more final depth. Use conventional lime, fertilizer, and seed. |

>50 T/Ac net acid |

Add lime (ABA need) at refuse-soil contact |

18-24 inches of final topsoil depth. Use conventional lime, fertilizer, and seed. |

a These recommendations do not take sideslope seeps and springs into account. Such seeps are usually acidic; affected areas will need to be spot treated.

b Refuse materials with less than 20 percent particles of less than 2 mm (less than 20 percent fines) should be topsoiled.

c Organic amendment consisting of stabilized sewage sludge, papermill sludge, composted wood chips, or similar material with a carbon-to-nitrogen ratio less than 30, at a rate of at least 35 dry tons per acre, incorporated with a chisel plow.

d On flat and gently sloping surfaces, lime and organic amendments may be applied in several treatments. Splitting lime applications so as to allow it to react with the acidic refuse prior to seed application may allow direct-seeding on materials of up to 50 tons per acre net ABA acidity. This can occur only on near-level to moderately sloped areas.

Particle-size distribution should be determined by sieve analysis. Any refuse that is less than 20 percent fines (less than 2 mm) will be difficult to reclaim regardless of acidity levels and should be topsoiled. It is possible to increase the water-holding capacity of coarse refuse with additions of organic amendments and fine-textured soils, as discussed later. Compaction is also a major factor in limiting water-holding in refuse materials. Therefore, for direct-seeding options, the surface 18 inches of refuse (or deeper) should be left uncompacted or should be ripped before seeding.

Potential acidity should be determined by a qualified laboratory using either the conventional acid-base accounting (ABA) method or the hydrogen peroxide oxidation technique. These two techniques give somewhat different estimates of the liming requirement for refuse materials (table 2); the peroxide oxidation technique is more conservative. Potential acidity or acid-base accounting results are typically reported in net tons of lime required per 1,000 tons of spoil or refuse tested. Given that an acre of refuse to a depth of 6 inches weighs approximately 1,000 tons, these figures equate to a field liming estimate in tons per acre. Simple measurements of pH are not valid for estimating refuse potential acidity because they do not account for unoxidized pyritic sulfur and/or the native lime content in the sample. The chemical reactions in the weathering refuse will cause the pH to change with time.

The ABA lime requirements should be considered as a bare-minimum lime application; additional quantities may be applied to help ensure success. Many experts in the field of acid mine drainage control advocate the use of several times the amount of lime prescribed by the ABA technique to ensure that the treated zone of acid-forming material is permanently stabilized. Studies have shown that in some cases, the rate of pyrite oxidation is so fast and the levels of iron plus acidity generated in solution are so high that a large excess of reactive lime is necessary to prevent the alkaline side of the balance from being overwhelmed.

Site Preparation

The preparation of a refuse disposal area for hydro-seeding should begin well in advance of actual seed-ing. Grading plans should minimize steep slopes where possible, provide equipment access for revegetation efforts, and reduce potential washes or rills from developing. The final lift of 2 to 3 feet of material should be left uncompacted or loosened with a ripper prior to the final grade.

Where possible, it is advisable to allow fresh refuse to lie exposed for a period of six months or more before seeding. During this time, refuse samples representative of areas to be seeded should be collected and analyzed for potential acidity, as discussed earlier. Depending on this analysis, agricultural lime or other suitable liming materials should be applied and incorporated two to three months before planting. It is possible to reduce the potential acidity of highly acidic materials (as discussed in table 3) by repeated additions of lime over an extended period. Should this method be used, it is recommended that no more than 25 tons per acre of lime be applied at any one time. Single applications using higher rates have been shown to suffer from iron coatings around larger-sized lime particles, rendering the lime ineffective unless the lime is thoroughly incorporated to a depth of 6 inches or more. Similar problems have been noted when coarse-textured liming materials have been utilized.

Sloping areas are of particular concern in site preparation. Often, lateral water flow through a pile will result in an acid seep or “hot spot” along the slope. These areas often appear chalky white during dry weather and may exhibit a pH less than 3.0. These hot spots should be pinpointed and treated heavily with lime where possible to prevent future problems in plant establishment.

Immediately prior to seeding, sloping areas should be prepared. The conventional approach is to “track” the slope with a dozer or other suitable equipment. If the site is tracked, that operation should be done in a manner that leaves narrow track depressions across the face of the slope. In practice, these tracks retain water, seed, and mulch during rains and are usually the first areas to show plant growth. However, a large body of revegetation literature clearly indicates that rough-graded slopes are much superior to tracked slopes for the prevention of short-term runoff and for the establishment of vegetation. This is particularly true of sites where forest establishment is required (VCE publication 460-123). Tracked slopes are also more compact than rough-graded slopes. In situations where surface stability is not a major concern, we strongly recommend only rough grading be applied to coal refuse disposal surfaces.

Fertilization

Because of the inherently low fertility of refuse, vegetation establishment requires the addition of nitrogen, phosphorus, and potassium fertilizers. Field trials and laboratory analyses have pinpointed phosphorus as being the most limiting nutrient to plant growth on these sites. If topsoil or a topsoil substitute material is to be used, a representative sample should be submitted to the Virginia Tech Soil Testing Laboratory (or a comparable commercial facility) for analysis. Please see VCE publication 460-121 for a discussion of fertilizer interpretations for mine soils.

As a base rate of fertilizer for direct-seeding, 100 pounds per acre of nitrogen, 350 pounds per acre of phosphorus (as P2O5), and 100 pounds per acre of potassium (as K2O) are recommended. To attain this high phosphorus level, it may be necessary to supplement conventional fertilizers (e.g., 10-20-10) with a high-phosphorus fertilizer like superphosphate. These rates are suggested when the seed mixture to be used contains legumes (clovers, trefoil, etc.) and they assume adequate establishment of legumes for continuing nitrogen availability in succeeding years, as discussed earlier.

When legumes are seeded, the appropriate inoculant should be added at the time of seeding (VCE publication 460-122). Care should be taken to keep the pH of the hydroseeder slurry buffered above 4.0 with lime.

The inoculant should be added to the hydroseeder tank immediately before seeding because the inoculant bacteria will perish if left in the high-salt environment of the hydroseeder slurry for more than a few minutes. If only grasses are to be used, the nitrogen rate should be adjusted upward to 150 pounds per acre, but the grasses will need additional nitrogen fertilizer in successive years in the absence of legumes.

Seeding Rates and Species Mixtures

Selection of species suitable for planting on refuse is complicated by the variability of the material. Therefore, it is imperative to use species that will tolerate a wide range of pH, moisture, and temperature conditions. Consideration should also be given to the time of year when seed is applied and to the overall goal of establishing a diverse and permanent vegetative cover. These criteria cannot be met by use of a single species mixture on all sites or under all conditions. Pow-ell River Project direct-seeding field trials, which were established using the above criteria, have been successful for five growing seasons and beyond on certain refuse materials.

Species mixtures and seeding rates detailed in table 4 appear to be suitable for direct-seeding of refuse and for use with topsoil covers. These recommendations were based on the conditions at our various research sites; the addition or deletion of species should be considered, depending on your local site conditions and seed availability. Each mixture contains species adapted to a variety of site conditions that are intended to overcome local minesoil variability problems and make the mixes usable on a variety of sites.

| Species | Latin Name | Rate (lb/acre) |

|---|---|---|

Redtop |

Agrostis alba |

3 |

Hard fescuea |

Festuca ovina |

20 |

Tall fescue |

Festuca arundinacea |

20 |

Annual ryegrass |

Lolium multiflorum |

15 |

German millet |

Setaria italica |

20 |

Weeping lovegrass |

Eragrostis curvula |

3 |

Birdsfoot trefoil |

Lotus corniculatus |

5 |

Yellow sweet clover |

Melilotus officinalis |

2 |

Ladino clover |

Trifolium repens |

2 |

Kobe lespedeza |

Lespedeza striata |

10 |

| Species | Latin Name | Rate (lb/acre) |

|---|---|---|

Redtop |

Agrostis alba |

3 |

Hard fescuea |

Festuca ovina |

20 |

Tall fescue |

Festuca arundinacea |

20 |

Annual ryegrass |

Lolium multiflorum |

15 |

Cereal rye |

Secale cereale |

25 |

Weeping lovegrass |

Eragrostis curvula |

3 |

Birdsfoot trefoil |

Lotus corniculatus |

5 |

Yellow sweet clover |

Melilotus officinalis |

5 |

Ladino clover |

Trifolium repens |

2 |

Kobe lespedeza |

Lespedeza striata |

10 |

aWhen using hard fescue, the varieties Scaldis or Reliant are recommended.

Spring seeding should occur after March 15 and before May 15 for optimal results (table 5); fall seeding is recommended between September 15 and November 15. Environmental conditions during the summer and winter are generally unfavorable for successful establishment of mixed perennial vegetation, and annual covers should only be seeded during these periods.

| Activity | Date | Recommendations |

|---|---|---|

| Final grading | May 15-Sept. 15 | Final grading should be done in a manner to avoid severe compaction of the surface. |

Liming |

Year-round |

Liming rate should be based on measured potential acidity. Single applications should not exceed 25 tons/acre. Additional lime may be added at threemonth intervals. |

Fertilization |

March 15-Nov. 15 |

If fertilizer is to be applied prior to seeding, nitrogen fertilizers should not be included. |

| Seeding | March 15-May 15 |

Apply complete spring seeding mixture with fertilizers. |

| Seeding | May 15-Sept. 15 |

Apply only millet with reduced rates of nitrogen. |

| Seeding | Sept. 15-Nov. 15 |

Apply complete fall seeding mixture with fertilizers. |

| Seeding | Nov. 15-March 15 |

Apply only cereal rye with reduced rates of nitrogen. |

Commercially available wood fiber or paper mulches at conventional application rates perform satisfactorily for their intended use — the establishment of grasses on topsoil. However, they are inadequate under the extreme environmental stresses on refuse piles. Our recommendation is that paper mulches be used at higher rates (more than 2,000 pounds per acre) in the hydro-seeder tank mix or in conjunction with straw mulch on refuse. Field trials indicate that using straw and wood fiber/paper mulches together greatly improves plant establishment and long-term vigor, particularly on hot, south-facing fills.

A technique that has proven successful in our work is as follows:

- When loading the hydroseeder, include paper mulch to achieve 1,000 to 1,500 pounds per acre, along with the desired amount of seed and fertilizer.

- Spray this mixture in such a manner that it covers twice the normal area usually covered with a single tank (in other words, apply at half the normal rate).

- Next, using a mechanical straw blower or manual spreader, spread straw to cover the area just sprayed. Good coverage is achieved with 2,500 pounds per acre of straw.

- Respray this area with the mulch/seed/fertilizer mixture in the same manner as indicated above.

By using this seeding method, several factors critical to successful establishment are ensured:

- The shade provided by mulch reduces water loss from the seedbed and shields young seedlings from the high temperatures common to these areas.

- The first tankful provides good seed/soil contact, which is necessary for good germination.

- The use of straw mulch over this initial tankful provides shade that reduces water loss and lowers surface temperatures.

- The addition of the final tankful adds more seed and water, which may infiltrate the straw mulch, while the paper mulch tacks the straw mulch in place by forming a mat-like surface.

While this technique adds to the cost and time involved, we feel that it is justified in terms of long-term establishment success, particularly on hot, droughty sites.

In summary, any direct-seeding should be done with heavy mulch, applications of at least 350 pounds per acre of P2O5, and normal rates of nitrogen and potassium, as discussed previously. Many direct-seeding alternatives may be impossible due to the difficulty of working amendments on steep fill faces. In these cases, some combination of lime and topsoil will be the only viable alternative.

Tree Planting

Currently, very little has been documented about the use of woody plants for the reclamation and revegetation of coal refuse. Industry experience indicates that black locust (Robinia pseudoacacia L.), white pine (Pinus strobus), and red pine (Pinus resinosa) can be successfully direct-hydroseeded onto conditioned refuse. Some success has also been achieved using containerized tree seedlings. Several tree species (e.g., black birch, Betula lenta) are known to successfully colonize old refuse piles, but seeds or seedlings of these species are not readily available commercially. Refer to VCE publication 460-123 for a detailed discussion of establishing forests on mined lands.

Native hardwoods can be used in coal refuse revegetation with a soil or topsoil substitute cover of adequate thickness. The cover should have physical and chemical properties suitable for the species to be planted. If the intent for planting the hardwoods is an expectation that they will remain in place over the long term, the soil cover should be at least 4 feet in thickness, and a thicker cover is preferred.

Post-Reclamation Management and Land Use

Current regulations require that the five-year bonding liability period begin after final reclamation and revegetation are completed. Except for practices typical for the specified post-reclamation land use, further augmentation of seed or soil amendments restarts the bonding period. When refuse disposal areas are being returned to unmanaged forest, augmentation is not considered by regulatory authorities to be a typical management practice. However, despite current regulations, we feel that augmentation, via split fertilizer applications or spot liming and seeding, is often necessary and should be a specified practice for the reclamation of coal refuse disposal areas via direct-seeding. Often, problem areas requiring this type of augmentation do not become apparent until the second or third growing season and may only cover a small area. While the area affected may not be large enough to preclude bond release, it may present a potential erosion or water quality threat in succeeding years. For this reason, augmentation treatment of these areas is encouraged.

Long-Term Water Quality Concerns

The long-term emission of acidic leachates from refuse piles is a major problem. These leachates present a much more difficult challenge than surface revegetation. To stop leachate production, water flow through the fill must be limited, but this is very difficult in a humid leaching environment such as Virginia’s.

There is evidence that a vigorous vegetative cover can reduce acid drainage by intercepting and transpiring rainfall, consuming oxygen in the rooting zone, and through several other mechanisms. However, the fundamental reaction thermodynamics of pyrite oxidation in the presence of water and oxygen cannot be ignored. Research has shown that establishment of a healthy vegetative cover alone cannot be expected to eliminate acid production and leaching from the interior of refuse piles.

While various treatments have been shown to slow the rate of the acid-producing pyrite weathering reactions, eventually the reactions will continue to completion. The mass of sulfur within most disposal areas far exceeds the neutralization potential of any surface-applied treatments. Thus, unless water is completely excluded from the fill, even moderately sulfidic refuse materials should be expected to discharge acidic leachates and long-term water treatment strategies should be planned. For net-acid-producing refuse piles, these discharges will generally continue well beyond the five-year bond liability period. For such piles, the leachates will have to be neutralized with caustic additions and/or acid-treatment wetlands.

Acid-treatment wetlands are not currently accepted by regulatory authorities as a “walk-away” solution to acid leachate water quality problems. Where sufficient land area is available, however, wetland treatment systems have proven to be a more cost-effective means of treating acid water than alkaline chemical systems. Lack of sufficient land area in the right location has proven to be a major barrier to use of acid-treatment wetlands. Proper placement and design in the landscape can allow refuse fills to utilize acid-treatment wetland systems as a cost-effective means of leachate water treatment. Design requirements of acid-treatment wetland systems as a cost-effective means of leachate water treatment. Design requirements of acid-treatment wetlands are reviewed in VCE publication 460-133.

The only technology that is known to be effective in eliminating the acid leachate potential at refuse disposal sites is the bulk blending of alkaline materials with the refuse as it is placed in the fill. Ground agri-cultural limestone serves this purpose well but may be required at mixture ratios of up to 5 percent. This would add a considerable cost to refuse disposal.

Our research has evaluated the potential to use alkaline fly ash as a lime substitute for acid neutralization in refuse piles. In general, we have seen positive net water quality results where alkaline loadings have been properly matched to the host coal refuse acid-producing potential. However, we have observed negative water quality results when the ash/refuse mixtures have been allowed to acidify to less than pH 4.0 or where too much alkaline addition resulted in very high (more than 9.0) bulk pH. It is also important to point out that not all fly ash materials are alkaline, and the net water quality impacts of blending ash and other coal combustion byproducts, such as scrubber sludges, with acid-forming refuse materials must be carefully considered. Details on the use of coal combustion byproducts in mined land reclamation are given in VCE publication 460-134.

Reprocessing and Remediation of Older Refuse Piles

Hundreds of pre-SMCRA coal refuse piles exist in the Virginia coalfield. Those of recent vintage are being or have been reclaimed to post-SMCRA environmental standards, and their coal content is often much less than the older piles that were created prior to the advent of improved coal separation technologies as well as the SMCRA. These older piles are the source of current concern for several reasons, including potential uses for the marketable coals that some contain and the environmental impacts of the older piles, especially those subject to erosion and close to surface water streams (figure 2). As a result, there is a new emphasis on cleaning up these older piles for both coal recovery and environmental remediation purposes (figure 9).

Such operations commonly occur under the jurisdiction of either Title IV (Abandoned Mine Reclamation) or Title V (which regulates active mining) of SMCRA. As such, reclamation and revegetation of the refuse remediation site and of any refuse or reprocessing residue (such as scalp rock) that is either left on the reprocessing site or disposed of elsewhere is required. The cost and amount of soil cover material required for successful reclamation of these areas can be reduced if the operation identifies the refuse materials that are most favorable to revegetation and saves those materials for use in the revegetation process.

This material segregation can often be done without great difficulty because the most favorable materials are typically those that occur on the surface of the refuse pile, where long-term exposure to air and rainfall has caused them to weather and become more like soil materials than the underlying refuse.

In order to take advantage of these materials, we recommend that they be identified and characterized prior to any disturbance. For reprocessing operations, the most logical time to do this is during the initial characterization of the material from various locations in the pile. As this process occurs, we recommend that a sample of the upper surface material also be retained and characterized for its revegetation potential. The more-weathered material is usually the best for revegetation, and this material can usually be identified visually because it has been discolored by the weathering process; it may extend for several feet into the pile. This material can be characterized for chemical properties, including pH, potential acidity, and particle size, and evaluated using the guidelines of table 3. If volunteer plants are growing on the pile surface, this is an indication that the materials have favorable properties for revegetation.

When checking refuse properties, be aware of the potential for elevated temperatures inside the pile. If high temperatures are observed, notify the Virginia Division of Mined Land Reclamation immediately. Although spontaneous combustion of coal refuse rarely occurs, it sometimes happens. At least one fire in a Virginia abandoned mine land (AML) refuse pile occurred when the surface material was disturbed in advance of potential reprocessing, allowing atmospheric oxygen to access the pile interior where elevated temperatures had built up due to precombustion oxidation processes. The vast majority of Virginia coal refuse piles do not suffer from this condition but caution is warranted because of the few that do. Coal refuse materials containing significant quantities of combustible carbon should not be used for direct-seeding due to the potential for accidental combustion that may be caused by lightning, vandalism, or other means.

Summary and Recommendations

The Appalachian coal industry has made great progress in coal refuse reclamation over the past 20 years. However, further improvements are needed to ensure that the industry is not faced with significant long-term liabilities. Refuse disposal areas should be designed and constructed with long-term stabilization and water quality concerns in mind. In particular, fill hydrology and its interaction with pyrite weathering and seepage should be considered when designing and constructing refuse fills. The surface reclamation strategy should be designed to maintain a vigorous plant cover and to neutralize surface acidity and water-holding limitations over time. Excessively steep slopes are very difficult to treat as is needed to establish permanent vegetation and should be minimized where possible. The land area requirements of constructed wetland water treatment strategies, which are capable of reducing the long-term costs of leachate water treatment, should be considered infill design.

The long-term acid generation potential of a refuse pile must be taken into account during reclamation and closure planning. Currently, bulk blending of lime or other alkaline materials is the only viable long-term approach for controlling or eliminating the release of acid mine drainage by acidic refuse.

Even after the pile has been reclaimed and revegetated, either with or without topsoil cover, most coal refuse disposal sites should be considered as potential environmental liabilities, with restricted public access and protection from disturbance. A surface disturbance that exposes underlying materials can create erosion hazards if those exposed materials fail to revegetate quickly and naturally. If the pile contains pyritic mate-rials, any activity that opens the pile surface and allows oxygen and water to enter the interior can renew or accelerate pyrite oxidation. Coal refuse materials are predominantly of natural geologic origin and — due to the effects of environmental processes over time — will eventually become benign, but the potential liabilities associated with reclaimed coal refuse piles can be expected to last for decades or longer. Over those time scales, the piles should remain protected.

Acknowledgments

This paper summarizes the collective work and insights of a number of people working with us on the Powell River Project coal refuse research study. Katie Haering, Vince Ruark, Jay Bell, and Dennis Dove all contributed immeasurably to our understanding of this problem through their collective efforts. We wish to thank a number of individuals who were working with the coal industry at the time of this research, including Eddie Hannah, Mark Singleton, Ken Roddenberry, Steve Sutphin, Ron Keene, and Roger Jones. We also thank a number of mining firms for their generous help and cooperation throughout our studies, including Jewell Smokeless, the former Westmoreland Coal, United Coal, Paramont Mining (now Alpha Natural Resources), and Consolidation Coal (now Consol Energy). We also received invaluable help in the field from Ron Alls, the late Ren-sheng Li, and Velva Groover. The research that allowed us to reach this level of understanding was supported by the Powell River Project, the Virginia Center for Innovative Technology, and the former U.S. Bureau of Mines.

References

Powell River Project/Virginia Cooperative Extension (VCE) Publications

Burger, J. A., and C. E. Zipper. How to Restore Forests on Surface-Mined Land. VCE publication 460-123.

Daniels, W., B. Stewart, K. Haering, and C. E. Zipper. The Potential for Beneficial Reuse of Coal Fly Ash in Southwest Virginia Mining Environments. VCE publication 460-134.

Daniels, W. L., and C. E. Zipper. Creation and Management of Productive Mine Soils. VCE Publication 460-121.

Skousen, J., and C. E. Zipper. Revegetation Species and Practices. VCE publication 460-122.

Zipper, C. E., J. Skousen, and C. Jage. Passive Treatment of Acid-Mine Drainage. VCE publication 460-133.

Other References

Daniels, W. L., and B. A. Stewart. 2000. Reclamation of Appalachian coal refuse disposal areas. In Reclamation of Drastically Disturbed Lands. Agronomy.

No. 41, Chapter 17. Ed. R. I. Barnhisel, R. G. Dar-mody, and W. L. Daniels. Madison, Wis.: American Society of Agronomy.

Helmke, P. A. 1999. The chemical composition of soils. In Handbook of Soil Science. Ed. M. E. Sumner. Boca Raton, Fla.: CRC Press.

National Research Council (NRC), National Academy of Sciences. 1979. Redistribution of Accessory Elements in Mining and Mineral Processing, Part I. Washington, D.C.: National Academy Press.

Nawrot, J., and B. Gray. 2000. Principles and practices of tailings reclamation: Coal refuse. In Reclamation of Drastically Disturbed Lands. Agronomy No. 41, Chapter 18. Ed. R. I. Barnhisel, R. G. Dar-mody, and W. L. Daniels. Madison, Wis.: American Society of Agronomy.

Rose, J. G., T. I. Robi, and A. E. Bland. 1976. Composition and properties of refuse from Kentucky preparation plants. In Proceedings, Fifth Mineral Waste Utilization Symposium, 122-31. Chicago: U.S. Bureau of Mines and ITT Research Institute.

Stewart, B. R., and W. L. Daniels. 1992. Physical and chemical properties of coal refuse from Southwest Virginia. Journal of Environmental Quality 21:635-42.

Virginia Department of Mines, Minerals and Energy. Virginia Administrative Code, Title 4, Agency 25, Chapter 130, Section 816.83 (Coal mine waste; refuse piles). http://leg1.state.va.us/000/reg/TOC.HTM.

Additional Resources

Buttermore, W. H., E. J. Simcoe, and M. A. Maloy. 1978. Characterization of Coal Refuse. Technical Report No. 159, Coal Research Bureau. Morgan-town: West Virginia University.

Daniels, W. L., and D. C. Dove. 1987. Revegetation strategies for coal refuse areas. In Proceedings, Eighth Annual West Virginia Surface Mine Drainage Task Force Symposium, F1-13. West Virginia Surface Mine Drainage Task Force. Morgantown: West Virginia University.

Daniels, W. L., K. C. Haering, and D. C. Dove. 1989. Long-term strategies for reclaiming and managing coal refuse disposal areas. Virginia Coal and Energy Journal 1 (1): 45-59.

Daniels, W. L., K. C. Haering, B. R. Stewart, R. V. Ruark, and D. C. Dove. 1990. New technologies for the stabilization and reclamation of coal refuse materials. In Proceedings, 1990 Powell River Project Symposium, 1-20. Powell River Project. Blacksburg: Virginia Tech.

Davidson, W. A. 1974. Reclaiming refuse banks from underground bituminous mines in Pennsylvania. In Proceedings, First Symposium on Mine and Preparation Plant Refuse Disposal. National Coal Association and Bituminous Coal Research, Coal Conference and Expo II. Washington, D.C.: National Coal Association.

Dove, D. C., W. L. Daniels, and J. Bell. 1987. Reclamation of coal wastes with reduced soil depth and other amendments. In Proceedings, Fourth Annual Meeting of the American Society for Surface Mining and Reclamation, L1, 1-9. Princeton, W.Va.: ASSMR.

Jastrow, J. D., A. J. Dvorak, M. J. Knight, and B. K. Mueller. 1981. Revegetation of Acidic Coal Refuse: Effects of Soil Cover Material Depth and Lim-ing Rate on Initial Establishment. ANL/LRP-3. Argonne, Ill.: Argonne National Laboratory.

Joost, R. E., F. J. Olsen, and J. H. Jones. 1987. Revegetation and minesoil development of coal refuse amended with sewage sludge and limestone. Journal of Environmental Quality l6 (1): 91-94.

Nickerson, F. H. 1984. Vegetative cover grows directly on acidic mine refuse pile. Coal Mining & Processing (February 1984): 39-43.

Robl, T. L., A. E. Bland, and J. G. Rose. 1976. Kentucky coal refuse: A geotechnical assessment of its potential as a metals source. In Preprints, Second Symposium on Coal Preparation, 152-59. National Coal Association and Bituminous Coal Research, Coal Conference and Expo III. Washington, D.C.: National Coal Association.

Schramm, J. R. 1966. Plant colonization studies on black wastes from anthracite mining in Pennsylvania. New Series: Vol. 56, Part 1 of Transactions of the American Philosophical Society. Philadelphia: American Philosophical Society.

Stewart, B. R. 1990. Physical and Chemical Properties of Coarse Coal Refuse From Southwest Virginia. M.S. thesis, Crop and Soil Environmental Sciences, Virginia Tech.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

July 25, 2023