Understanding Pre-harvest Sprouting of Wheat

ID

424-060

EXPERT REVIEWED

What is Pre-harvest Sprouting?

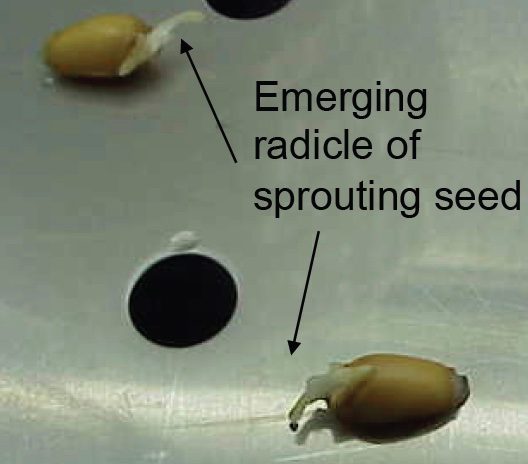

Germination of wheat within the grain head before harvest is called pre-harvest sprouting (PHS). Periods of prolonged rainfall and high humidity after the grain has ripened and before it can be harvested can contribute to PHS, which can be thought of as a premature germination. Germination can begin as a wheat kernel absorbs moisture and swells. Visible indications of PHS include kernel swelling, germ discoloration, seed-coat splitting, and the root and shoot emerging (figure 1). Pre-harvest sprouting results in lower yields due to decreased test weights, and it limits end-use applications for wheat due to decreased grain quality. Reduced grain quality, coupled with decreased yields, can result in substantial financial losses to farmers and food processors.

Three to four weeks after flowering, wheat grains reach maximum size and then begin to lose water as the ripening process begins. While the starchy endosperm cells die at this point, those of the seed-coat layer and embryo remain alive but dormant. Normally this dormancy keeps the seeds from beginning to sprout while still in the seed head. However, environmental conditions during grain development affect the degree of resistance to PHS. In general, grain is more dormant (less likely to have PHS) when produced under cool conditions. Higher temperatures during the later stages of grain fill can result in lower grain dormancy, and this lower dormancy can make sprouting within the head, i.e., PHS, more likely if rain occurs prior to harvest. Individual grains within the seed head may have slightly different water availability and dormancy levels. Therefore, only a portion of the grains in an individual head, or the heads within a crop, may exhibit PHS.

How is Sprouting Damage Measured?

A “falling-number test” measures alpha-amylase activity within a grain sample. Alpha-amylase is an enzyme that breaks down starch within germinating seeds. Starch breakdown is desirable if the seed has been planted and needs to produce a seedling; however, alpha-amylase activity in PHS – where we really didn’t want the seeds to germinate – can greatly reduce flour quality. (Flour is mostly starch, and alpha-amylase reduces important flour qualities.) Falling-number tests are conducted by creating a slurry of flour and water in a test tube. The time required for a plunger to fall through the slurry is measured. Sound, starchy grain produces a thick slurry (and a bigger falling number). Sprout-damaged grain will result in a flour and water mixture that is thinner or less viscous, because alpha-amylase has begun to break down the starch. The faster the plunger falls to the bottom of the test tube, the lower the viscosity of the mixture and the smaller the falling number. Lower falling numbers indicate there have been higher levels of alpha-amylase activity. Falling numbers, then, are an indirect but quite accurate measure of PHS.

In general, falling-number values less than 250 seconds to 300 seconds indicate flours that are of poor quality for milling and baking purposes. Flour from sprout-damaged wheat, i.e., wheat that has experienced PHS and that produces flour with lower falling numbers, can affect mixability, crumb strength, sliceablity, and loaf volume. Wheat that does not meet the minimum falling-number standard is unsuitable for milling and is usually sold to the livestock feed market. Since flour-quality wheat generally receives a significant premium over feed wheat, low falling-number wheat represents a loss to the producer.

Pre-harvest Sprouting Susceptibility

Resistance to PHS depends on factors influencing water uptake and drying rate of the grain, grain dormancy, and the remobilization of nutrients to support germination. These factors are controlled by a number of genes that strongly interact with environmental conditions. The level of grain dormancy at maturity is perhaps the biggest factor determining the differences in sprouting observed among different wheat lines.

Pre-harvest Sprouting and Environment

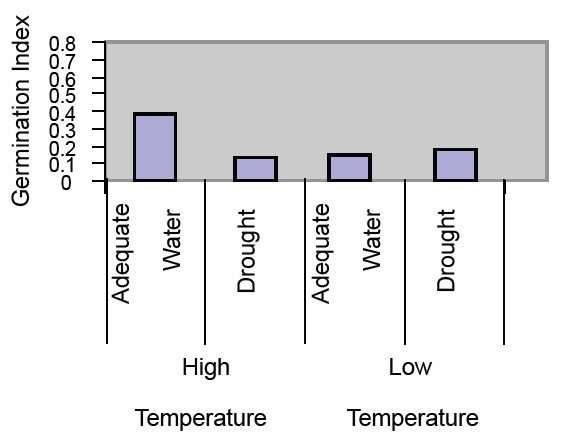

Environmental conditions both before and after seed maturity influence the rate of PHS. Before maturity, the effect of temperature on sprouting depends on the cultivar and water availability. Drier conditions generally produce seed with lower sprouting tendency. Cooler temperatures just prior to maturity also result in seed with higher dormancy and less sprouting, especially in combination with dry conditions (figure 2).

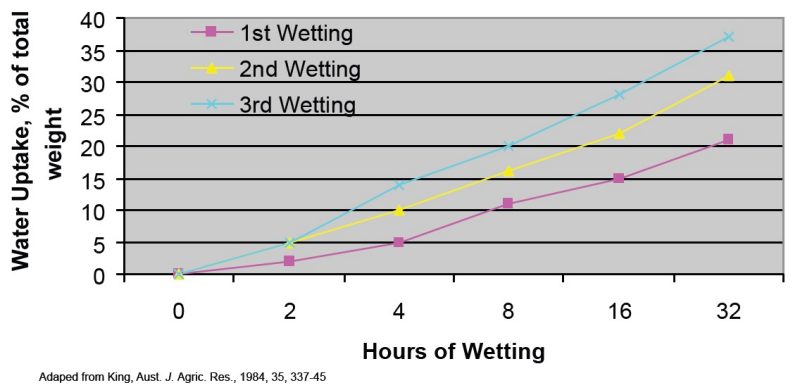

Cool, moist conditions after maturity lead to increased PHS. Also, the more wetting and drying cycles the seed experiences, the more likely it is to break dormancy and sprout in the head (figure 4). Water must penetrate the seed coat and move into the seed before it can germinate. Following multiple wetting and drying cycles, it becomes easier for more water to soak into the seed more quickly.

This type of “weathering” decreases grain test weight, which is another important component of wheat quality evaluation. The decrease in grain test weight is presumably due to the early germination processes that cause starchy materials in the seed to be metabolized (consumed) by the embryo whether it actually germinates or not. This loss of starch results in loss of kernel weight.

Pre-harvest Sprouting and Crop Morphology

Morphological characteristics such as awn length, head angle, spike shape, and glume tenacity (figure 3) affect the amount of moisture that the grain head can absorb.

Wheat lines with heads that remain upright tend to shed more moisture than those that bend parallel with the ground or turn downward, resulting in less sprouting (table 1).

“Glume tenacity” refers to how tightly the glume, or outer covering, of the grain holds to the seed during grain dry down. Lines with low glume tenacity tend to allow more moisture to contact seed. Awnless or shortawned lines also typically take up less moisture, making them less prone to PHS. These effects are secondary to genetic and environmental controls; however, it is possible to directly select for these traits and develop less susceptible PHS lines.

| Head angle (degrees) | Heads with sprouting (per 10 heads) |

|---|---|

| 79.7 | 9.5 |

| 82.3 | 7.8 |

| 84.8 | 6.0 |

Adapted from King, R.W., and P. von Wettstein-Knowles. 2000. Epiticular waxes and regulation of ear wetting and pre-harvest sprouting in barley and wheat. Euphytica 112:157–166.

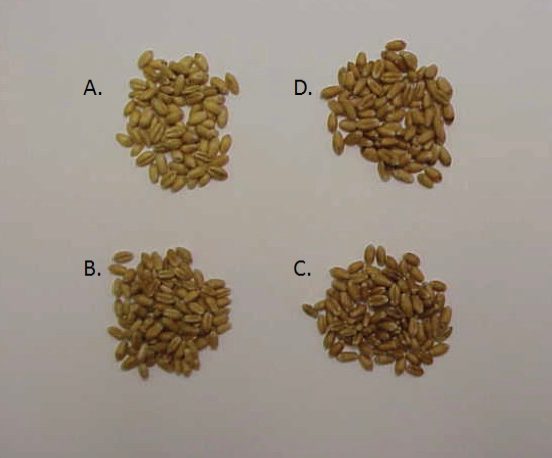

Pre-harvest Sprouting and Seed- Coat Color

Earlier studies have demonstrated that PHS is partially controlled by genetics. Lines with white seed-coat color are generally more susceptible to sprouting than those with red seed coats. Red and white refer to the color of the seed pericarp (seed coat), which is controlled by three independent genes (figure 5). Research supports the conclusion that the genes that control PHS are associated with – or nearby on the chromosome to – the genes for seed-coat color, so that when breeders select for white seed coats, they are also indirectly selecting for lower inherent dormancy. All three separate genes for seed-coat color must be homozygous for white to produce wheat with a white seed coat. Red color is dominant to white, thus a single red gene results in some red color. The degree of red color is additive, meaning that wheat lines with three red genes produce the darkest red seed. Generally, dormancy is higher in these lines with higher numbers of red seed-coat genes. There is some variation between lines that have the same number of red genes due to the different forms of the genes. There are also genes controlling dormancy that are independent of the color genes.

Inherent Dormancy

Most wheat lines exhibit some degree of dormancy after harvest and require a period of “after-ripening” before germination can occur. After-ripening usually happens within a few weeks after harvest, while seed are in storage. In cases of PHS, the after-ripening essentially occurs while in the seed head – i.e., weathering – setting the stage for PHS.

Inherent dormancy of most current soft red, winter- wheat lines has been evaluated in growth-chamber studies. This information can be found on the Virginia Corn and Small Grain Management website at: www. grains.cses.vt.edu. As just described, these scores are influenced by a number of environmental factors and should not be interpreted as predicting the likelihood of PHS in a particular year; however, relative differences among cultivars are representative of differences that exist when exposed to similar conditions. Some cultivars are, in fact, less likely to develop PHS and may tolerate greater weathering prior to harvest.

Management Options

Weathering of grain, principally due to rainfall after maturity, can lead to PHS. To minimize PHS and test-weight losses, harvest and then dry wheat the first time it reaches 20 percent moisture, or – if drying is not possible – harvest it the first time it reaches 15 percent moisture. Make sure the combine and all other critical equipment including hauling capacity are “ready to roll.” Try not to let other steps in the harvesting chain limit the combine capacity per day. Set the combine properly and modify the cylinder speed and/or concave clearance as harvest conditions change during the day. Timely harvest is absolutely critical if milling-quality wheat is to be produced.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture, and local governments. Its programs and employment are open to all, regardless of age, color, disability, sex (including pregnancy), gender, gender identity, gender expression, genetic information, ethnicity or national origin, political affiliation, race, religion, sexual orientation, or military status, or any other basis protected by law.

Publication Date

August 7, 2024