Growing Hulless Barley in the Mid-Atlantic

ID

424-022

EXPERT REVIEWED

Introduction

Demand for high energy, low fiber grain by the vertically integrated swine and poultry industries and the availability of brewers’ and distillers’ grains for the beef and dairy industries have greatly reduced the market for traditional barley. In an effort to recapture a share of this feed market, there has been an emphasis placed on the development of the more energy dense hulless type of barley. Meanwhile, increased interest in the use of hulless barley cultivars in the manufacturing of food and fuel products has accentuated the desire to develop winter hulless barley varieties for both domestic and foreign markets. Additionally, barley grain contains health-related compounds similar to those found in oats, adding to its appeal in the health-food sector. The use of barley in ethanol production may soon become a reality and will provide a viable market for hulless barley produced in the Mid-Atlantic Region. To date, significant progress has been made in the development of winter hulless barley lines. Continued efforts will be focused on the development of hulless barley varieties for specific end-use markets benefiting producers in the Mid-Atlantic Region.

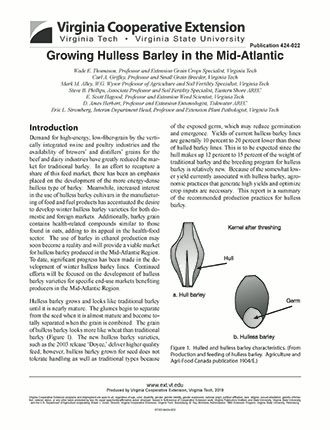

Hulless barley grows and looks like traditional barley until it is nearly mature. The glumes begin to separate from the seed when it is almost mature and become totally separated when the grain is combined. The grain of hulless barley looks more like wheat than traditional barley (Figure 1). The new hulless barley varieties, such as the 2003 release ‘Doyce,’ deliver higher quality feed; however, hulless barley grown for seed does not tolerate handling as well as traditional types because of the exposed germ, which may reduce germination and emergence. Yields of current hulless barley lines are generally 10 percent to 20 percent lower than those of hulled barley lines. This is to be expected since the hull makes up 12 percent to 15 percent of the weight of traditional barley and the breeding program for hulless barley is relatively new. Because of the somewhat lower yield currently associated with hulless barley, agronomic practices that generate high yields and optimize crop inputs are necessary. This report is a summary of the recommended production practices for hulless barley.

Seeding Rates

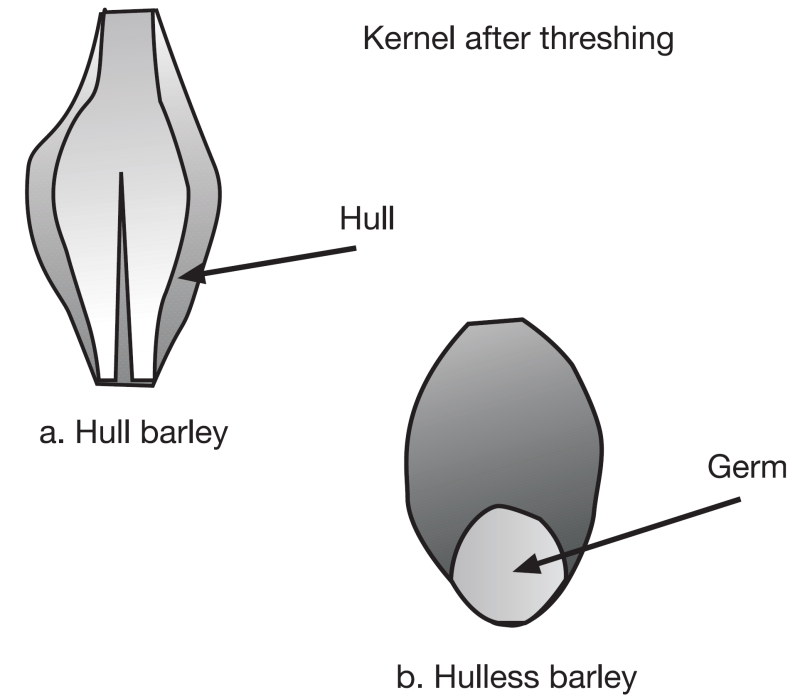

Potential damage to the germ of hulless barley due to the lack of a hull for protection necessitates a higher seeding rate. Results from testing at Warsaw, Blacksburg, and Chatham, Va., from 2003 through 2005 (Figure 2) demonstrate that seeding rates for hulless barley in a conventional, tilled seedbed should be at least 40 seeds per square foot (23 seeds per row foot in 7.5-inch rows) to approach optimum yields. Initial results support the conclusion that seeding at 45 to 50 seeds per square foot is appropriate for sites with high yield (>85 bushels per acre) potential. Increased seeding rates are advisable when planting later than optimum and/or with no-tillage planting. Growers saving seed from a previous hulless barley crop should have a germination test performed on all seed lots.

Fertilizer

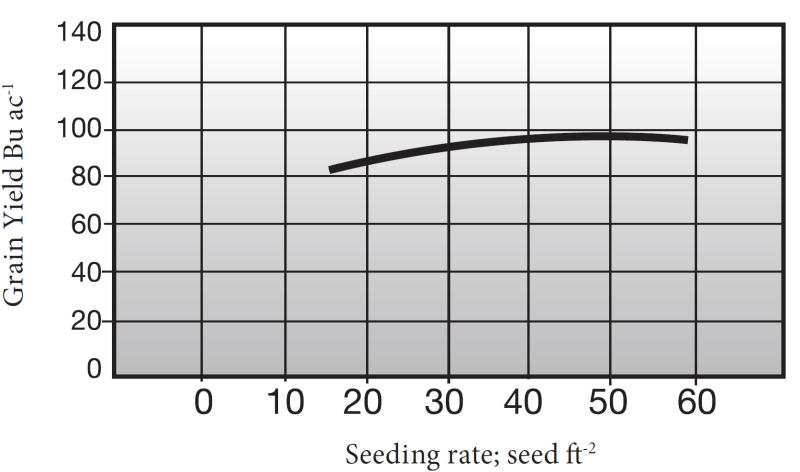

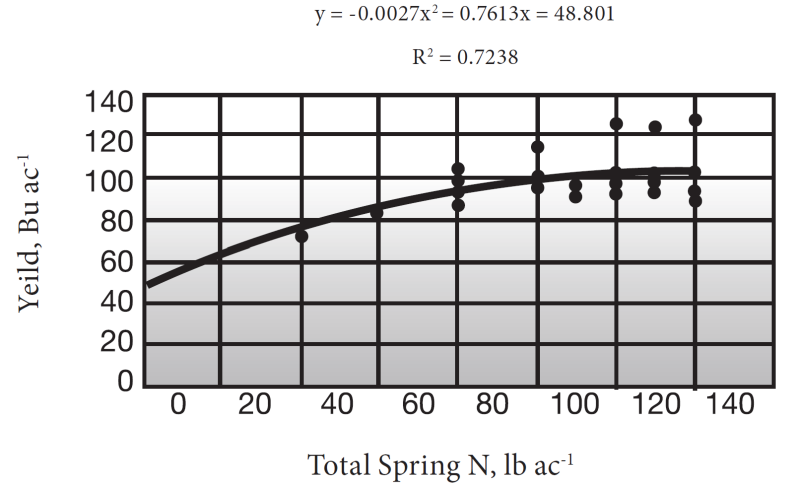

Lime, phosphorus, and potassium recommendations should be the same for hulled and hulless barley. Barley, in general, does not tolerate low soil pH. Barley should receive adequate nitrogen (N), 25 to 40 pounds per acre, at planting to encourage early growth. If significant leaching rains occur in early winter or if the crop has a pale green color in January, an application of 25 pounds N per acre is appropriate at that time. The crop should be evaluated at Zadoks growth stage (GS) 25 for tiller density. Apply 50 pounds N per acre if there are fewer than 50 tillers per square foot at this time. No N is needed if there are more than 150 tillers per square foot and the crop is green. Do not apply more than 50 pounds N per acre in February if a GS 30 N application is planned. Leaf tissue samples collected at GS 30 should be analyzed to determine the appropriate topdress N rate. Figure 3 illustrates the relationship between leaf tissue N concentration and recommended N rate at GS 30.

Total N applications at GS 25 plus GS 30 should not exceed 100 pounds N per acre due to increased likelihood of lodging. This recommendation matches results from trials conducted in 2004 and 2005 where near optimum yields were achieved with total spring N rates near 100 pounds per acre (Figure 4).

Further information about sampling techniques and crop growth stages can be found in Nitrogen Fertilization of Winter Barley: Principles and Recommendations, Virginia Cooperative Extension publication 424-801, http://pubs.ext.vt.edu/424-801/.

Weed Management

All herbicides that have a label for traditional barley (eg. Harmony Extra, Harmony GT, Peak, 2,4-D, Hoelon) are acceptable for use in hulless barley. See the latest edition of the Pest Management Guide, Field Crops, Virginia Cooperative Extension publication 456-016, http://pubs.ext.vt.edu/456-016/ or your local Extension agent for specific information on appropriate herbicides and application strategies. While Osprey® herbicide is a good control option for Hoelon-(diclofop-) resistant Italian ryegrass in winter wheat, this product is NOT registered for use in barley, either hulled or hulless. The best option is to keep barley plantings away from areas with Hoelon-resistant ryegrass.

Disease Management

In field tests, ‘Doyce’ has expressed high levels of resistance (assessed on a scale of 0 to 9, where 0=resistant and 9=susceptible) to leaf rust, with an average score of 1.0 compared to 7.7 for H585 and 3.0 for ‘Callao.’ ‘Doyce’ also has expressed resistance to powdery mildew (0.1), Septoria speckled leaf blotch (2.0), and Barley Yellow Dwarf Virus (BYDV). ‘Doyce’ is slightly more susceptible (4.0) to net blotch than ‘Callao’ (3.0) or ‘Nomini’ (2.0). Net blotch should not cause economic problems with ‘Doyce’ most years, but evaluate fields closely in April. Heavy infection with net blotch can result in reductions in grain yield, test weight, seed plumpness, and brightness. Fields should be scouted frequently for the prevalence of disease and fungicides should be applied according to recommended disease threshold levels. Though low to moderate disease pressure may not significantly reduce grain yields, the use of a fungicide may be warranted to maintain grain quality because diseases such as net blotch can result in reductions in kernel plumpness and brightness. See the latest edition of the Pest Management Guide, Field Crops, Virginia Cooperative Extension publication 456-016, http://pubs.ext.vt.edu/456-016/ or your local Extension agent for specific information on appropriate fungicides and application strategies.

Insect Management

Little is known about the susceptibility of current hulless barley varieties to insect pests; however, it is safe to assume that hulless barley will have many of the same pests as traditional barley. Barley generally is more susceptible to BYDV because it is planted earlier than wheat, which makes the young plants available to migrating fall aphid populations. Barley generally is less susceptible than wheat to cereal leaf beetle because it is more mature than wheat when cereal leaf beetle adults lay their eggs. Cereal leaf beetle pressure tends to be heavier in areas of least vegetation, such as late-planted wheat. Growers and crop advisors should scout fields regularly and report any unusual insect problems to their local Extension offices or to specialists because less is known about this relatively new small grain.

Lodging Management

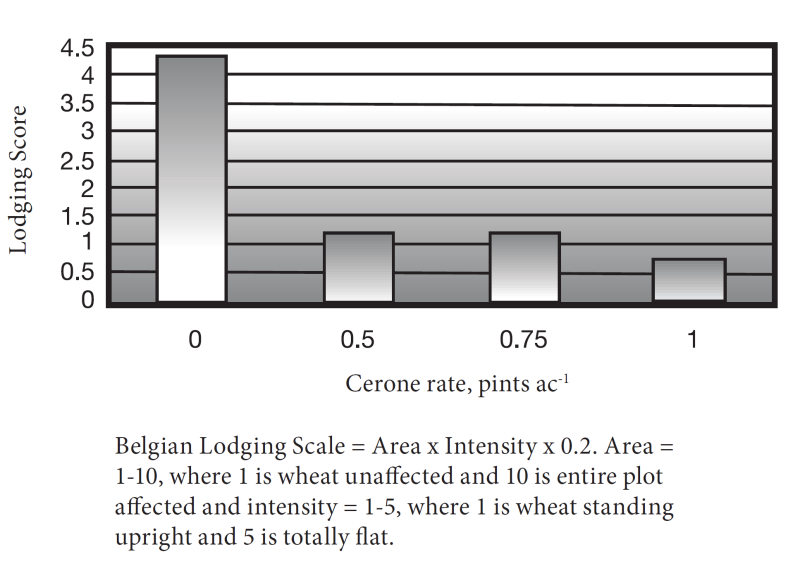

‘Doyce’ hulless barley’s straw strength and tolerance to lodging are superior to both those of ‘Callao’ and ‘Nomini.’ A growth regulator (Cerone®) should be considered for use on highly productive soils when spring N rates exceed 100 pounds N per acre. Cerone® should not be applied if the crop is experiencing moisture stress or high temperatures (above 85°F) are expected during or immediately after applications. Refer to the label for timing and rates of application. In 2005, ‘Doyce’ exhibited moderate lodging in trials at the Eastern Shore Agricultural Research and Extension Center (AREC) when no growth regulator was applied, but lodging was greatly reduced when Cerone® was applied at rates of 0.5 pints per acre or greater (Figure 5).

Harvest Management

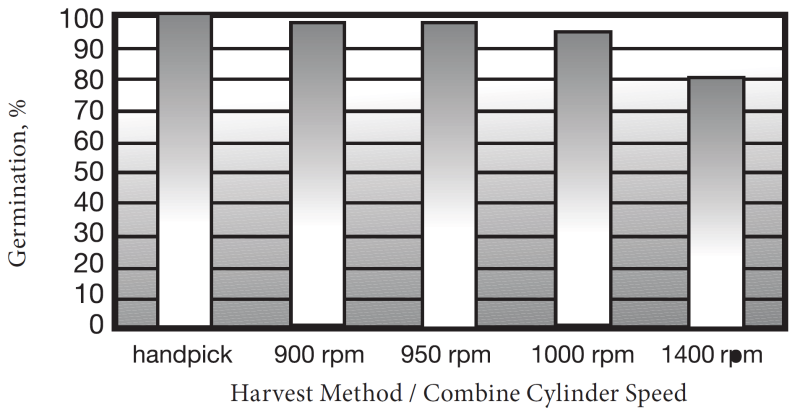

Harvest timing and maturity are similar to hulled barley. Care must be taken during harvest to optimize combine settings (concave setting and cylinder speed) to minimize grain cracking and damage to the unprotected germ. Hulls, or glumes, detach much more readily from mature grain. Figure 6 shows the decrease in germination due to damage from increased combine cylinder speed with handpicked heads considered 100 percent. Higher cylinder speeds will break and damage seeds. Hulless barley should be combined more like wheat than traditional barley.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

June 24, 2024